G-Code Fehler in axis.ngc

- klamos

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 0

14 May 2022 05:32 - 14 May 2022 05:38 #242939

by klamos

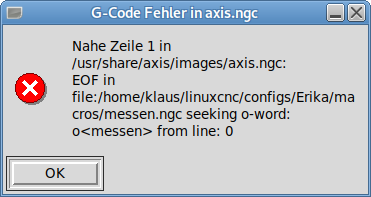

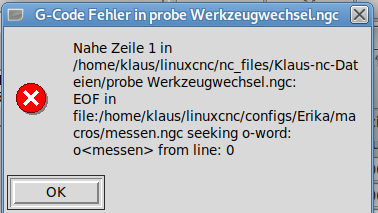

HAllo! Ich habe einen dynamischen Werkzeugwechsel eingerichtet und bekomme beim Start von der Maschine die erste G.Code Fehlermeldung und wenn ich mit ok bestätige, startet wohl die Maschine. Wenn ich eine G-Code Datei importiere kommt die 2. Fehlermeldung. Hat jemand eine Idee, was die Lösung sein könnte. Antwort bitte in Deutsch! Danke!

G-Code Fehler in axis.ngc was created by klamos

HAllo! Ich habe einen dynamischen Werkzeugwechsel eingerichtet und bekomme beim Start von der Maschine die erste G.Code Fehlermeldung und wenn ich mit ok bestätige, startet wohl die Maschine. Wenn ich eine G-Code Datei importiere kommt die 2. Fehlermeldung. Hat jemand eine Idee, was die Lösung sein könnte. Antwort bitte in Deutsch! Danke!

Attachments:

Last edit: 14 May 2022 05:38 by klamos.

Please Log in or Create an account to join the conversation.

- mgm

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 13

14 May 2022 06:26 - 14 May 2022 06:44 #242941

by mgm

Replied by mgm on topic G-Code Fehler in axis.ngc

Hallo Klaus,

Lass doch mal die beiden Dateien sehen!

Habe gerade im Deutschen Teil einen. ähnlichen Eintrag von Dir gelesen.

Lass mal Deine ini Datei sehen!

Lass doch mal die beiden Dateien sehen!

Habe gerade im Deutschen Teil einen. ähnlichen Eintrag von Dir gelesen.

Lass mal Deine ini Datei sehen!

Last edit: 14 May 2022 06:44 by mgm.

Please Log in or Create an account to join the conversation.

- klamos

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 0

14 May 2022 14:08 - 14 May 2022 14:10 #242951

by klamos

Replied by klamos on topic G-Code Fehler in axis.ngc

Hallo! Danke für deine Antwort:

Das sind die beiden Dateien, Vielleicht kannst du etwas finden.

Beste Grüße

Klamos

Das sind die beiden Dateien, Vielleicht kannst du etwas finden.

Beste Grüße

Klamos

Last edit: 14 May 2022 14:10 by klamos.

Please Log in or Create an account to join the conversation.

- mgm

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 13

15 May 2022 09:22 #243009

by mgm

Replied by mgm on topic G-Code Fehler in axis.ngc

Hallo Klaus,

Kannst Du auch noch Deine „ini“ Datei hier einstellen !

Gruß Michael

Kannst Du auch noch Deine „ini“ Datei hier einstellen !

Gruß Michael

Please Log in or Create an account to join the conversation.

- klamos

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 0

16 May 2022 07:53 #243068

by klamos

Replied by klamos on topic G-Code Fehler in axis.ngc

Hallo Michael!

Anbei sende ich dir die ini Datei. Vielleicht kannst du etwas finden, was mir weiterhilft. Wenn ich diesen Eintrag in

[RS274NGC] auskommentiere REMAP=M6 modalgroup=6 ngc=messen

dann erscheint der Fehler nicht mehr.

Danke!

Klaus

# Erstellt von PNCconf am Sun Jun 6 21:00:51 2021

# Using LinuxCNC version: 2.8

# Änderungen an dieser Datei werden beim nächsten

# overwritten when you run PNCconf again

[EMC]

MACHINE = Erika

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/klaus/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 25.000000

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

EMBED_TAB_NAME=Probe-Antasten

EMBED_TAB_COMMAND=halcmd loadusr -Wn gladevcp gladevcp -c gladevcp -u python/probe_screen.py -x {XID} probe_icons/probe_screen.glade

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

REMAP=M6 modalgroup=6 ngc=messen

FEATURES=30

SUBROUTINE_PATH = macros

[TOOLSENSOR]

# Control probe rapid speed

RAPID_SPEED = 600

# Absolute coordinates of the toolsensor pad

x = 280

y = 188

# Absolute Z start search coordinates

Z = -50

# Maximum search distance and direction (sign)

MAXPROBE =-50

# Speed of movements during working in Probe Screen

[CHANGE_POSITION]

# Abs coordinates tool change point

x = 280

y = 138

z = -50

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7i76e.0

[HAL]

HALUI = halui

HALFILE = Erika.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

HALFILE = chinahandrad.hal

[HALUI]

