Machine stall after tool length probing

- d2inventory

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 10

21 Sep 2022 12:25 #252501

by d2inventory

Machine stall after tool length probing was created by d2inventory

Hi everyone

Sometimes the machine stalls when probing the tool length. Usually at the start of a program which is good so I can just rerun everything and it will be fine. But I kinda wanna know why this happens so I can trust the machine again

This is what I do:

Use MDI (or ngc program) to issue an "T1 M6" command

This calls the tool length measuring macro "messen.ngc"

I added some debug lines to see where exactly the program stalls.

1, 2, 3 -> stall

So the machine is stuck @ line 34 "G1 Z2.5 F500 (frei fahren)"

What is confusing me is when I check the machine status

It tells me the command is: "G38.2 Z-10 F25 (messen fein)"

But the debug message "4" never shows which is before that command.

Also the status shows "current_line 34" which would be a different command (the one above).

Could it be that the probe is jumpy and that is cancelling line 34?

Is there a way can see if it stalled because of a bouncy probe?

(I'm using debouncing in hal already with a value of 3)

Sometimes the machine stalls when probing the tool length. Usually at the start of a program which is good so I can just rerun everything and it will be fine. But I kinda wanna know why this happens so I can trust the machine again

This is what I do:

Use MDI (or ngc program) to issue an "T1 M6" command

This calls the tool length measuring macro "messen.ngc"

I added some debug lines to see where exactly the program stalls.

1, 2, 3 -> stall

So the machine is stuck @ line 34 "G1 Z2.5 F500 (frei fahren)"

What is confusing me is when I check the machine status

It tells me the command is: "G38.2 Z-10 F25 (messen fein)"

But the debug message "4" never shows which is before that command.

Also the status shows "current_line 34" which would be a different command (the one above).

Could it be that the probe is jumpy and that is cancelling line 34?

Is there a way can see if it stalled because of a bouncy probe?

(I'm using debouncing in hal already with a value of 3)

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

01 Oct 2022 16:37 #253188

by andypugh

Replied by andypugh on topic Machine stall after tool length probing

It's intriguing to read the rest of the output. It looks like execution is actually stalled at

And the reason that you see the numbers is:

To find where the system _really_ is you could try using an M67 command and watch the output with a halmeter.

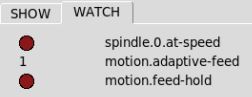

Though that doesn't really explain why the code should stall at the probe move. Is it possible that spindle-at speed is false, or feed-hold or adaptive feed are set to zero?

motion_line 30And the reason that you see the numbers is:

read_line 36To find where the system _really_ is you could try using an M67 command and watch the output with a halmeter.

Though that doesn't really explain why the code should stall at the probe move. Is it possible that spindle-at speed is false, or feed-hold or adaptive feed are set to zero?

Please Log in or Create an account to join the conversation.

- Boaschti

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

26 Feb 2023 20:22 #265436

by Boaschti

Replied by Boaschti on topic Machine stall after tool length probing

Hi,

I have the same problem with the same file (except positions).

I could create a minimal example to reproduce this behavior. My code stuck in line 21 exactly when probe is touched.

see here: .

I will check your listed pins. spindle-at-speed is definitly low.

I have the same problem with the same file (except positions).

I could create a minimal example to reproduce this behavior. My code stuck in line 21 exactly when probe is touched.

see here: .

I will check your listed pins. spindle-at-speed is definitly low.

Attachments:

Please Log in or Create an account to join the conversation.

- Boaschti

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

02 Mar 2023 16:15 #265725

by Boaschti

Replied by Boaschti on topic Machine stall after tool length probing

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

03 Mar 2023 15:02 #265781

by andypugh

Replied by andypugh on topic Machine stall after tool length probing

LinuxCNC will wait at any feed move (G1, G2, G3) if spindle.0.at-speed is false (as it is here. Slightly confusingly Halshow has dark red for false and yellow for true)

It is usual for spindle.0.at-speed to be driven true if the spindle speed is zero (and commanded to be zero) so you need to look at the HAL logic driving that pin.

