- LinuxCNC

- General LinuxCNC Questions

- What would be the easiest way to get super accurate homing (milling machine)?

What would be the easiest way to get super accurate homing (milling machine)?

- Markgonz

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

29 Jun 2023 23:20 #274477

by Markgonz

What would be the easiest way to get super accurate homing (milling machine)? was created by Markgonz

Hello friends of the linuxcnc community,

I am building a small accurate cnc mill now for micromachining, one thing that is important for me is accurate homing because my idea is to use a zero point system, in case some of you don't know what is it let me explain briefly, is a workholding solution really popular for production in industrial machines, the main body stays on the table and it can hold pallets about 50mmx50mm usually in brass or steel with a repeatability of about 2 microns, this is handy for micromachining because you can make fixtures where the parts for machining go for various operations.

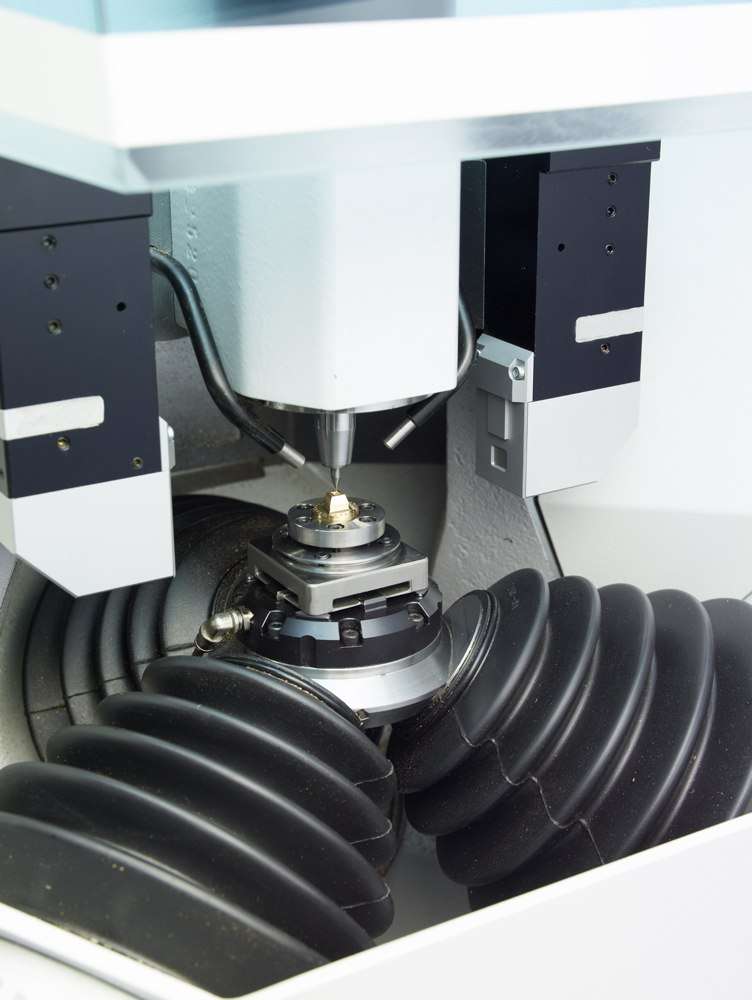

Here is a pic of an awesome Swiss made mill for micromachining with a zero point system:

I guess is important to say what means super accurate homing, so I guess is about 10 microns would be what I am looking for.

So my understanding for homing is that you can do it in several ways:

-rely on homing switches, inductive or mechanical,

-closed loop system and use a index pulse of the stepper or servo encoder so homing will be as good as the ballscrew can allow

-use glass scales and rely on the index pulse of a scale that is attached to the table and aligned with the axis, this is as good as the scale accuracy and alignment with the axis, so should be one of the best options but seems complicated.

-go with ethercat system and then no need for homing switches because the servos/steppers can keep track and remember homing digitally

- probing the zero point system everytime I turn on the machine to get center coordinates, this seems good option too but slow and in my case not posible because my mill will be really small with limited travel.

Really looking forward of hearing your thoughts on this, thanks in advance!

I am building a small accurate cnc mill now for micromachining, one thing that is important for me is accurate homing because my idea is to use a zero point system, in case some of you don't know what is it let me explain briefly, is a workholding solution really popular for production in industrial machines, the main body stays on the table and it can hold pallets about 50mmx50mm usually in brass or steel with a repeatability of about 2 microns, this is handy for micromachining because you can make fixtures where the parts for machining go for various operations.

