- LinuxCNC

- General LinuxCNC Questions

- How can I modify G76 to make it actually useful for internal threading?

How can I modify G76 to make it actually useful for internal threading?

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

26 Feb 2022 17:56 #235855

by radom

How can I modify G76 to make it actually useful for internal threading? was created by radom

Is it possible to modify G76 so it actually stays on the drive line when doing retract path?

I have been using G33 for internal threading ever since because with G76 with every cutting pass you end up retracting further away for the driveline, so when you have small clearance between tool holder and bore diameter you end up running tool holder into the work after few retract passes

so now for whatever reason I want to use G76, can I modify source code to make that work properly?

I have been using G33 for internal threading ever since because with G76 with every cutting pass you end up retracting further away for the driveline, so when you have small clearance between tool holder and bore diameter you end up running tool holder into the work after few retract passes

so now for whatever reason I want to use G76, can I modify source code to make that work properly?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

26 Feb 2022 20:02 #235866

by Clive S

If you can post the code As I can check it on my lathe.

I don't see any problems with G76.

Replied by Clive S on topic How can I modify G76 to make it actually useful for internal threading?

Is it possible to modify G76 so it actually stays on the drive line when doing retract path?

I have been using G33 for internal threading ever since because with G76 with every cutting pass you end up retracting further away for the driveline, so when you have small clearance between tool holder and bore diameter you end up running tool holder into the work after few retract passes

so now for whatever reason I want to use G76, can I modify source code to make that work properly?

If you can post the code As I can check it on my lathe.

I don't see any problems with G76.

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

27 Feb 2022 10:27 #235900

by radom

Replied by radom on topic How can I modify G76 to make it actually useful for internal threading?

