Change default set-up home from 0,0,1 to 0,0,0.25

- jferguson

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

16 Feb 2023 19:42 #264640

by jferguson

Change default set-up home from 0,0,1 to 0,0,0.25 was created by jferguson

When I fire up Linuxcnc to run the mill, after I've engaged the E-Switch and the second switch I must home each axis before starting the run. LinuxCNC then sets the home to 0,0,1.0. The height gage I use is 1/4 inch in thickness (for a good reason). I now have to do some manual fussing to get what I want.

How can I change this default to X=0, Y=0, and Z=0.250?

How can I change this default to X=0, Y=0, and Z=0.250?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21145

- Thank you received: 7221

17 Feb 2023 11:40 #264687

by tommylight

Replied by tommylight on topic Change default set-up home from 0,0,1 to 0,0,0.25

Edit the ini file in the config folder with the machine name, set

Home = 0 or whatever you need for each axis and joint

Home_offset = 0 or whatever you need after homing is finished.

Normaly Home is 0, while Home_offset is set to something small so the machine backs off of the limit switches, or if you need the machine to position itself somewhere else to easier load material.

Be aware that using Home_offset will show 0 after homing, and using Home values will show those values.

Home = 0 or whatever you need for each axis and joint

Home_offset = 0 or whatever you need after homing is finished.

Normaly Home is 0, while Home_offset is set to something small so the machine backs off of the limit switches, or if you need the machine to position itself somewhere else to easier load material.

Be aware that using Home_offset will show 0 after homing, and using Home values will show those values.

Please Log in or Create an account to join the conversation.

- jferguson

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

17 Feb 2023 16:11 - 17 Feb 2023 16:17 #264700

by jferguson

Replied by jferguson on topic Change default set-up home from 0,0,1 to 0,0,0.25

thanks much.

btw, My installation of a Debian 2.8.4 linuxcnc instance on my multi boot machine is a roaring success. 2tricks, one was to use ethernet (no driver for my wifi card in this Debioan ISO, if Grub loader refuses to install, use the one you already had.

john

btw, My installation of a Debian 2.8.4 linuxcnc instance on my multi boot machine is a roaring success. 2tricks, one was to use ethernet (no driver for my wifi card in this Debioan ISO, if Grub loader refuses to install, use the one you already had.

john

Last edit: 17 Feb 2023 16:17 by jferguson.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- jferguson

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

17 Feb 2023 17:45 - 17 Feb 2023 17:46 #264704

by jferguson

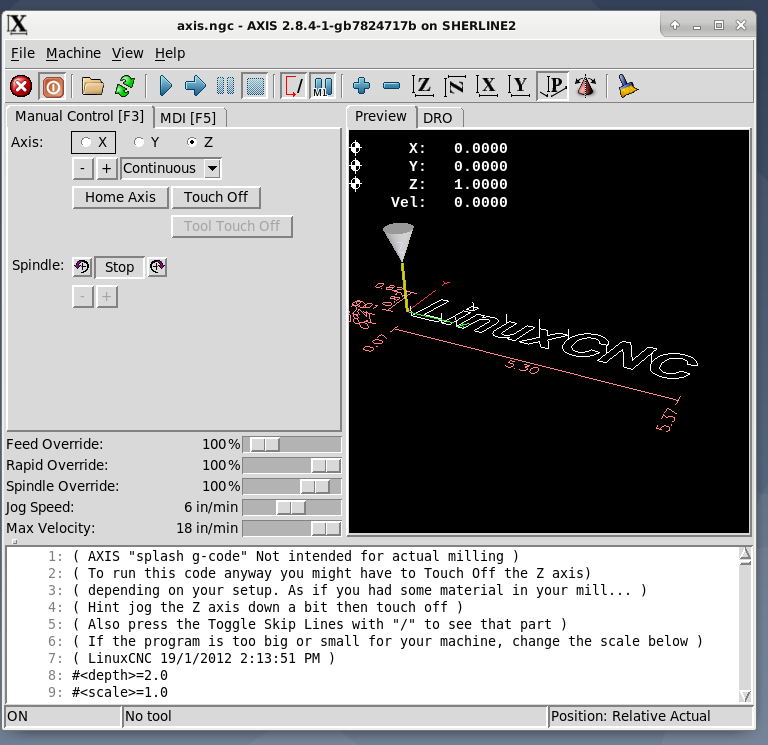

I was hoping that somehow, I could get the homing setup which is shown on this screen to indicate the Z Home to be .250. I just cannot find anywhere in the INI where this can be changed. Is it hard-coded somewhere?

