g76 problem

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 358

- Thank you received: 87

30 Apr 2023 19:53 #270331

by Masiwood123

g76 problem was created by Masiwood123

..after a long break, here I am again in the workshop. I'm trying to make a simple thread on the lathe. the control card is 7i96s. spindle motor is AC servo with own encoder. I did not connect an additional encoder to the card (the servo driver reads the correct revolutions from its own encoder). the question is, does the additional encoder have to be connected for the g76 to work, otherwise the g76 stays on that line and nothing happens? thanks

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20495

- Thank you received: 6975

30 Apr 2023 22:46 #270346

by tommylight

Replied by tommylight on topic g76 problem

Pretty sure it does require having encoder feedback to LinuxCNC, otherwise it has no clue what the spindle is doing.

For some stuff it require A or B and Index, for some it requires both A and B besides index.

Been several years, so forgot details.

Or getting old...

For some stuff it require A or B and Index, for some it requires both A and B besides index.

Been several years, so forgot details.

Or getting old...

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11311

- Thank you received: 3792

30 Apr 2023 23:04 #270348

by rodw

Replied by rodw on topic g76 problem

Some servo drives have encoder outputs to piggyback to the motion controller. Does yours?

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 18986

- Thank you received: 5242

30 Apr 2023 23:14 #270349

by PCW

Replied by PCW on topic g76 problem

If the drive has an encoder output, you need no additional encoder

but the drives encoder output must connect to the 7I96S and it must

have a index signal.

I order for G76 to work you need:

Spindle encoder scaling and direction right

Spindle at speed true

Index working properly

but the drives encoder output must connect to the 7I96S and it must

have a index signal.

I order for G76 to work you need:

Spindle encoder scaling and direction right

Spindle at speed true

Index working properly

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 358

- Thank you received: 87

30 Apr 2023 23:43 #270352

by Masiwood123

Replied by Masiwood123 on topic g76 problem

thank you very much, i understood, i just didn't see at first that my driver has encoder outputs... will try tomorrow to connect them to the card, since I don't know how to change the hal/ini, I'll try to make a new configuration through pncconf including the encoder. I will let you know..