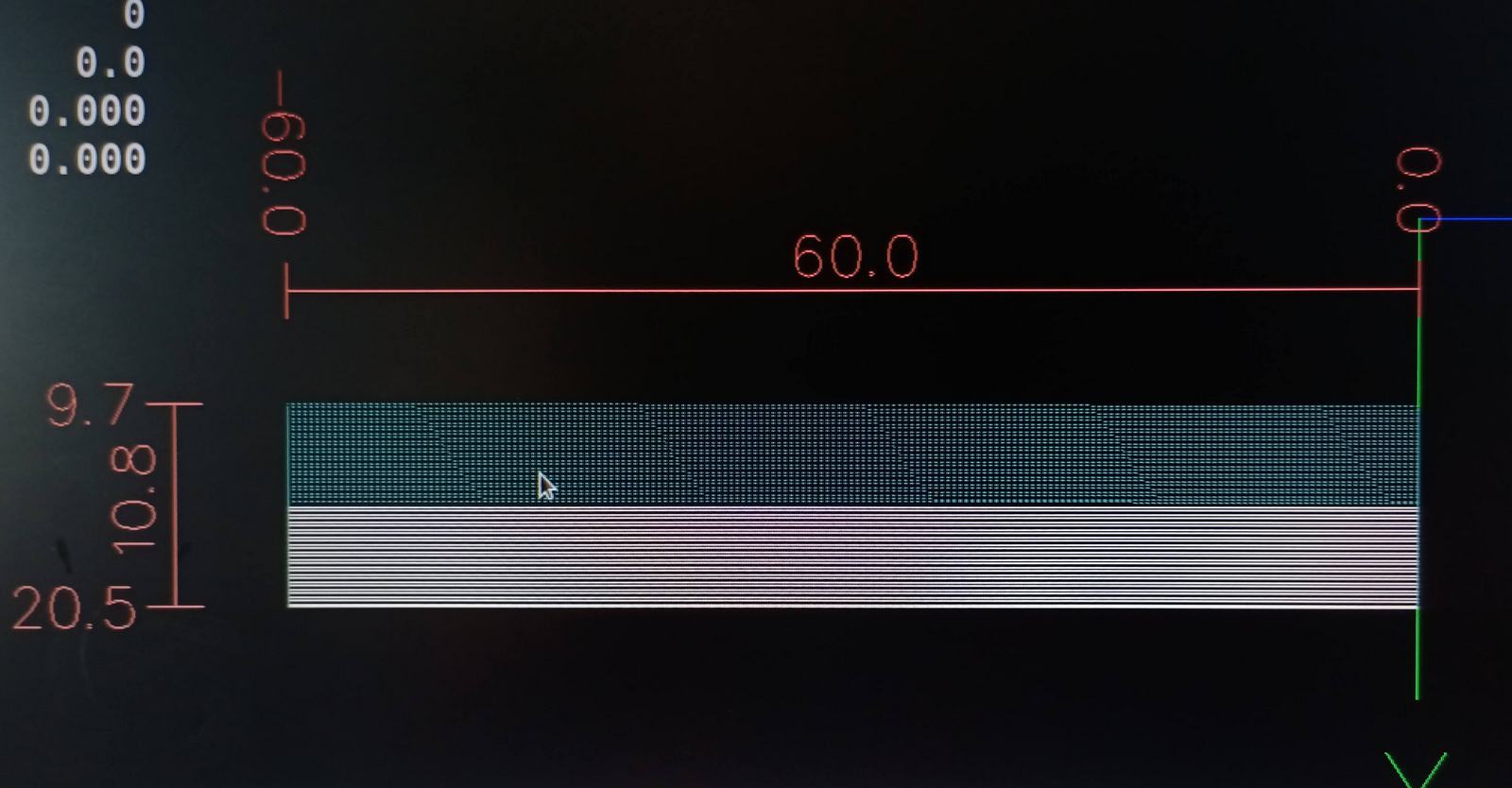

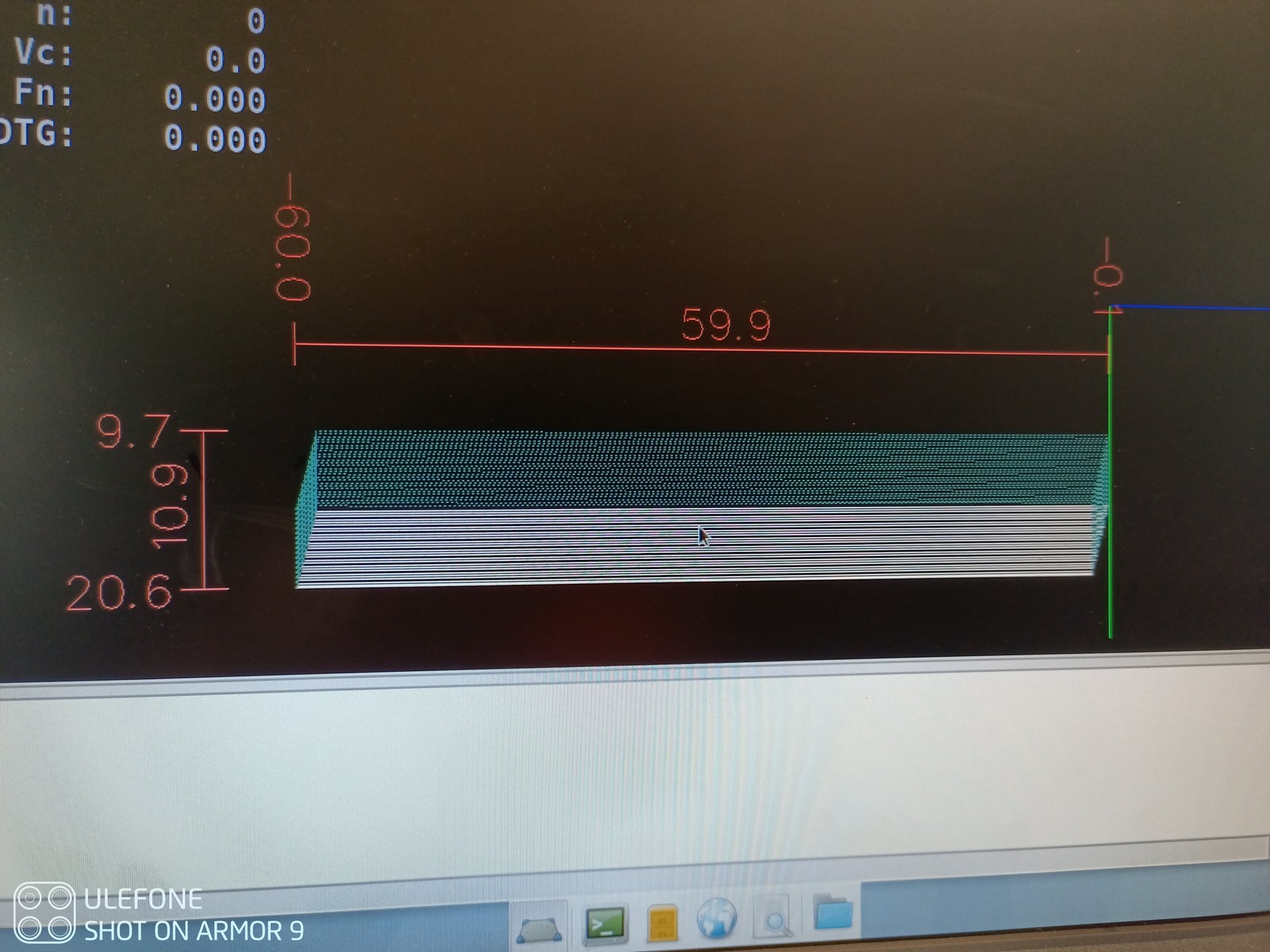

Attachments:

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

27 Feb 2022 18:24 #235937

by Clive S

Replied by Clive S on topic How can I modify G76 to make it actually useful for internal threading?

Re:-

g76 p10 z-60 i0.1 j0.4 k11

I think it should be G76 P10 Z-60 I-0.1 J0.4 K10

Figure 3. G76 Threading

g76 p10 z-60 i0.1 j0.4 k11

I think it should be G76 P10 Z-60 I-0.1 J0.4 K10

Figure 3. G76 Threading

- Drive Line - A line through the initial X position parallel to the Z.

- P- - The thread pitch in distance per revolution.

- Z- - The final position of threads. At the end of the cycle the tool will be at this Z position.

- I- - The thread peak offset from the drive line. Negative I values are external threads, and positive I values are internal threads. Generally the material has been turned to this size before the G76 cycle.

- J- - A positive value specifying the initial cut depth. The first threading cut will be J beyond the thread peak position.

- K- - A positive value specifying the full thread depth. The final threading cut will be K beyond the thread peak position.

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

27 Feb 2022 18:47 #235941

by radom

Replied by radom on topic How can I modify G76 to make it actually useful for internal threading?

no, I'm cutting internal thread

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17630

- Thank you received: 5158

27 Feb 2022 23:20 #235956

by PCW

Replied by PCW on topic How can I modify G76 to make it actually useful for internal threading?

I may not understand but I think the retract drive line is moved

parallel to the cut driveline to equalize the sync time available