I suppose an alternative way to get the result I want it is to put a line sending the machine to Z0.25 (instead of 1.0000) before the first stop for a tool change.

Replied by jferguson on topic Change default set-up home from 0,0,1 to 0,0,0.25

I was hoping that somehow, I could get the homing setup which is shown on this screen to indicate the Z Home to be .250. I just cannot find anywhere in the INI where this can be changed. Is it hard-coded somewhere?

I suppose an alternative way to get the result I want it is to put a line sending the machine to Z0.25 (instead of 1.0000) before the first stop for a tool change.

Attachments:

Last edit: 17 Feb 2023 17:46 by jferguson.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4624

- Thank you received: 2046

17 Feb 2023 17:53 - 17 Feb 2023 17:55 #264705

by Aciera

Replied by Aciera on topic Change default set-up home from 0,0,1 to 0,0,0.25

As already suggested:

Change the HOME_OFFSET value in the relevant JOINT_n section of the ini file (where 'n' is the joint number for your z axis)

linuxcnc.org/docs/html/config/ini-config.html#sec:joint-section

edit:

If unsure please post your ini file.

Change the HOME_OFFSET value in the relevant JOINT_n section of the ini file (where 'n' is the joint number for your z axis)

linuxcnc.org/docs/html/config/ini-config.html#sec:joint-section

edit:

If unsure please post your ini file.

Last edit: 17 Feb 2023 17:55 by Aciera.

Please Log in or Create an account to join the conversation.

- jferguson

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

17 Feb 2023 18:29 #264711

by jferguson

Replied by jferguson on topic Change default set-up home from 0,0,1 to 0,0,0.25

Worked exactly as I wanted. Thank you both so much for helping me with this.

John

John

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 262

- Thank you received: 51

17 Feb 2023 21:27 #264723

by pippin88

Replied by pippin88 on topic Change default set-up home from 0,0,1 to 0,0,0.25

The safest home position is with Z all the way up.

If the 0.25 is just for a tool change, think hard about all possible machine movement scenarios.

E.g clamps, workholding, tall work piece.

You don't want some g code to tell the machine to go to home (e.g. G53 X0Y0Z0) and smash into clamps etc.

The most common way to setup a machine is for Z0 to be at the top of the Z travel, and for all Z travel to be negative.

If you are not already familiar with the difference between

G53 / machine coordinates

G54-G59 / work coordinates

Then I suggest you read about them as it's very important to understand

If the 0.25 is just for a tool change, think hard about all possible machine movement scenarios.

E.g clamps, workholding, tall work piece.

You don't want some g code to tell the machine to go to home (e.g. G53 X0Y0Z0) and smash into clamps etc.

The most common way to setup a machine is for Z0 to be at the top of the Z travel, and for all Z travel to be negative.

If you are not already familiar with the difference between

G53 / machine coordinates

G54-G59 / work coordinates

Then I suggest you read about them as it's very important to understand

The following user(s) said Thank You: jferguson

Please Log in or Create an account to join the conversation.

- jferguson

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

18 Feb 2023 00:02 #264728

by jferguson

Replied by jferguson on topic Change default set-up home from 0,0,1 to 0,0,0.25

hi Pippin, I do tiny stuff on a Sherline 2000 with very small bits. I've found the best way to set the height is to roll a piece of .250 drill rod back and forth under the bit until the bit just clears. If I set Z to .250, All I need to do is start linuxcnc, home all axes and then turn everything on. It may seem clunky, but this is not a production environment and I can take the time needed to not destroy bits and gouge workpieces.

I picked up this method routing PCB;s where the depth of cut is critical.

I picked up this method routing PCB;s where the depth of cut is critical.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11600

- Thank you received: 3900

18 Feb 2023 08:58 #264742

by rodw

Replied by rodw on topic Change default set-up home from 0,0,1 to 0,0,0.25

you can still home at top of travel but use g54 offsets and touch off the Z axis to 0.0 at the height you want.

The following user(s) said Thank You: jferguson

Please Log in or Create an account to join the conversation.

Time to create page: 0.103 seconds