Spindle encoder with one intiator but 4 pulses per revolution

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

02 Apr 2023 19:55 #268103

by fletch

Spindle encoder with one intiator but 4 pulses per revolution was created by fletch

This is a follow on from @Sviper's post: forum.linuxcnc.org/38-general-linuxcnc-q...e-emulate-an-encoder which I was hoping I could use directly. But on dismantling the sensor on my mill it turns out to be a photo interruptor with four 'windows' per revolution. I suspect this is a fairly common implementation on the import mills.

I haven't yet tried to implement the above post as I'm waiting for the hardware to arrive (I'll be running two photo interrupters - one for the mill's 'vfd' display and new one for the 7i96 to consume so I can compare the numbers) but I'm if I'm reading it correctly, I'll be reporting 4x the rpm.

Is there a way to apply a 'divide by 4' in the hal config?

I haven't yet tried to implement the above post as I'm waiting for the hardware to arrive (I'll be running two photo interrupters - one for the mill's 'vfd' display and new one for the 7i96 to consume so I can compare the numbers) but I'm if I'm reading it correctly, I'll be reporting 4x the rpm.

Is there a way to apply a 'divide by 4' in the hal config?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21049

- Thank you received: 7181

02 Apr 2023 21:38 #268118

by tommylight

Replied by tommylight on topic Spindle encoder with one intiator but 4 pulses per revolution

linuxcnc.org/docs/html/man/man9/encoder.9.html

See under PINS

encoder.N.counter-mode

and

encoder.N.x4-mode

See under PINS

encoder.N.counter-mode

and

encoder.N.x4-mode

The following user(s) said Thank You: fletch

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

02 Apr 2023 22:50 - 02 Apr 2023 23:03 #268126

by fletch

Replied by fletch on topic Spindle encoder with one intiator but 4 pulses per revolution

Thank you Tommy - in the Sviper post, Andy Pugh replies saying to set counter-mode to 1 which according to the docs would mean x4-mode will be ignored.

I think perhaps I may have asked the wrong question - all encoders 'pulse' multiple times per revolution, so the question I should be asking is where do I set the encoder resolution for the spindle?

Edit: Now that I've thought about the question, position-scale seems like a suitable candidate?

I think perhaps I may have asked the wrong question - all encoders 'pulse' multiple times per revolution, so the question I should be asking is where do I set the encoder resolution for the spindle?

Edit: Now that I've thought about the question, position-scale seems like a suitable candidate?

Last edit: 02 Apr 2023 23:03 by fletch. Reason: Refined my google-foo by asking the wrong question

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21049

- Thank you received: 7181

03 Apr 2023 01:16 #268136

by tommylight

Replied by tommylight on topic Spindle encoder with one intiator but 4 pulses per revolution

In the hal file, there should be a whole section about spindle feedback, there should be encoder-scaleIn this case the encoder scale is set in the ini file and read from there.

This is from an old retrofit, so use with caution.

# ---Encoder feedback signals/setup---

setp hm2_7i92.0.encoder.05.counter-mode 0

setp hm2_7i92.0.encoder.05.filter 1

setp hm2_7i92.0.encoder.05.index-invert 0

setp hm2_7i92.0.encoder.05.index-mask 0

setp hm2_7i92.0.encoder.05.index-mask-invert 0

setp hm2_7i92.0.encoder.05.scale [SPINDLE_9]ENCODER_SCALE

net spindle-revs <= hm2_7i92.0.encoder.05.position

net spindle-vel-fb-rps <= hm2_7i92.0.encoder.05.velocity

net spindle-index-enable <=> hm2_7i92.0.encoder.05.index-enableThis is from an old retrofit, so use with caution.

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

03 Apr 2023 08:57 #268155

by fletch

Replied by fletch on topic Spindle encoder with one intiator but 4 pulses per revolution

Aha! Thank you. I think I'd searched my .hal file for 'encoder' before actually assigning 'Spindle' to the 'Quad Enc-A/B/I' inputs - Doh!

I will be able to test as soon as the parts arrive (and I summon my inner Binky to make a custom bracket)...

I will be able to test as soon as the parts arrive (and I summon my inner Binky to make a custom bracket)...

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

20 Apr 2023 16:24 - 20 Apr 2023 16:26 #269491

by fletch

Replied by fletch on topic Spindle encoder with one intiator but 4 pulses per revolution

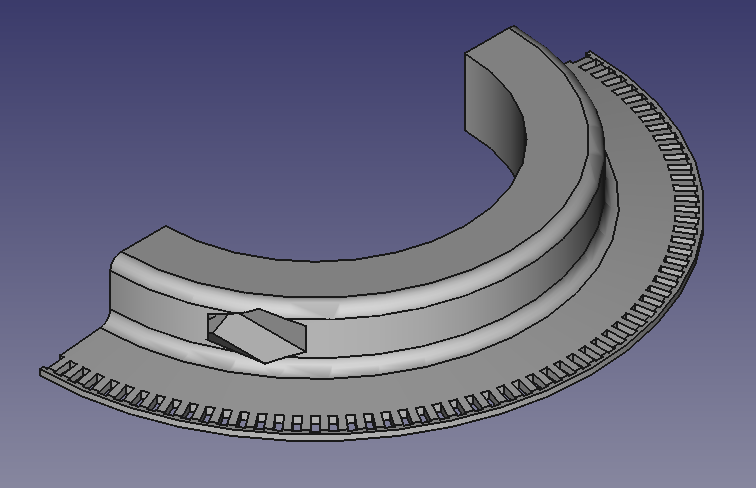

You know I can't leave this alone, don't you? So I've started designing a quadrature encoder+index that I can strap to the spindle inside the mill head (where the current single pulse encoder is):

This is currently designed with 128 'windows' which if I understand quadrature correctly and set the two readers x.5 windows apart I should get 512 position 'indications' per revolution - rigid tapping FTW?