before the tool starts cutting.

parallel to the cut driveline to equalize the sync time available

before the tool starts cutting.

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

28 Feb 2022 08:16 #235995

by radom

Replied by radom on topic How can I modify G76 to make it actually useful for internal threading?

Ok I found solution for my problem,

11 years ago

www.mail-archive.com/emc-developers@list...ge.net/msg04863.html

now only if I knew how to recompile the source

11 years ago

www.mail-archive.com/emc-developers@list...ge.net/msg04863.html

now only if I knew how to recompile the source

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21231

- Thank you received: 7249

28 Feb 2022 10:23 #236000

by tommylight

Replied by tommylight on topic How can I modify G76 to make it actually useful for internal threading?

It should be on the documents page, getting LinuxCNC or the likes, look for run in place.

Sorry, on the phone so not much help.

Sorry, on the phone so not much help.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

28 Feb 2022 11:47 #236007

by Clive S

Thank you I did not know it was doing that as I do not do much internal threading with tight bore.

Please post the answer here if you can.

Replied by Clive S on topic How can I modify G76 to make it actually useful for internal threading?

Ok I found solution for my problem,

11 years ago

www.mail-archive.com/emc-developers@list...ge.net/msg04863.html

now only if I knew how to recompile the source

Thank you I did not know it was doing that as I do not do much internal threading with tight bore.

Please post the answer here if you can.

Please Log in or Create an account to join the conversation.

