How do I set My Spindle CW/CCW output to be momentary?

- SteveCorr

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 3

I am currently only looking to have the motor run forward or reverse at the standard 60hz as I have a variable speed head that I can use to control the actual spindle speed. Yes I do intend to get an encoder on that spindle, but it's not going to happen until my experience as a machinist is at a point where I need it. This is my first mill and I do feel like I jumping right into the deep end by buying a running mill and gutting it to make it a LinuxCNC mill.

Part of the reason I am choosing to run the motor at 60 hz is because the motor was built in '82 which was before drive rated motors were really a thing, and I know that drives are hard on motors and can destroy non drive rated motors. So my thinking is if I run the drive at 60 hz the way the motor was originally intended to run my chances of it surviving longer are better.

The motor is a Tai Chin Electric Co 2ho 3 phase 220v induction motor.

the mill is a Supermax YCM-1-1/2VS, I think, the label is inaccessible behind the control cabinet. When I bought it it had an Anilam 3000m on it but that was an upgrade to the original Anilam Crusader 1100?

What I thought was cool is it is still rock solid and had been barely used over its 39 year life span

https://drive.google.com/file/d/1jZMHDmQ6g4VWjEmiB1mf2E76QcHauloJ/view?usp=sharing

Please Log in or Create an account to join the conversation.

- SteveCorr

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 3

You nailed my plans. Thank you for the explaining this, you said it much more clearly then I didOnly I am wondering about this 60Hz. 400Hz is usual and maximum voltage is set with parameter F05.

It's a Supermax mill - like a Bridgeport. Has a pretty standard 3p induction motor and likely a nameplate frequency of 60hz (1800rpm). The speed control as the OP mentioned is a variable pulley system. You crank a knob/wheel on the side (only when motor is running) to adjust the speed up and down (opens/closes the variable pitch pulleys).

It might have a two-speed motor and/or a back-gear like some Bridgeports, but the OP would have to report back on that one. These sorts of arrangements can be a little tricky to get under full CNC control - hence the OP's earlier statement about a spindle encoder.

With a direct spindle encoder he could, in theory, attach a stepper motor to the pulley adjustment wheel and have LCNC start the main motor and a gentle PID loop would adjust the pulley ratio until an AT-SPEED signal was met before continuing the program.

The motor has one speed but the head has a high speed and a low speed, and to get the low speed the motor runs in reverse.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

- Posts: 529

- Thank you received: 140

Please Log in or Create an account to join the conversation.

- SteveCorr

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 807

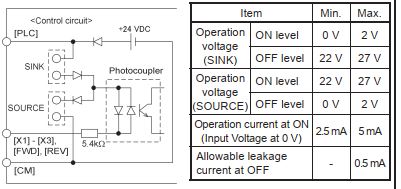

The digital inputs on the VFD aren't 'contacts' in the traditional sense. They're transistors (see diagram). More imoprtantly, the VFD was designed to use either the 3-wire control you've got now, or a 2-wire control. They will not 'burn out' with extended use like an overloaded relay.I'm concerned that the dry contacts in the drive may have problems when I hold that forward/ reverse signal closed for an extended amount of time, as those inputs were intended to be momentary contacts.

https://drive.google.com/file/d/1jZMHDmQ6g4VWjEmiB1mf2E76QcHauloJ/view?usp=sharing

When I (or someone else) is referring to dry contacts, we're talking about whatever external device is making the connection between a digital input terminal and the DI COM terminal. A switch, relay, or whatever. You could just connect two bare wires together if you wanted

The point is that you aren't supplying or sinking any external voltage to/from the VFD when you connect a digital input to the digital input COM.

Attachments:

Please Log in or Create an account to join the conversation.

- SteveCorr

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 3

Thank you

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 807

Don't forget you can use some additional relays to trigger different spindle speeds. A cheat sheet taped to the head for 30/60/90hz (or whatever) would be easy. And LOW/MED/HI screen buttons might not be too hard to set up. No touching the varispeed - just three pre-set speeds.

And the issue with older motors is that they can overheat at low speed/high load situations. Don't be afraid to use the VFD to fiddle the speed a bit. 30hz to 90hz should be pretty safe if you aren't running a giant drill or face mill for a long time.

Please Log in or Create an account to join the conversation.