I've tested 3D printing up to 250 windows but I'm not sure the opto switches I've ordered (EE-SX1025, 0.5mm window) will read that resolution reliably..

On the Mesa 7i96 card, I have the option of single ended or differential mode - initially for testing I'll use single ended mode as is currently working for four 'windows' non-quadrature, but was wondering about the value of trying to implement differential mode and what that circuit/electronics would look like? Probably not the right place to ask, but everyone on here seems much smarter than me...

This is currently designed with 128 'windows' which if I understand quadrature correctly and set the two readers x.5 windows apart I should get 512 position 'indications' per revolution - rigid tapping FTW?

I've tested 3D printing up to 250 windows but I'm not sure the opto switches I've ordered (EE-SX1025, 0.5mm window) will read that resolution reliably..

On the Mesa 7i96 card, I have the option of single ended or differential mode - initially for testing I'll use single ended mode as is currently working for four 'windows' non-quadrature, but was wondering about the value of trying to implement differential mode and what that circuit/electronics would look like? Probably not the right place to ask, but everyone on here seems much smarter than me...

Attachments:

Last edit: 20 Apr 2023 16:26 by fletch. Reason: Randon image resizing strings in the test.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17477

- Thank you received: 5106

20 Apr 2023 17:39 - 20 Apr 2023 17:40 #269496

by PCW

Replied by PCW on topic Spindle encoder with one intiator but 4 pulses per revolution

To convert single ended to differential, you typically use a

differential driver chip like a 26ls31 or equivalent.

You can use lower resolution opto devices by using a Moire mask

(as most high resolution encoders use)

This mask is just a sector of your disk with the same pitch slots

but 2 sections with the slots in the second section having a 1/4

pitch (1/2 slot width) offset from the first section.

These allow large area light source and sensors.

differential driver chip like a 26ls31 or equivalent.

You can use lower resolution opto devices by using a Moire mask

(as most high resolution encoders use)

This mask is just a sector of your disk with the same pitch slots

but 2 sections with the slots in the second section having a 1/4

pitch (1/2 slot width) offset from the first section.

These allow large area light source and sensors.

Last edit: 20 Apr 2023 17:40 by PCW.

The following user(s) said Thank You: fletch

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

20 Apr 2023 18:33 #269498

by fletch

Replied by fletch on topic Spindle encoder with one intiator but 4 pulses per revolution

Brilliant! Thank you. The

26LS31

is something I shall have to investigate - a bit above my pay grade, but I'm sure I can learn...

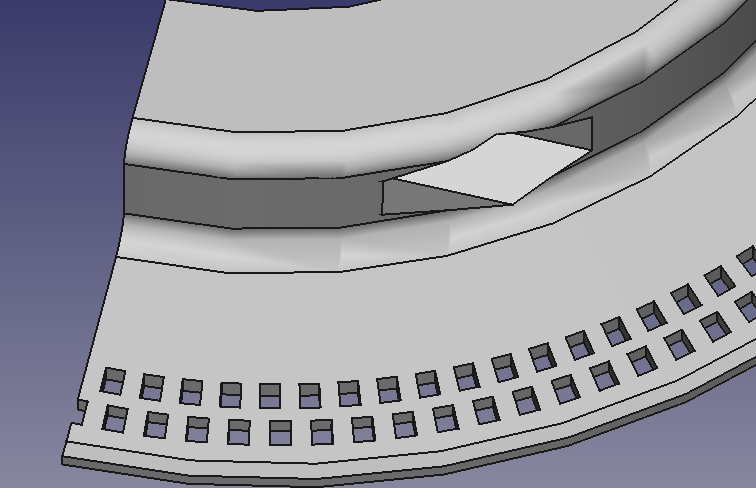

I thought this is what you mean by Moire:

with each opto switch reading a different 'track', but now I'm thinking I've got it wrong because I can't see the difference between what I've drawn and just offsetting the two opto switches by half a slot?

I found this industrytoday.com/encoder-performance/ but they are showing an led+mask+photodiodes - the EE-SX1025 I'll be using already has a 0.5mm 'mask'. I suspect much experimentation is needed - I'm only going to 4,000rpm - the only question is, can I get the resolution good enough for rigid tapping...

I thought this is what you mean by Moire:

with each opto switch reading a different 'track', but now I'm thinking I've got it wrong because I can't see the difference between what I've drawn and just offsetting the two opto switches by half a slot?

I found this industrytoday.com/encoder-performance/ but they are showing an led+mask+photodiodes - the EE-SX1025 I'll be using already has a 0.5mm 'mask'. I suspect much experimentation is needed - I'm only going to 4,000rpm - the only question is, can I get the resolution good enough for rigid tapping...

Attachments:

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

20 Apr 2023 18:43 - 20 Apr 2023 18:44 #269501

by fletch

Replied by fletch on topic Spindle encoder with one intiator but 4 pulses per revolution

I think I've got my head around the moire mask now - if I was using a opto receiver & separate light source it would be the right thing but don't think it would make any difference to the

EE-SX1025

's 0.5mm receiving slot.

Last edit: 20 Apr 2023 18:44 by fletch.

Please Log in or Create an account to join the conversation.

Time to create page: 0.113 seconds