Here is a pic of an awesome Swiss made mill for micromachining with a zero point system:

I guess is important to say what means super accurate homing, so I guess is about 10 microns would be what I am looking for.

So my understanding for homing is that you can do it in several ways:

-rely on homing switches, inductive or mechanical,

-closed loop system and use a index pulse of the stepper or servo encoder so homing will be as good as the ballscrew can allow

-use glass scales and rely on the index pulse of a scale that is attached to the table and aligned with the axis, this is as good as the scale accuracy and alignment with the axis, so should be one of the best options but seems complicated.

-go with ethercat system and then no need for homing switches because the servos/steppers can keep track and remember homing digitally

- probing the zero point system everytime I turn on the machine to get center coordinates, this seems good option too but slow and in my case not posible because my mill will be really small with limited travel.

Really looking forward of hearing your thoughts on this, thanks in advance!

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

30 Jun 2023 02:08 #274483

by spumco

Replied by spumco on topic What would be the easiest way to get super accurate homing (milling machine)?

You don't need really accurate homing to use a zero-point system. You'll be probing the zero-point fixture (like the Erowa shown) before machining - at least the first time for a run of parts.

If you don't plan on probing then how are you going to account for thermal growth - especially on the Z-axis (spindle heat)?

At the mechanical resolution you're discussing you need to take thermal growth in to account. That's done either through probing and/or mapping the machine movements using some serious instrumentation likely beyond the reach of most homegamers.

A good quality proximity sensor can get you within a few thousanths of a home position. Not too bad for a linear axis, but not really good enough for a rotary axis (error changes depending on distance from axis center).

Probing doesn't have to be slow. If you use a zero-point system you can preprogram a macro to probe the zero-point base (or a feature machined on all your pallets) and approach at rapid speed until just a few mm away. A 3-point double touch probe cycle shouldn't take more than 5-7 seconds (guess) at the start of the machining cycle. If you're worried about shaving 20 seconds off cycle time...

Back to your question... my inexpert opinion is that an Ethercat system with absolute encoders and decent ballscrews is the easiest precision homing system to implement (mechanically). Even then the ballscrews don't have to be special because as long as the ballscrew fixed bearings are good, a junky ballscrew is going to go to the same place when it's at the same angular rotation point.

If you don't plan on probing then how are you going to account for thermal growth - especially on the Z-axis (spindle heat)?

At the mechanical resolution you're discussing you need to take thermal growth in to account. That's done either through probing and/or mapping the machine movements using some serious instrumentation likely beyond the reach of most homegamers.

A good quality proximity sensor can get you within a few thousanths of a home position. Not too bad for a linear axis, but not really good enough for a rotary axis (error changes depending on distance from axis center).

Probing doesn't have to be slow. If you use a zero-point system you can preprogram a macro to probe the zero-point base (or a feature machined on all your pallets) and approach at rapid speed until just a few mm away. A 3-point double touch probe cycle shouldn't take more than 5-7 seconds (guess) at the start of the machining cycle. If you're worried about shaving 20 seconds off cycle time...

Back to your question... my inexpert opinion is that an Ethercat system with absolute encoders and decent ballscrews is the easiest precision homing system to implement (mechanically). Even then the ballscrews don't have to be special because as long as the ballscrew fixed bearings are good, a junky ballscrew is going to go to the same place when it's at the same angular rotation point.

The following user(s) said Thank You: Markgonz

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4653

- Thank you received: 2078

30 Jun 2023 06:05 #274486

by Aciera

Replied by Aciera on topic What would be the easiest way to get super accurate homing (milling machine)?

If your motor drives take care of precision homing then that is indeed the way to go although it may not necessarily be the easiest to implement in LinuxCNC.

My goto solution for precision homing using mesa hardware is the 'home to index' feature that uses an encoder index signal to reset the counter in the hardware.

My goto solution for precision homing using mesa hardware is the 'home to index' feature that uses an encoder index signal to reset the counter in the hardware.

The following user(s) said Thank You: endian

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

30 Jun 2023 13:47 #274509

by rodw

Replied by rodw on topic What would be the easiest way to get super accurate homing (milling machine)?