MDI_COMMAND = G10 L20 P0 X0 ( Set X to zero )

MDI_COMMAND = G10 L20 P0 Y0 ( Set Y to zero )

MDI_COMMAND = G10 L20 P0 Z0 ( Set Z to zero )

MDI_COMMAND = G10 L20 P0 A0 ( Set A to zero )

MDI_COMMAND=(debug,macro0) # this one is for numbering but not used by pendant (need 1 to 16)

MDI_COMMAND=(debug,macro1)

MDI_COMMAND=(debug,macro2)

MDI_COMMAND=(debug,macro3)

MDI_COMMAND=(debug,macro4)

MDI_COMMAND=(debug,macro5)

MDI_COMMAND=(debug,macro6)

MDI_COMMAND=(debug,macro7)

MDI_COMMAND=(debug,macro8)

MDI_COMMAND=(debug,macro9)

MDI_COMMAND=(debug,macro10)

MDI_COMMAND=(debug,macro11)

MDI_COMMAND=(debug,macro12)

MDI_COMMAND=(debug,macro13)

MDI_COMMAND=(debug,macro14)

MDI_COMMAND=(debug,macro15)

MDI_COMMAND=(debug,macro16)

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XYZA

[TRAJ]

COORDINATES = XYZA

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 2.00

MAX_LINEAR_VELOCITY = 20.00

POSITION_FILE = position.txt

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_WITH_SPINDLE_ON = 1

TOOL_CHANGE_QUILL_UP = 1

RANDOM_TOOLCHANGER = 1

#******************************************

[AXIS_X]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 800.0

MIN_LIMIT = -0.01

MAX_LIMIT = 280.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 750

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -800

MIN_LIMIT = -0.01

MAX_LIMIT = 280.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 3.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

MIN_LIMIT = -220.01

MAX_LIMIT = 0.01

[JOINT_1]

TYPE = LINEAR

HOME = -220.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 750

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800

MIN_LIMIT = -220.01

MAX_LIMIT = 0.01

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -3.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

MIN_LIMIT = -115.0

MAX_LIMIT = 0.01

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 750

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800

MIN_LIMIT = -115.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -3.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 0

#******************************************

#******************************************

[AXIS_A]

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 1200.0

MIN_LIMIT = -36000.0

MAX_LIMIT = 36000.0

[JOINT_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 1200.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 450

STEPGEN_MAXACCEL = 1500

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 26.6667

MIN_LIMIT = -36000.0

MAX_LIMIT = 36000.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 3

#******************************************

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

Anbei sende ich dir die ini Datei. Vielleicht kannst du etwas finden, was mir weiterhilft. Wenn ich diesen Eintrag in

[RS274NGC] auskommentiere REMAP=M6 modalgroup=6 ngc=messen

dann erscheint der Fehler nicht mehr.

Danke!

Klaus

# Erstellt von PNCconf am Sun Jun 6 21:00:51 2021

# Using LinuxCNC version: 2.8

# Änderungen an dieser Datei werden beim nächsten

# overwritten when you run PNCconf again

[EMC]

MACHINE = Erika

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/klaus/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 25.000000

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

EMBED_TAB_NAME=Probe-Antasten

EMBED_TAB_COMMAND=halcmd loadusr -Wn gladevcp gladevcp -c gladevcp -u python/probe_screen.py -x {XID} probe_icons/probe_screen.glade

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

REMAP=M6 modalgroup=6 ngc=messen

FEATURES=30

SUBROUTINE_PATH = macros

[TOOLSENSOR]

# Control probe rapid speed

RAPID_SPEED = 600

# Absolute coordinates of the toolsensor pad

x = 280

y = 188

# Absolute Z start search coordinates

Z = -50

# Maximum search distance and direction (sign)

MAXPROBE =-50

# Speed of movements during working in Probe Screen

[CHANGE_POSITION]

# Abs coordinates tool change point

x = 280

y = 138

z = -50

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7i76e.0

[HAL]

HALUI = halui

HALFILE = Erika.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

HALFILE = chinahandrad.hal

[HALUI]

MDI_COMMAND = G10 L20 P0 X0 ( Set X to zero )

MDI_COMMAND = G10 L20 P0 Y0 ( Set Y to zero )

MDI_COMMAND = G10 L20 P0 Z0 ( Set Z to zero )

MDI_COMMAND = G10 L20 P0 A0 ( Set A to zero )

MDI_COMMAND=(debug,macro0) # this one is for numbering but not used by pendant (need 1 to 16)

MDI_COMMAND=(debug,macro1)

MDI_COMMAND=(debug,macro2)

MDI_COMMAND=(debug,macro3)

MDI_COMMAND=(debug,macro4)

MDI_COMMAND=(debug,macro5)

MDI_COMMAND=(debug,macro6)

MDI_COMMAND=(debug,macro7)

MDI_COMMAND=(debug,macro8)

MDI_COMMAND=(debug,macro9)

MDI_COMMAND=(debug,macro10)

MDI_COMMAND=(debug,macro11)

MDI_COMMAND=(debug,macro12)

