Nema 23 power supply

- russkinch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

27 Feb 2022 22:39 #235950

by russkinch

Nema 23 power supply was created by russkinch

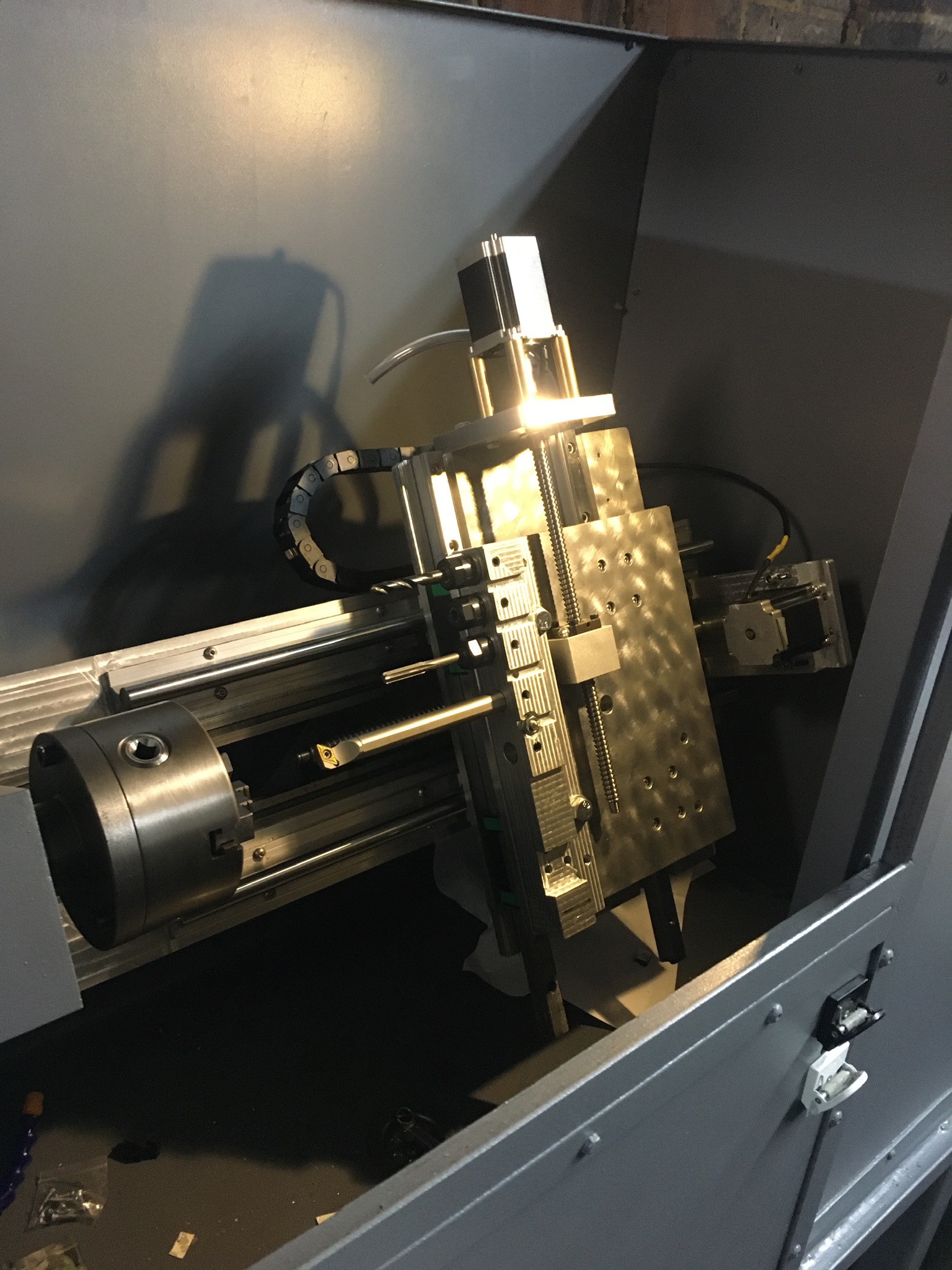

Hi. I have recently upgraded my machine and built it as a slant bed lathe. Roughly at 30 degrees. I have a 1.9Nm Nema 23 motor with a 5mm ball screw. Its powered by a 24v supply going through a MD430 driver. My issue is I think its loosing steps due to the weight of the cross slide ( not holding dimensions on X). Would a different driver and a 48v supply give it more torque and power? Below is my creation.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

27 Feb 2022 23:51 #235964

by rodw

Replied by rodw on topic Nema 23 power supply

Yes, 24 v power supply is inadequate. From memory, doubling voltage will quadruple available power. I learnt that the hard way just like you....

