- LinuxCNC

- General LinuxCNC Questions

- second hand cnc from 2007,could use help with pwm on odd control board

second hand cnc from 2007,could use help with pwm on odd control board

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

30 Nov 2022 01:40 #258071

by andypugh

Replied by andypugh on topic second hand cnc from 2007,could use help with pwm on odd control board

Here is a scematic for a very simple PWM to analogue voltage converter:

photos.app.goo.gl/zJHhpLkKZhAbrfV87

I designed that, and used it, about 10 years ago. Nowadays you can probably get one from Amazon.

Here is one of many (not a recommendation, just the first one I found)

www.amazon.com/dp/B07BDK8QDG

photos.app.goo.gl/zJHhpLkKZhAbrfV87

I designed that, and used it, about 10 years ago. Nowadays you can probably get one from Amazon.

Here is one of many (not a recommendation, just the first one I found)

www.amazon.com/dp/B07BDK8QDG

The following user(s) said Thank You: beau

Please Log in or Create an account to join the conversation.

- beau

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Nov 2022 01:40 #258072

by beau

Replied by beau on topic second hand cnc from 2007,could use help with pwm on odd control board

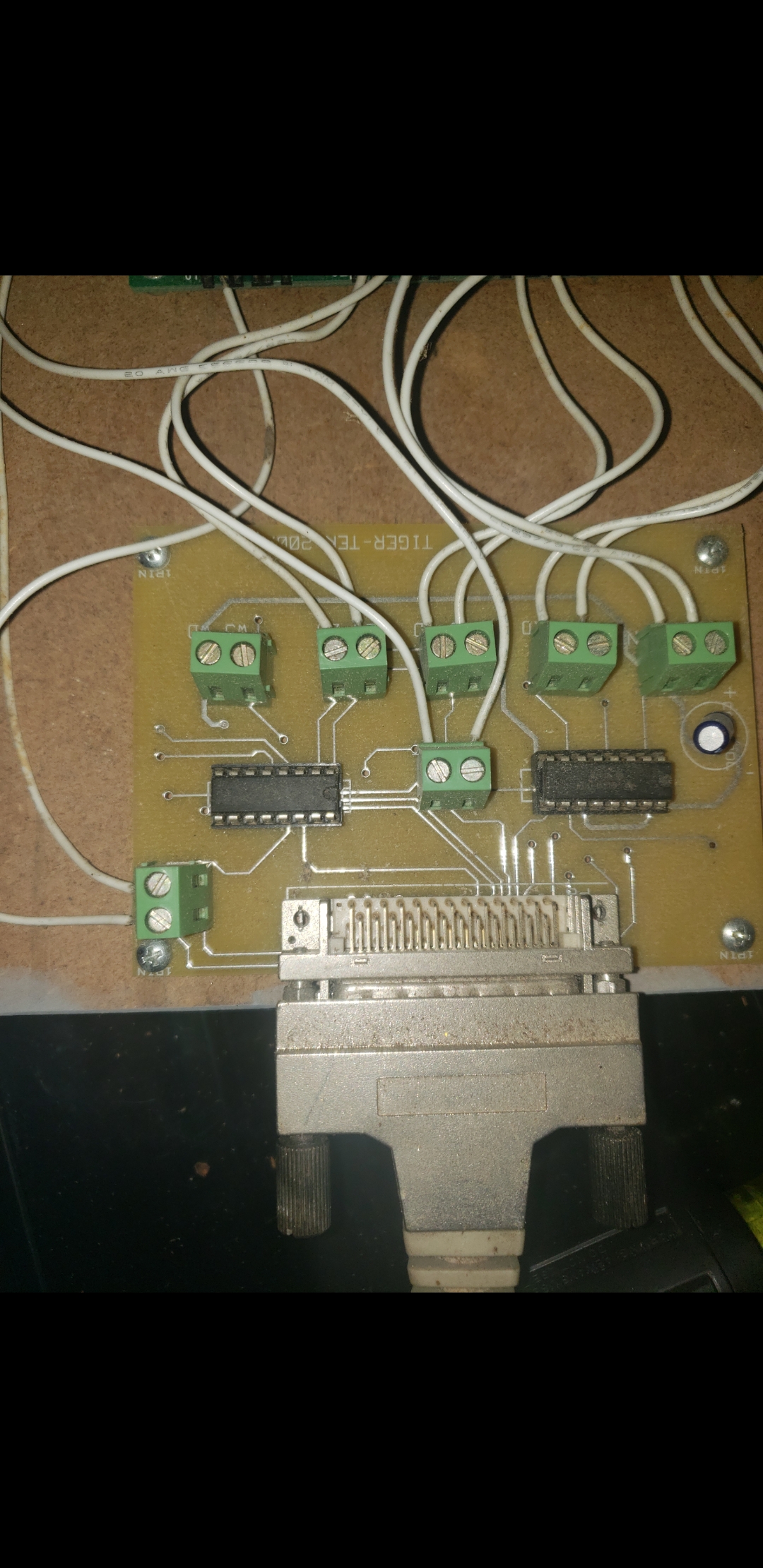

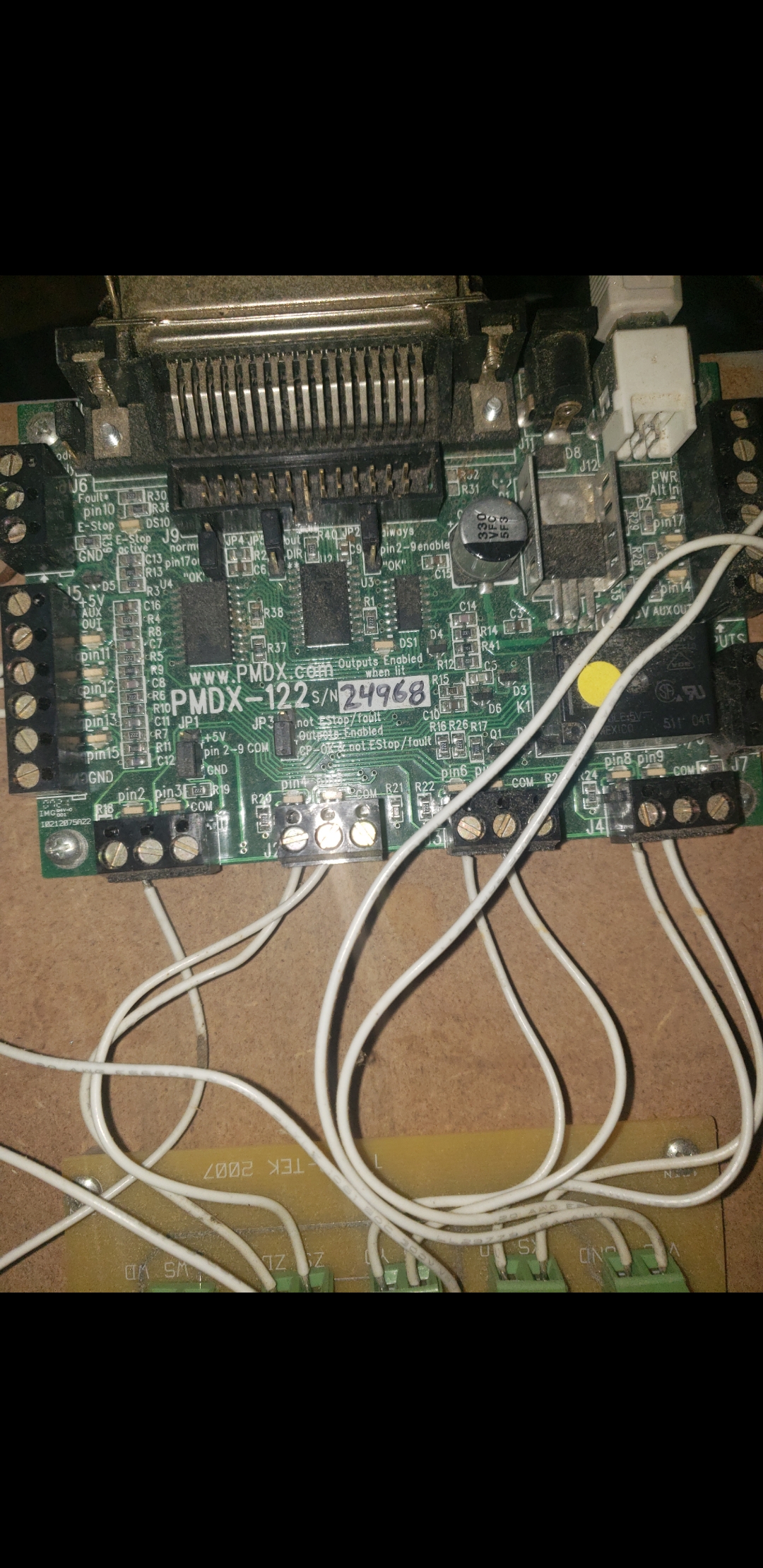

some pics of boards

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21053

