Setting my workplace for milling

- jsvalentin

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 1

16 May 2022 19:36 - 16 May 2022 19:40 #243102

by jsvalentin

Setting my workplace for milling was created by jsvalentin

I have no idea how is done? I looked youtube and search document couldn't find it can you help me where to look?

I'm milling aluminum on APSX CNC and then I homed the cnc it goes back and home itself then i open gcode and move my cnc manually cnc axis to front to the aluminum spot and put it on corner of xy on left side of material then i hit start and it goes back to homed spot and start there when shouldnt be there.. How do i reset the xyz and set up my offset? if possible to set a probing to aluminum to close the circuit?

I come from GRBL and March3. Normally i would do reset all then measure the z and -offset and start. On linuxcnc I have no idea how to reset all axis and set offset of workplace where my fixture is at.

I'm milling aluminum on APSX CNC and then I homed the cnc it goes back and home itself then i open gcode and move my cnc manually cnc axis to front to the aluminum spot and put it on corner of xy on left side of material then i hit start and it goes back to homed spot and start there when shouldnt be there.. How do i reset the xyz and set up my offset? if possible to set a probing to aluminum to close the circuit?

I come from GRBL and March3. Normally i would do reset all then measure the z and -offset and start. On linuxcnc I have no idea how to reset all axis and set offset of workplace where my fixture is at.

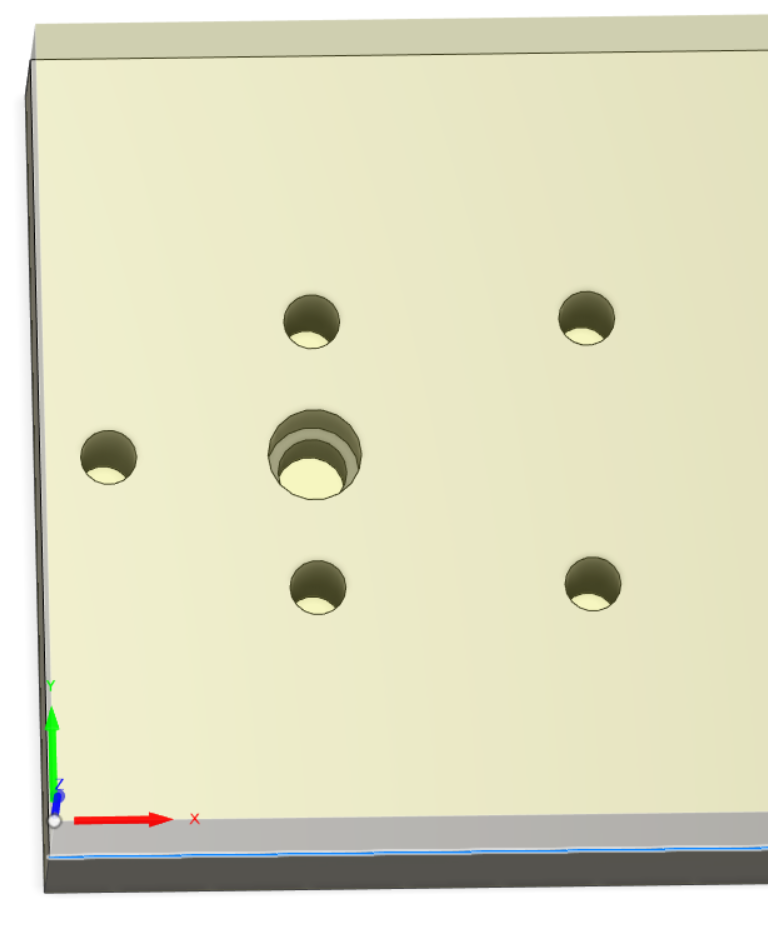

Attachments:

Last edit: 16 May 2022 19:40 by jsvalentin.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

16 May 2022 20:58 #243111

by robertspark

Replied by robertspark on topic Setting my workplace for milling

move to the location you want and type g92 x0 y0

linuxcnc.org/docs/html/gcode/g-code.html#gcode:g92

does this do what you want?

you can also use g54-g59 offsets too for repeated work using the same offsets.

linuxcnc.org/docs/html/gcode/g-code.html#gcode:g54-g59.3

linuxcnc.org/docs/html/gcode/g-code.html#gcode:g92

does this do what you want?

you can also use g54-g59 offsets too for repeated work using the same offsets.

linuxcnc.org/docs/html/gcode/g-code.html#gcode:g54-g59.3

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

17 May 2022 15:46 #243174

by andypugh

Replied by andypugh on topic Setting my workplace for milling

I wouldn't use G92.

Instead, move the tool to the position of your G-code origin (in this case front left corner) then press the "touch off" button in the GUI to set X = 0 Y = 0.

Then do the same with Z For Z I tend to move the tool to about 5mm away from the work, lay a 6mm broken endmill alongside the gap and then jog _up_ until the shank slips through the gap. Then touch-off Z as 6mm.

Instead, move the tool to the position of your G-code origin (in this case front left corner) then press the "touch off" button in the GUI to set X = 0 Y = 0.

Then do the same with Z For Z I tend to move the tool to about 5mm away from the work, lay a 6mm broken endmill alongside the gap and then jog _up_ until the shank slips through the gap. Then touch-off Z as 6mm.

Please Log in or Create an account to join the conversation.

- elf

- Offline

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 14

17 May 2022 18:19 #243187

by elf

Replied by elf on topic Setting my workplace for milling

That sounds safer than moving Z down until it touches a piece of paper.

Please Log in or Create an account to join the conversation.

Time to create page: 0.077 seconds