The Opencn guys used EtherCAT for their precision machines.

I think Ethercat with encoders and consider writing a custom homing module which is supported in 2.9 and higher.

I think Ethercat with encoders and consider writing a custom homing module which is supported in 2.9 and higher.

The following user(s) said Thank You: endian

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

01 Jul 2023 10:07 #274572

by andypugh

Replied by andypugh on topic What would be the easiest way to get super accurate homing (milling machine)?

Scales on the axes should give better results than encoders on the screws when you really want the best accuracy achievable.

There are some scales that have indices at different spacings, which mens that once you have found two indices and measured how many counts apart they are, you know exactly where you are.

There was discussion about implementing this on the forum within the last few years, and it was part of the reason for the work being done to allow custom homing modules.

There are some scales that have indices at different spacings, which mens that once you have found two indices and measured how many counts apart they are, you know exactly where you are.

There was discussion about implementing this on the forum within the last few years, and it was part of the reason for the work being done to allow custom homing modules.

The following user(s) said Thank You: rodw, endian, Markgonz

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 925

- Thank you received: 276

01 Jul 2023 17:27 #274611

by cakeslob

Replied by cakeslob on topic What would be the easiest way to get super accurate homing (milling machine)?

metrol-sensor.com/

This company makes really precision homing switches, as well as probes, toolsetters and other stuff. Reasonable priced also.

Im not personally doing it this way. I want to look into the ethercat option more

This company makes really precision homing switches, as well as probes, toolsetters and other stuff. Reasonable priced also.

Im not personally doing it this way. I want to look into the ethercat option more

The following user(s) said Thank You: Markgonz

Please Log in or Create an account to join the conversation.

- Markgonz

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

15 Jul 2023 13:48 #275506

by Markgonz

Replied by Markgonz on topic What would be the easiest way to get super accurate homing (milling machine)?

Thanks for your input, my problem is that my machine will have really short travels so a probe will likely not fit, so relaying on precision homing should be the way.

About termal growth I don't think should be an issue with a water cooled spindle that will operate during short cycles so barely gets warm.

About termal growth I don't think should be an issue with a water cooled spindle that will operate during short cycles so barely gets warm.

Please Log in or Create an account to join the conversation.

- Markgonz

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

15 Jul 2023 13:50 #275507

by Markgonz

Replied by Markgonz on topic What would be the easiest way to get super accurate homing (milling machine)?

Interesting, I would like to know if this solution can be done with servos that have integrated drivers like the ISHV57 from JMC

Please Log in or Create an account to join the conversation.

- Markgonz

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

15 Jul 2023 13:56 #275509

by Markgonz

Replied by Markgonz on topic What would be the easiest way to get super accurate homing (milling machine)?

This should be the best way no doubt, I will do research if really tiny ones are easy to find beacuse my micro mill has only 100mm travel on the axisScales on the axes should give better results than encoders on the screws when you really want the best accuracy achievable.

There are some scales that have indices at different spacings, which mens that once you have found two indices and measured how many counts apart they are, you know exactly where you are.

There was discussion about implementing this on the forum within the last few years, and it was part of the reason for the work being done to allow custom homing modules.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Markgonz

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

15 Jul 2023 14:12 - 15 Jul 2023 14:14 #275510

by Markgonz

Wow this is super interesting, never seen what these guys are doing but is exactly the kind of micro mill I want to build, although seems that they use really high end components as seems that their mill share parts with the micro5 mill that is made in Switzerland

<iframe width="560" height="315" src="" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen>

Surely they rely on precision homing on the servo drives because seems that they don't have glass scales

Replied by Markgonz on topic What would be the easiest way to get super accurate homing (milling machine)?

The Opencn guys used EtherCAT for their precision machines.

I think Ethercat with encoders and consider writing a custom homing module which is supported in 2.9 and higher.

Wow this is super interesting, never seen what these guys are doing but is exactly the kind of micro mill I want to build, although seems that they use really high end components as seems that their mill share parts with the micro5 mill that is made in Switzerland

<iframe width="560" height="315" src="" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen>

Surely they rely on precision homing on the servo drives because seems that they don't have glass scales

Last edit: 15 Jul 2023 14:14 by Markgonz.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- What would be the easiest way to get super accurate homing (milling machine)?

Time to create page: 0.096 seconds