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 358

- Thank you received: 87

01 May 2023 20:47 - 01 May 2023 20:51 #270427

by Masiwood123

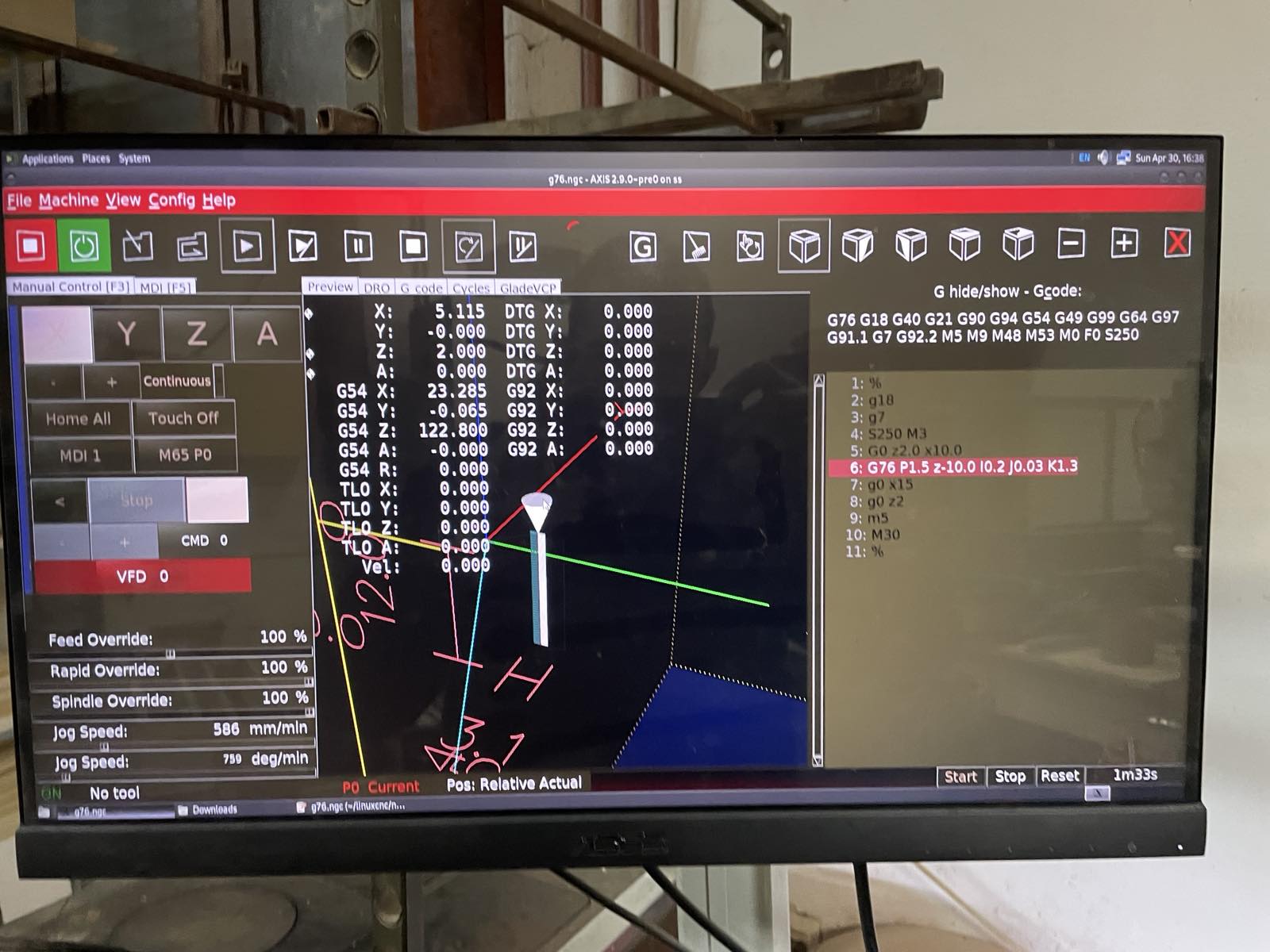

friends, I connected it and it works:) I'm not satisfied with the thread, I'll check it on metal, it won't work on wood(m10 is not m10). I still need to understand whether 1-5rpm +- is so important or does the controller itself take feed parameters based on rpm feedback? m4 also doesn't work for me (that is, it works in the same direction as m3), do I have to control the change of direction of m4 via the relay on the driver input or should I try via the card by using negative voltage? the driver is AASD 2.3kw. Thank you very much for your help.

G76 P1.5 I-0.2 J0.03 K1.4(for m10?)

Replied by Masiwood123 on topic g76 problem

friends, I connected it and it works:) I'm not satisfied with the thread, I'll check it on metal, it won't work on wood(m10 is not m10). I still need to understand whether 1-5rpm +- is so important or does the controller itself take feed parameters based on rpm feedback? m4 also doesn't work for me (that is, it works in the same direction as m3), do I have to control the change of direction of m4 via the relay on the driver input or should I try via the card by using negative voltage? the driver is AASD 2.3kw. Thank you very much for your help.

G76 P1.5 I-0.2 J0.03 K1.4(for m10?)

Attachments:

Last edit: 01 May 2023 20:51 by Masiwood123.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 358

- Thank you received: 87

01 May 2023 20:48 #270428

by Masiwood123

Replied by Masiwood123 on topic g76 problem

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2246

- Thank you received: 482

02 May 2023 16:19 #270491

by Clive S

Replied by Clive S on topic g76 problem

This works for me:

G0 G40 G18 G80 G21 G49 G95

G90 G7

F300 S450

M3

G4 P1

M7

G0 X10 Z2

G76 P1.5 Z-30 I-.1 J0.1 R 1 K3 Q29.5 L3 E0.5 H2

g0 X20

g0 Z10

M9

M5

M2

%

G0 G40 G18 G80 G21 G49 G95

G90 G7

F300 S450

M3

G4 P1

M7

G0 X10 Z2

G76 P1.5 Z-30 I-.1 J0.1 R 1 K3 Q29.5 L3 E0.5 H2

g0 X20

g0 Z10

M9

M5

M2

%

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 358

- Thank you received: 87

02 May 2023 18:08 #270499

by Masiwood123

Replied by Masiwood123 on topic g76 problem

i can try thank you.I see now that I didn't use G95:)... J is too much for my lathe 0.03 pass is ok. the only thing I can't understand is why K3 (thread depth) .. I think it's some formula P x cos30 x 2?

Please Log in or Create an account to join the conversation.

Time to create page: 0.087 seconds