MDI_COMMAND=(debug,macro13)

MDI_COMMAND=(debug,macro14)

MDI_COMMAND=(debug,macro15)

MDI_COMMAND=(debug,macro16)

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XYZA

[TRAJ]

COORDINATES = XYZA

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 2.00

MAX_LINEAR_VELOCITY = 20.00

POSITION_FILE = position.txt

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_WITH_SPINDLE_ON = 1

TOOL_CHANGE_QUILL_UP = 1

RANDOM_TOOLCHANGER = 1

#******************************************

[AXIS_X]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 800.0

MIN_LIMIT = -0.01

MAX_LIMIT = 280.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 750

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -800

MIN_LIMIT = -0.01

MAX_LIMIT = 280.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 3.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

MIN_LIMIT = -220.01

MAX_LIMIT = 0.01

[JOINT_1]

TYPE = LINEAR

HOME = -220.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 750

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800

MIN_LIMIT = -220.01

MAX_LIMIT = 0.01

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -3.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

MIN_LIMIT = -115.0

MAX_LIMIT = 0.01

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 600.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 750

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800

MIN_LIMIT = -115.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -3.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

HOME_SEQUENCE = 0

#******************************************

#******************************************

[AXIS_A]

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 1200.0

MIN_LIMIT = -36000.0

MAX_LIMIT = 36000.0

[JOINT_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 1200.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 450

STEPGEN_MAXACCEL = 1500

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 26.6667

MIN_LIMIT = -36000.0

MAX_LIMIT = 36000.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 3

#******************************************

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

Please Log in or Create an account to join the conversation.

- mgm

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 13

16 May 2022 09:54 - 16 May 2022 09:57 #243073

by mgm

Replied by mgm on topic G-Code Fehler in axis.ngc

Hallo Klaus,

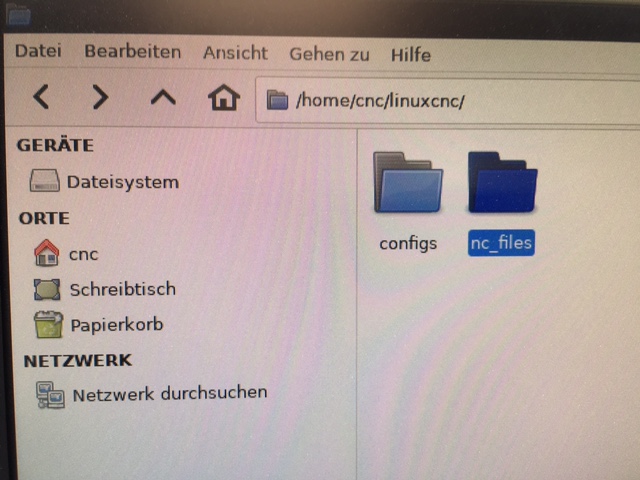

Du solltest neben dem ordner "configs" noch einen Ordner "nc_flies" haben.

Wenn Du

SUBROUTINE_PATH = macros

so in der ini eingetragen hast muss der Ordner "macros" mit der Datei "messen.ngc" in den Ordner "nc_files" eingetragen sein. Denn nur da sucht LCNC danach.

Im Ordner "nc_files" befinden sich normaler weise auch alle Fräsprogramme!

Hello Klaus,

You should have a folder "nc_flies" next to the folder "configs".

If you have

SUBROUTINE_PATH = macros

in the ini the file "messen.ngc" must be in the folder "nc_files". Because only there LCNC searches for it.

In the folder "nc_files" are normally also all milling programs!

Michael

Du solltest neben dem ordner "configs" noch einen Ordner "nc_flies" haben.

Wenn Du

SUBROUTINE_PATH = macros

so in der ini eingetragen hast muss der Ordner "macros" mit der Datei "messen.ngc" in den Ordner "nc_files" eingetragen sein. Denn nur da sucht LCNC danach.

Im Ordner "nc_files" befinden sich normaler weise auch alle Fräsprogramme!

Hello Klaus,

You should have a folder "nc_flies" next to the folder "configs".

If you have

SUBROUTINE_PATH = macros

in the ini the file "messen.ngc" must be in the folder "nc_files". Because only there LCNC searches for it.

In the folder "nc_files" are normally also all milling programs!

Michael

Attachments:

Last edit: 16 May 2022 09:57 by mgm.

Please Log in or Create an account to join the conversation.

- mgm

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 13

18 May 2022 18:23 #243290

by mgm

Replied by mgm on topic G-Code Fehler in axis.ngc

Und Fehler behoben?

Defect solved?

Defect solved?

Please Log in or Create an account to join the conversation.

- klamos

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 0

21 May 2022 09:41 #243467

by klamos

Replied by klamos on topic G-Code Fehler in axis.ngc

Danke Michael! Habe ich gemacht. Der Fehler lag am fehlenden % Zeichen am Beginn und Ende das Werkzeugwechsel G-Code Jobs

LG Klaus

LG Klaus

Please Log in or Create an account to join the conversation.

Time to create page: 0.111 seconds