- radom

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 7

01 Mar 2022 11:25 #236092

by radom

Replied by radom on topic How can I modify G76 to make it actually useful for internal threading?

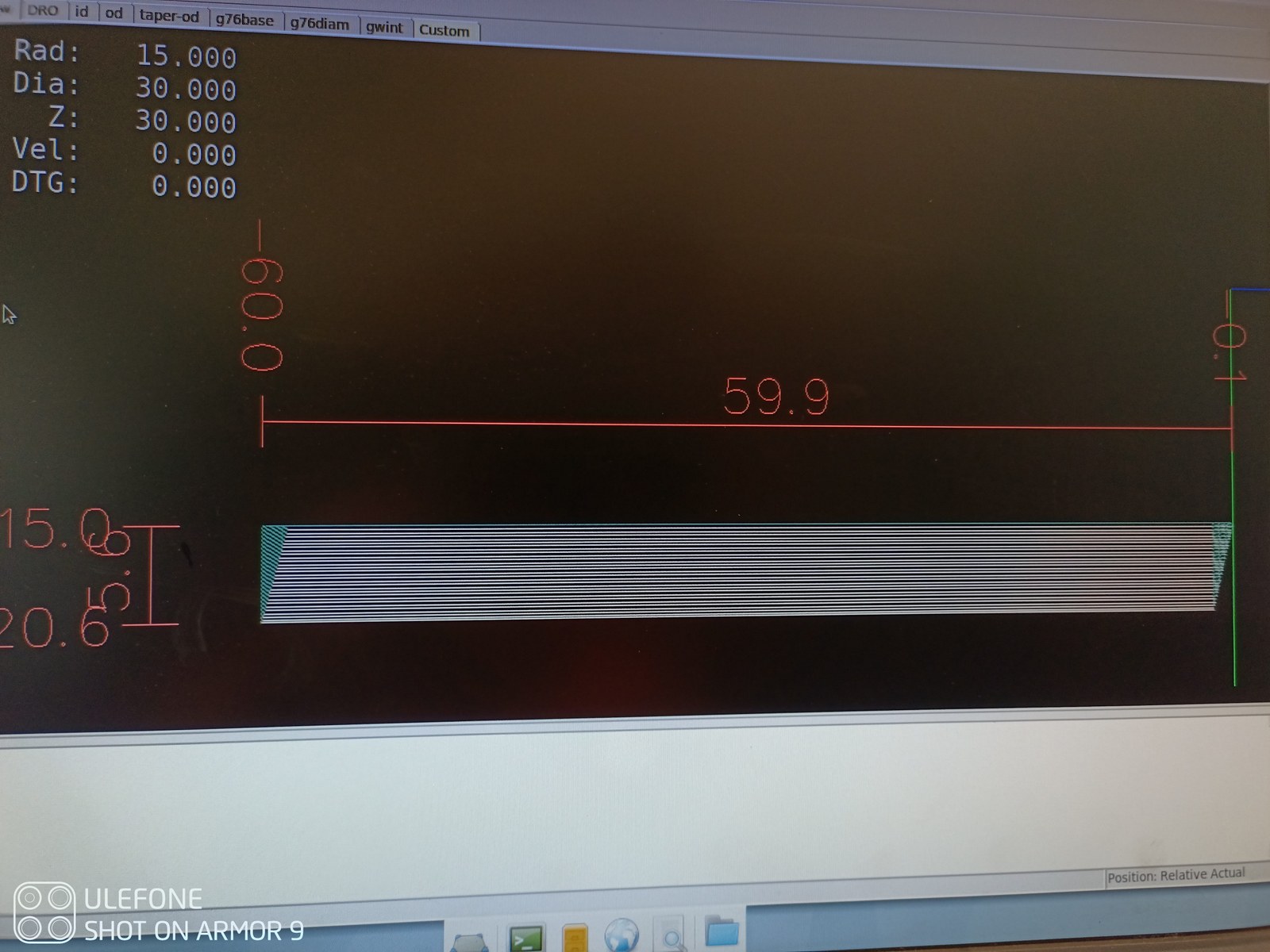

Attachments:

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- How can I modify G76 to make it actually useful for internal threading?

Time to create page: 0.126 seconds