First 7i96s/lathe build question: AC Servo driving spindle

- MarcosK

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 1

05 Jul 2023 07:02 - 05 Jul 2023 07:04 #274811

by MarcosK

First 7i96s/lathe build question: AC Servo driving spindle was created by MarcosK

Hi All,

I am planning my first build (a small lathe: EMCO Compact 5; using a Mesa 7i96s).

I am considering to use an AC Servo for the spindle. This servo has both a Step/Direction interface and it replicates the encoder's input as an output signal.

As far as I know, I need to:

- Link the servo (in a 1-to-1 gearing ration) to the spindle (removing all other native pulleys/gearing),

- Connect the servo drive to one of the step/dir interfaces of the 7i96s, and

- Connect the feedback/output to the 7i96s encoder input.

Question (assuming the HAL configuration is done right): will this work? specifically: will it be able to cut threads?

If not: why?, what would be missing or should be changed?

If it would work: is there any other configuration that would be clearly better to my end (to have a CNC driven lathe that can cut threads)?

FYI: I've considered driving the spindle with a 3-phase motor + VFD (known to work with the 7i96s), but I rather use an AC servo. Costs are comparable, but I like the simplification of the mechanics: given that all the original gearing would HAVE to be kept for a good torque and with the servo I can control the speed without fiddling with belts to keep it.

<BTW: If you object to this reasoning, please correct me as you see fit; remember it's my first one>

Thank you all for any tips you can provide!

I am planning my first build (a small lathe: EMCO Compact 5; using a Mesa 7i96s).

I am considering to use an AC Servo for the spindle. This servo has both a Step/Direction interface and it replicates the encoder's input as an output signal.

As far as I know, I need to:

- Link the servo (in a 1-to-1 gearing ration) to the spindle (removing all other native pulleys/gearing),

- Connect the servo drive to one of the step/dir interfaces of the 7i96s, and

- Connect the feedback/output to the 7i96s encoder input.

Question (assuming the HAL configuration is done right): will this work? specifically: will it be able to cut threads?

If not: why?, what would be missing or should be changed?

If it would work: is there any other configuration that would be clearly better to my end (to have a CNC driven lathe that can cut threads)?

FYI: I've considered driving the spindle with a 3-phase motor + VFD (known to work with the 7i96s), but I rather use an AC servo. Costs are comparable, but I like the simplification of the mechanics: given that all the original gearing would HAVE to be kept for a good torque and with the servo I can control the speed without fiddling with belts to keep it.

<BTW: If you object to this reasoning, please correct me as you see fit; remember it's my first one>

Thank you all for any tips you can provide!

Last edit: 05 Jul 2023 07:04 by MarcosK.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

05 Jul 2023 13:26 #274828

by PCW

Replied by PCW on topic First 7i96s/lathe build question: AC Servo driving spindle

That should work fine as long as the spindle stepgen is connected properly on hal

Its even possible to do this without encoder feedback by using the proper firmware

(though an index input is still required)

Its even possible to do this without encoder feedback by using the proper firmware

(though an index input is still required)

The following user(s) said Thank You: MarcosK

Please Log in or Create an account to join the conversation.

- zz912

-

- Offline

- Platinum Member

-

Less

More

- Posts: 585

- Thank you received: 95

05 Jul 2023 16:07 #274836

by zz912

Replied by zz912 on topic First 7i96s/lathe build question: AC Servo driving spindle

What specific AC servo are you planning to use?

Some servos have an encoder output on the driver, which could be connected to the 7i96s.

Some servos have an encoder output on the driver, which could be connected to the 7i96s.

Please Log in or Create an account to join the conversation.

- MarcosK

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 1

05 Jul 2023 20:21 #274847

by MarcosK

Replied by MarcosK on topic First 7i96s/lathe build question: AC Servo driving spindle

Yes, indeed (I think I did write that above).

This is it: www.omc-stepperonline.com/t6-series-750w...65-t6-rs750h2b3-m17s

Thanks for your reply. Have you tried something similar?

This is it: www.omc-stepperonline.com/t6-series-750w...65-t6-rs750h2b3-m17s

Thanks for your reply. Have you tried something similar?

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

06 Jul 2023 01:57 #274873

by spumco

Replied by spumco on topic First 7i96s/lathe build question: AC Servo driving spindle

Something to consider while you're still planning the lathe retrofit...

What is your spindle max speed? That is, the spindle itself and not just the motor? I'm sure the bearings and/or chuck are rated for some top end.

Reason I bring it up is that - on paper - the T6 servos are capable of 5k rpm, but your spindle and chuck might not be. In that case you might want to gear down the spindle and run a 1:1.5 or so belt reduction to gain some low end torque (for threading or larger diameters) while also limiting the max spindle RPM to something appropriate for your mechanical components.