It is usual for spindle.0.at-speed to be driven true if the spindle speed is zero (and commanded to be zero) so you need to look at the HAL logic driving that pin.

Please Log in or Create an account to join the conversation.

- Boaschti

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

03 Mar 2023 17:31 #265787

by Boaschti

Replied by Boaschti on topic Machine stall after tool length probing

I set the spindle-at-speed 5 seconds after spindle relay is set.

And I reset the spindle-at-speed when spindle relay is not set.

LinuxCNC waits these 5s if there is a G0, G1 after M3, that is correct.

Does it make sense, setting spindle-at-speed in probing mode although spindle is not running? During probing the spindle must not run.

Why the first G38.2 in my test file are working? spindle-at-speed is here also false.

And I reset the spindle-at-speed when spindle relay is not set.

LinuxCNC waits these 5s if there is a G0, G1 after M3, that is correct.

Does it make sense, setting spindle-at-speed in probing mode although spindle is not running? During probing the spindle must not run.

Why the first G38.2 in my test file are working? spindle-at-speed is here also false.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

03 Mar 2023 17:50 #265790

by andypugh

Replied by andypugh on topic Machine stall after tool length probing

Yes, because you generally want to prevent moves if the spindle has been stopped but is still spinning.

I don't think that spindle-at-speed blocks G38.x moves (though I think it probably should). So I would guess that your code is stopping at the first G1.

You do have the option of setting at-speed permanently true if you don't actually have any spindle speed feedback.

But, otherwise, if you are using a timer, then it should be true 5s after spindle on and 5s (or maybe more) after off.

I don't think that spindle-at-speed blocks G38.x moves (though I think it probably should). So I would guess that your code is stopping at the first G1.

You do have the option of setting at-speed permanently true if you don't actually have any spindle speed feedback.

But, otherwise, if you are using a timer, then it should be true 5s after spindle on and 5s (or maybe more) after off.

Please Log in or Create an account to join the conversation.

- Boaschti

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

03 Mar 2023 18:02 #265792

by Boaschti

Replied by Boaschti on topic Machine stall after tool length probing

I tested following file:

I wanted to test a G1 after a M3 command to force a wait for spindle-at-speed.

LinuxCNC stuck in Line 16.

Very strange.

I wanted to test a G1 after a M3 command to force a wait for spindle-at-speed.

LinuxCNC stuck in Line 16.

Very strange.

Attachments:

Please Log in or Create an account to join the conversation.

- Boaschti

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

03 Mar 2023 18:27 #265797

by Boaschti

Replied by Boaschti on topic Machine stall after tool length probing

Hm ok.

I need the feature that LCNC waits 5s until spindle relay switched on because the spindle has a external lock to prevent my fingers...

So how I have to configure it?

actual config:

relay-rrk-feedback => ladder timer TON 5s => spindle-at-speed

is this a solution:

on rising edge spindle.0.forward then reset ladder timer and spindle-at-speed then wait 5s and set spindle-at-speed

in hope that ther is no race condition.

But general I don't understand: If a M5 command was fired, why lcnc want to wait everywhere?

I need the feature that LCNC waits 5s until spindle relay switched on because the spindle has a external lock to prevent my fingers...

So how I have to configure it?

actual config:

relay-rrk-feedback => ladder timer TON 5s => spindle-at-speed

is this a solution:

on rising edge spindle.0.forward then reset ladder timer and spindle-at-speed then wait 5s and set spindle-at-speed

in hope that ther is no race condition.

But general I don't understand: If a M5 command was fired, why lcnc want to wait everywhere?

Please Log in or Create an account to join the conversation.

- Boaschti

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

04 Mar 2023 10:14 #265831

by Boaschti

Replied by Boaschti on topic Machine stall after tool length probing

test_tasten.ngc works with G0 instead of G1.

Please Log in or Create an account to join the conversation.

Time to create page: 0.103 seconds