- Thank you received: 7181

30 Nov 2022 01:44 #258073

by tommylight

Replied by tommylight on topic second hand cnc from 2007,could use help with pwm on odd control board

No pictures!

Please Log in or Create an account to join the conversation.

- beau

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Nov 2022 01:47 #258074

by beau

Replied by beau on topic second hand cnc from 2007,could use help with pwm on odd control board

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

30 Nov 2022 01:52 #258075

by andypugh

Replied by andypugh on topic second hand cnc from 2007,could use help with pwm on odd control board

I would hazard a guess that the beige board is just a couple of ULN2003 chips?

Please Log in or Create an account to join the conversation.

- spumco

- Away

- Platinum Member

-

Less

More

- Posts: 1961

- Thank you received: 798

30 Nov 2022 02:30 #258078

by spumco

Replied by spumco on topic second hand cnc from 2007,could use help with pwm on odd control board

Please Log in or Create an account to join the conversation.

- beau

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Nov 2022 02:31 #258079

by beau

Replied by beau on topic second hand cnc from 2007,could use help with pwm on odd control board

thanks everyone for all the input and offering your time and expertise. very warm welcome to a newbie. ill dig in with the base I have gotten and see what success I may have.

and as for the board just cheap insurance against emf? or open circuit failure between the drivers and pc?

I could just buy a little adapter and go with that but id like to try and get my head around hal and some of what linuxcnc has to offer if nothing else but to learn a little something if possible.

again thanks to everyone who has chimed in much appreciated id hate to waste your time too much without trying to apply some of what has been suggested so far and put some effort in before asking much more of you guys.

and as for the board just cheap insurance against emf? or open circuit failure between the drivers and pc?

I could just buy a little adapter and go with that but id like to try and get my head around hal and some of what linuxcnc has to offer if nothing else but to learn a little something if possible.

again thanks to everyone who has chimed in much appreciated id hate to waste your time too much without trying to apply some of what has been suggested so far and put some effort in before asking much more of you guys.

Please Log in or Create an account to join the conversation.

- beau

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Nov 2022 02:40 #258080

by beau

Replied by beau on topic second hand cnc from 2007,could use help with pwm on odd control board