If you do go that route, the T6 encoder output can still be used for threading, but you'll need some sort of spindle index trigger that's at a 1:1 ratio (as PCW mentioned)

And since I've never known someone to complain about too much low end torque on a lathe, note that the 1kw T6 servos are only slightly more money than the 750w versions.

I've just bought a set of the T6's for a build I'm doing now and am interested in how you make out using one as a spindle. I've got plans to make a 5C collet subspindle and would like to use another T6 to drive it.

What is your spindle max speed? That is, the spindle itself and not just the motor? I'm sure the bearings and/or chuck are rated for some top end.

Reason I bring it up is that - on paper - the T6 servos are capable of 5k rpm, but your spindle and chuck might not be. In that case you might want to gear down the spindle and run a 1:1.5 or so belt reduction to gain some low end torque (for threading or larger diameters) while also limiting the max spindle RPM to something appropriate for your mechanical components.

If you do go that route, the T6 encoder output can still be used for threading, but you'll need some sort of spindle index trigger that's at a 1:1 ratio (as PCW mentioned)

And since I've never known someone to complain about too much low end torque on a lathe, note that the 1kw T6 servos are only slightly more money than the 750w versions.

I've just bought a set of the T6's for a build I'm doing now and am interested in how you make out using one as a spindle. I've got plans to make a 5C collet subspindle and would like to use another T6 to drive it.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

06 Jul 2023 02:08 #274874

by spumco

Replied by spumco on topic First 7i96s/lathe build question: AC Servo driving spindle

And another thing...

If you plan on using the T6 encoder output to the 7i96s for threading, you'll want to use a timing belt (HTD or similar) rather than a V-belt or micro-v. If there's some belt slippage during heavier (relatively, of course) thread cutting LCNC won't know and the thread could be compromised.

A timing belt is noisier, but there won't be any belt slip and you can set the belt tension a bit lower than a micro-v for better bearing life.

If the timing belt noise drives you nuts (or you think it will), a micro-v belt can still work but you'd need a separate encoder connected directly to the spindle and driven with a timing belt (or an encoder wheel directly on the spindle itself). In that case if there's some belt slip or the belt ratio isn't exactly what you think it is, LCNC is reading the actual spindle speed and not just the motor speed.

Regarding the index trigger mentioned earlier, that can be as simple as a disc with a slot on the back of the spindle and an optical sensor. Slot goes past the sensor, LCNC sees it as the once-per-rev index.

If you plan on using the T6 encoder output to the 7i96s for threading, you'll want to use a timing belt (HTD or similar) rather than a V-belt or micro-v. If there's some belt slippage during heavier (relatively, of course) thread cutting LCNC won't know and the thread could be compromised.

A timing belt is noisier, but there won't be any belt slip and you can set the belt tension a bit lower than a micro-v for better bearing life.

If the timing belt noise drives you nuts (or you think it will), a micro-v belt can still work but you'd need a separate encoder connected directly to the spindle and driven with a timing belt (or an encoder wheel directly on the spindle itself). In that case if there's some belt slip or the belt ratio isn't exactly what you think it is, LCNC is reading the actual spindle speed and not just the motor speed.

Regarding the index trigger mentioned earlier, that can be as simple as a disc with a slot on the back of the spindle and an optical sensor. Slot goes past the sensor, LCNC sees it as the once-per-rev index.

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

06 Jul 2023 05:25 - 06 Jul 2023 05:31 #274878

by besriworld

Replied by besriworld on topic First 7i96s/lathe build question: AC Servo driving spindle

I have seen servo motors for axes that rotate a milling spindle. The only problem they mention is the motor temperature. Can you also use the original AC motor? With the right servo driver and feedback (the encoder can be on the spindle axis) it will work as a servo motor

PS: Now I saw the machine. I think you won't have a problem with high temperatures .

PS: Now I saw the machine. I think you won't have a problem with high temperatures .

Last edit: 06 Jul 2023 05:31 by besriworld.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

06 Jul 2023 13:56 #274891

by spumco

Replied by spumco on topic First 7i96s/lathe build question: AC Servo driving spindle