The following user(s) said Thank You: russkinch

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

28 Feb 2022 00:03 #235966

by BigJohnT

Replied by BigJohnT on topic Nema 23 power supply

The following user(s) said Thank You: russkinch

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21138

- Thank you received: 7221

28 Feb 2022 00:42 #235969

by tommylight

Replied by tommylight on topic Nema 23 power supply

Does that happen at very low speeds?

Besides above, using low inductance motors helps a lot.

Having a 12mH motor with 24V will not do much good. Not sure what yours are, but in general i use only low inductance ones.

Besides above, using low inductance motors helps a lot.

Having a 12mH motor with 24V will not do much good. Not sure what yours are, but in general i use only low inductance ones.

Please Log in or Create an account to join the conversation.

- Rosexing

-

- Visitor

-

28 Feb 2022 06:24 - 28 Feb 2022 22:44 #235988

by Rosexing

Replied by Rosexing on topic Nema 23 power supply

The driver is a wide voltage input. The same current increases the voltage power will increase a lot. The load that can be carried is much larger.

EDITED

Has nothing to do with the subject, it is spam for a chinese cnc machine company, link unhiden.

www.acctekgroup.com/cnc-router/

EDITED

Has nothing to do with the subject, it is spam for a chinese cnc machine company, link unhiden.

www.acctekgroup.com/cnc-router/

Last edit: 28 Feb 2022 22:44 by tommylight. Reason: Link

Please Log in or Create an account to join the conversation.

- russkinch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

28 Feb 2022 21:37 #236035

by russkinch

Replied by russkinch on topic Nema 23 power supply

My motors are 23HS8430P bi-polar (4 wire). If I increase the voltage to 48V and use DM542 drivers would this give me much more torque?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21138

- Thank you received: 7221

28 Feb 2022 22:50 #236053

by tommylight

Replied by tommylight on topic Nema 23 power supply

@Rosexing,

That is considered spam and is grounds for a permanent ban.

Since it is about cnc machines but has nothing to do with the subject, leaving it for now.

If you have anything to offer have the decency to post like a normal member, not hiding links and hijacking other topics with non related stuff.

Personally i will never ever buy anything from you, even if it is to save my life, just because of you tricking people.

P.S.

To much?

That is considered spam and is grounds for a permanent ban.

Since it is about cnc machines but has nothing to do with the subject, leaving it for now.

If you have anything to offer have the decency to post like a normal member, not hiding links and hijacking other topics with non related stuff.

Personally i will never ever buy anything from you, even if it is to save my life, just because of you tricking people.

P.S.

To much?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21138

- Thank you received: 7221

28 Feb 2022 22:58 #236058

by tommylight

Yes at higher speeds, but unknown at lower speeds.

Check the winding resistance on the motors, if it is 1 to 2 or even 3 Ohms per winding, then yes that will help at high speeds. but that also means something is not set correctly in your setup, from driver settings to mechanical binding issues or bent / not trammed rails.

Do keep in mind that high speed for stepper systems is anything above 200 to 500 RPM, depending on the size/torque/induction/inertia/voltage/drive system.

Even long thin cables from drive to motor will mess up the torque and speed.

Replied by tommylight on topic Nema 23 power supply

Yes and no.My motors are 23HS8430P bi-polar (4 wire). If I increase the voltage to 48V and use DM542 drivers would this give me much more torque?

Yes at higher speeds, but unknown at lower speeds.

Check the winding resistance on the motors, if it is 1 to 2 or even 3 Ohms per winding, then yes that will help at high speeds. but that also means something is not set correctly in your setup, from driver settings to mechanical binding issues or bent / not trammed rails.

Do keep in mind that high speed for stepper systems is anything above 200 to 500 RPM, depending on the size/torque/induction/inertia/voltage/drive system.

Even long thin cables from drive to motor will mess up the torque and speed.

Please Log in or Create an account to join the conversation.

Time to create page: 0.284 seconds