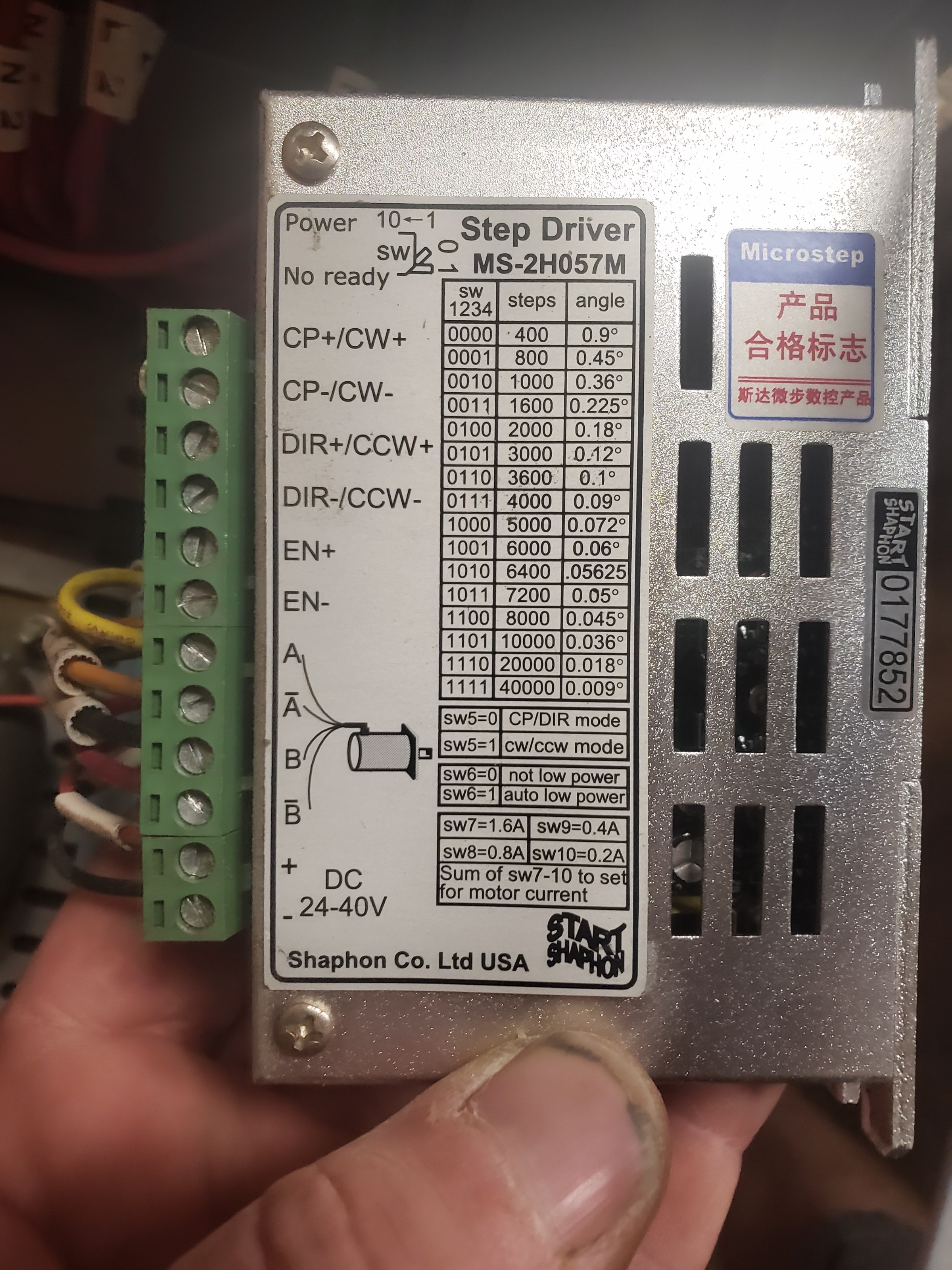

it has drives for each axis ive been wondering why the redundancy of so many boards i assumed that the lower board was doing the step dir and thats why I had gotten good speeds with not great latency. I've seen setups with the pmdx alone and the though crossed my mind that I had someone's half solution to a dsp control changed over to a mach3 control. its doing ok so far .ill learn what I like what I dont, and ill have something to base my changes and my purchases off of when I get to that point. its really my starting point in cnc other than just operating one.

its been ridiculous finding info on a build like this tho cause not only is every part outdated. but it seems the sum of the parts were bandaids and reworked more than planned and thought out. but I dont really have enough knowledge to make statements like that.

its been ridiculous finding info on a build like this tho cause not only is every part outdated. but it seems the sum of the parts were bandaids and reworked more than planned and thought out. but I dont really have enough knowledge to make statements like that.