OP -

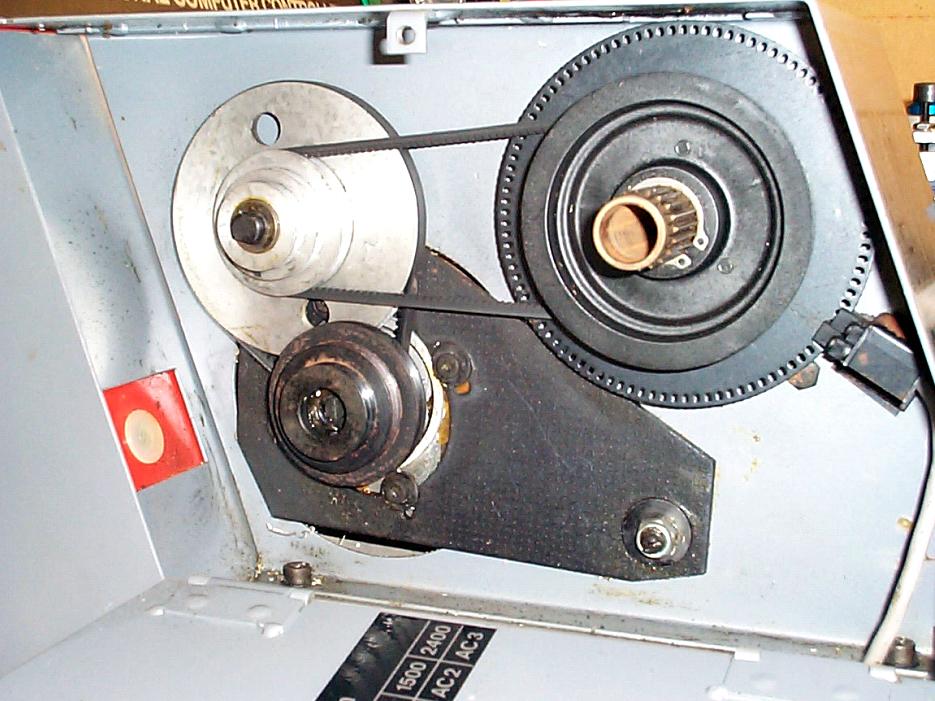

If the picture of a Compact 5 I found is accurate, you don't need anything complicated to thread.

This appears to be the Compact 5's spindle-mounted encoder wheel, and the original spindle motor appears to be a simple brushed DC motor, which I believe was rated at 440w.

Assuming you wish to pursue the servo motor path, the servo's encoder can be used as a (much) higher resolution feedback, and the original spindle plate replaced with one that has a single slot. Or fill one of the existing slots and use LCNC's "missing-tooth" function to trigger the index signal (search forum for 'missing tooth')

On the other hand, if you have the original DC motor drive LCNC can almost certainly control it as-is - probably using the 7i96s analog output. No further hardware or sensors would be required for threading as the encoder plate output can be connected to LCNC.

The article I found indicates the Compact 5 had a spindle range of 50-3200rpm, accomplished with a 3-position step pulley. As I mentioned before, if you switch to an AC servo you probably want to also change to a ~1.5:1 belt ratio and skip the multi-step pulley arrangement.

I'm pretty sure a 1kw servo driven at 1.5:1 should perform the same or better than the 400w DC motor with more reduction - and no fussing with belt changes.

If the picture of a Compact 5 I found is accurate, you don't need anything complicated to thread.

This appears to be the Compact 5's spindle-mounted encoder wheel, and the original spindle motor appears to be a simple brushed DC motor, which I believe was rated at 440w.

Assuming you wish to pursue the servo motor path, the servo's encoder can be used as a (much) higher resolution feedback, and the original spindle plate replaced with one that has a single slot. Or fill one of the existing slots and use LCNC's "missing-tooth" function to trigger the index signal (search forum for 'missing tooth')

On the other hand, if you have the original DC motor drive LCNC can almost certainly control it as-is - probably using the 7i96s analog output. No further hardware or sensors would be required for threading as the encoder plate output can be connected to LCNC.

The article I found indicates the Compact 5 had a spindle range of 50-3200rpm, accomplished with a 3-position step pulley. As I mentioned before, if you switch to an AC servo you probably want to also change to a ~1.5:1 belt ratio and skip the multi-step pulley arrangement.

I'm pretty sure a 1kw servo driven at 1.5:1 should perform the same or better than the 400w DC motor with more reduction - and no fussing with belt changes.

Attachments:

Please Log in or Create an account to join the conversation.

- EddySPalm

-

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

02 Apr 2024 21:29 #297470

by EddySPalm

Replied by EddySPalm on topic First 7i96s/lathe build question: AC Servo driving spindle

Hello, I am currently planning on doing a retrofit on the exact same machine, and also with a 7i96s.

I have always been under the impression that, if you use a motor with closed loop control with its driver, you will not need to supply encoder input to the controller. I thought the controller could/should simply rely on the servo system to "do its job" and that the user have set everything up correctly.

So, is it so that I am completely wrong, or would it be correct one could try without the encoder (index) input, only with less accuracy and redundancy?

I have always been under the impression that, if you use a motor with closed loop control with its driver, you will not need to supply encoder input to the controller. I thought the controller could/should simply rely on the servo system to "do its job" and that the user have set everything up correctly.

So, is it so that I am completely wrong, or would it be correct one could try without the encoder (index) input, only with less accuracy and redundancy?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

02 Apr 2024 21:41 #297471

by PCW

Replied by PCW on topic First 7i96s/lathe build question: AC Servo driving spindle

The index input is still required

How are you going to drive the spindle?

How are you going to drive the spindle?

Please Log in or Create an account to join the conversation.

Time to create page: 0.089 seconds