Attachments:

Please Log in or Create an account to join the conversation.

- spumco

- Away

- Platinum Member

-

Less

More

- Posts: 1961

- Thank you received: 798

30 Nov 2022 03:25 #258084

by spumco

Replied by spumco on topic second hand cnc from 2007,could use help with pwm on odd control board

The PC (LCNC) is doing step & direction outputs

The PMDX is all you need. It's quite possible - likely even - that the PMDX was added later for some reason.

PMDX is a US-based company making pretty high-quality components. Weird pin naming, confusing user manuals, and they're locked in to Mach4...but high-quality stuff. The fact that they used 2mhz optocouplers 15 years ago speaks volumes.

Not the kind of thing a low-cost overseas OEM would use... but exactly the sort of thing some owner would put in after the fact. And remember - as old as that router is, there weren't a ton of options in the mid 2000's for hobby-ish breakout boards and motion control.

So you've got drives. Just hook the PMDX up to the PC, the drives to the PMDX, and you're in business. Like starting from scratch, but free.

The PMDX is all you need. It's quite possible - likely even - that the PMDX was added later for some reason.

PMDX is a US-based company making pretty high-quality components. Weird pin naming, confusing user manuals, and they're locked in to Mach4...but high-quality stuff. The fact that they used 2mhz optocouplers 15 years ago speaks volumes.

Not the kind of thing a low-cost overseas OEM would use... but exactly the sort of thing some owner would put in after the fact. And remember - as old as that router is, there weren't a ton of options in the mid 2000's for hobby-ish breakout boards and motion control.

So you've got drives. Just hook the PMDX up to the PC, the drives to the PMDX, and you're in business. Like starting from scratch, but free.

Please Log in or Create an account to join the conversation.

- beau

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Nov 2022 04:11 #258089

by beau

Replied by beau on topic second hand cnc from 2007,could use help with pwm on odd control board

I am guilty of misuse of terms often i know. but im of the understanding that the steps and direction come from linuxcnc but I was under the impression that the control board was doing the heavy lifting and making the pulses and that was how I was running decent with 30,000/ 35000 latency numbers. I was told and have read that the mesa cards do the same thing only at a multiple of like 50 or more than the hardware im running.

if im way off base please by all means correct me. I was aware I could run just the pmdx 122. but was under the impression that my control board was a benefit ( however outdated) .

your saying that I can lose the two other boards and im not gonna suffer any loses for it?

I wondered why the redundancy and assumed the pmdx 122 was simply better suited to replace the dsp handle and the loading of g code from a USB stick with a pc and mach3 . and thats where the concept that the lower control board was doing the heavy lifting came from was the fact that it used to do everything except translate the gcode and send the signals ,which the dsp handset did.

im new to all of this and maybe im guilty of too many assumptions, I get the concept of running on the pmdx alone but your saying I can do so without taking a hit on speed and latency? preforming the same ?

possibly an improvement maybe?

if im way off base please by all means correct me. I was aware I could run just the pmdx 122. but was under the impression that my control board was a benefit ( however outdated) .

your saying that I can lose the two other boards and im not gonna suffer any loses for it?

I wondered why the redundancy and assumed the pmdx 122 was simply better suited to replace the dsp handle and the loading of g code from a USB stick with a pc and mach3 . and thats where the concept that the lower control board was doing the heavy lifting came from was the fact that it used to do everything except translate the gcode and send the signals ,which the dsp handset did.

im new to all of this and maybe im guilty of too many assumptions, I get the concept of running on the pmdx alone but your saying I can do so without taking a hit on speed and latency? preforming the same ?

possibly an improvement maybe?

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- second hand cnc from 2007,could use help with pwm on odd control board

Time to create page: 0.244 seconds