Debugging joint amplifier fault

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 13:15 - 28 Mar 2024 13:28 #296999

by knipknap

Debugging joint amplifier fault was created by knipknap

My machine (Kinematics XYYZ with 4 servos) has been running without a problem for months, but today I started getting "joint 2 amplifier fault". It happens quite quickly after starting any job now. Joint 2 is one of my dual Y axis joints.

I have not found any docs about what this error means. Any hint on where I should start debugging? I have not made any changes on the hardware nor software.

I have not found any docs about what this error means. Any hint on where I should start debugging? I have not made any changes on the hardware nor software.

Last edit: 28 Mar 2024 13:28 by knipknap.

Please Log in or Create an account to join the conversation.

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 14:34 - 28 Mar 2024 14:35 #297002

by knipknap

Replied by knipknap on topic Debugging joint amplifier fault

Turns out my joint 1 servo (not the one that is named in the error) is not working anymore, leading to joint 2 having trouble moving the gantry.

Checked the cabling of the non-working servo, all good. That leaves the servo (JMC with integrated driver) or the interface card (MESA 7176e) as a potential source of the problem.

Checked the cabling of the non-working servo, all good. That leaves the servo (JMC with integrated driver) or the interface card (MESA 7176e) as a potential source of the problem.

Last edit: 28 Mar 2024 14:35 by knipknap.

Please Log in or Create an account to join the conversation.

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 16:04 - 28 Mar 2024 16:31 #297010

by knipknap

Replied by knipknap on topic Debugging joint amplifier fault

It gets more puzzling:

- If a swap the two Y axis motors, they both work - if I swap them back, only one works. Repeatedly tried with the same result. In any case, both clearly have power, because if I try to move the non-working one manually, it tries to move back . I am confused. Could this be servo tuning related?

- In addition, on my destroyed workpiece I see that there was a large following error on the X axis, not just on Y.

Last edit: 28 Mar 2024 16:31 by knipknap.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5180

28 Mar 2024 17:12 #297013

by PCW

Replied by PCW on topic Debugging joint amplifier fault

Did you swap the motor connections at the 7I76E or the motor?

If differential signalling is used and you have either:

A bad cable

A bad 7I76E step output

A bad motor driver step input

You can get flaky behavior if just one on the differential

signals is working.

If differential signalling is used and you have either:

A bad cable

A bad 7I76E step output

A bad motor driver step input

You can get flaky behavior if just one on the differential

signals is working.

Please Log in or Create an account to join the conversation.

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 17:23 #297014

by knipknap

Replied by knipknap on topic Debugging joint amplifier fault

I swapped them at the motor side. I also made sure to check every wire with a beeper while moving the cable around, all wires seem fine. But I only checked the non-moving motor wires, not the other ones... maybe I'll check them all.

Please Log in or Create an account to join the conversation.

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 18:50 #297021

by knipknap

Replied by knipknap on topic Debugging joint amplifier fault

I just checked both channels with an oscilloscope:

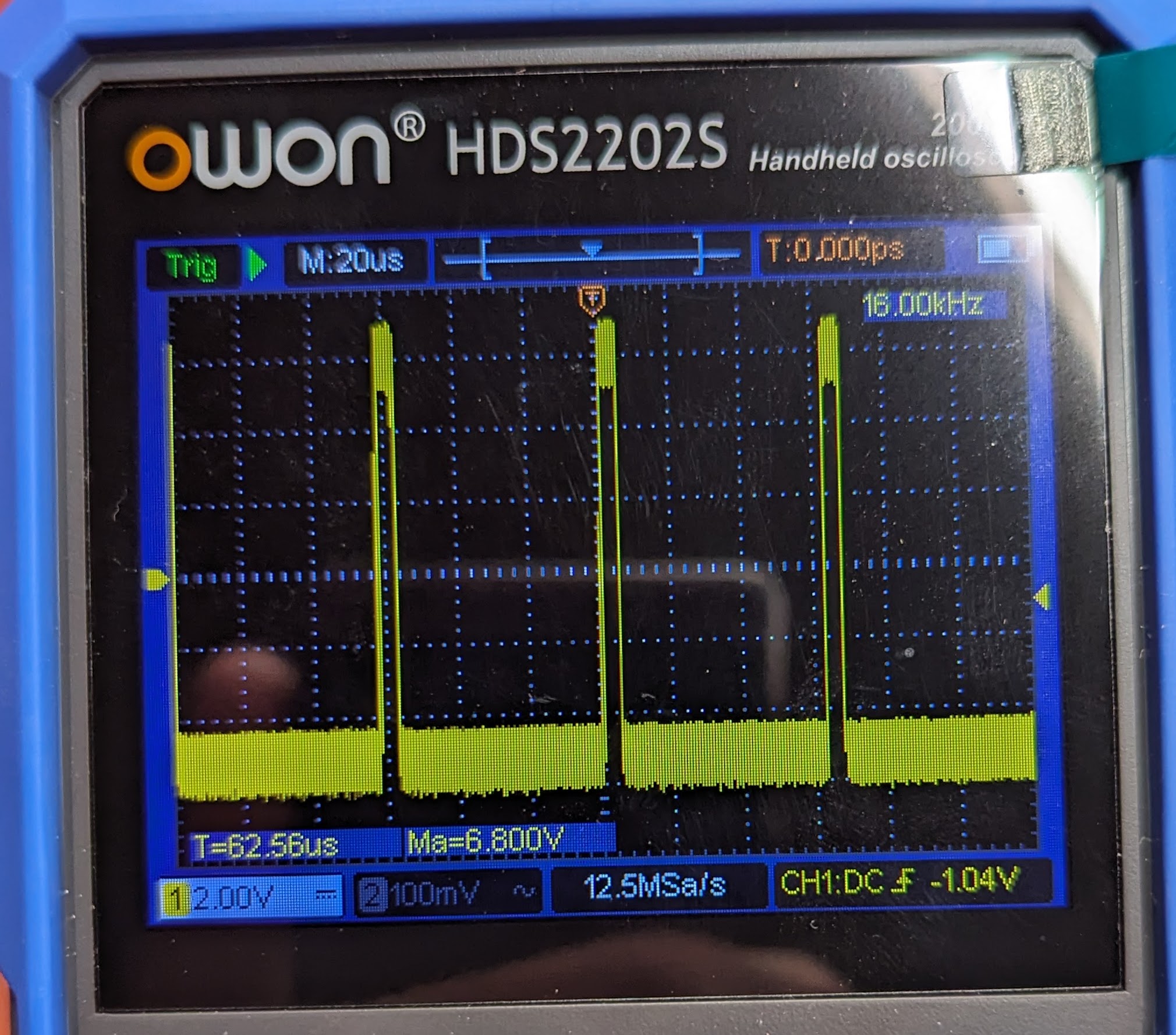

When disconnected, channel 1 looks like this:

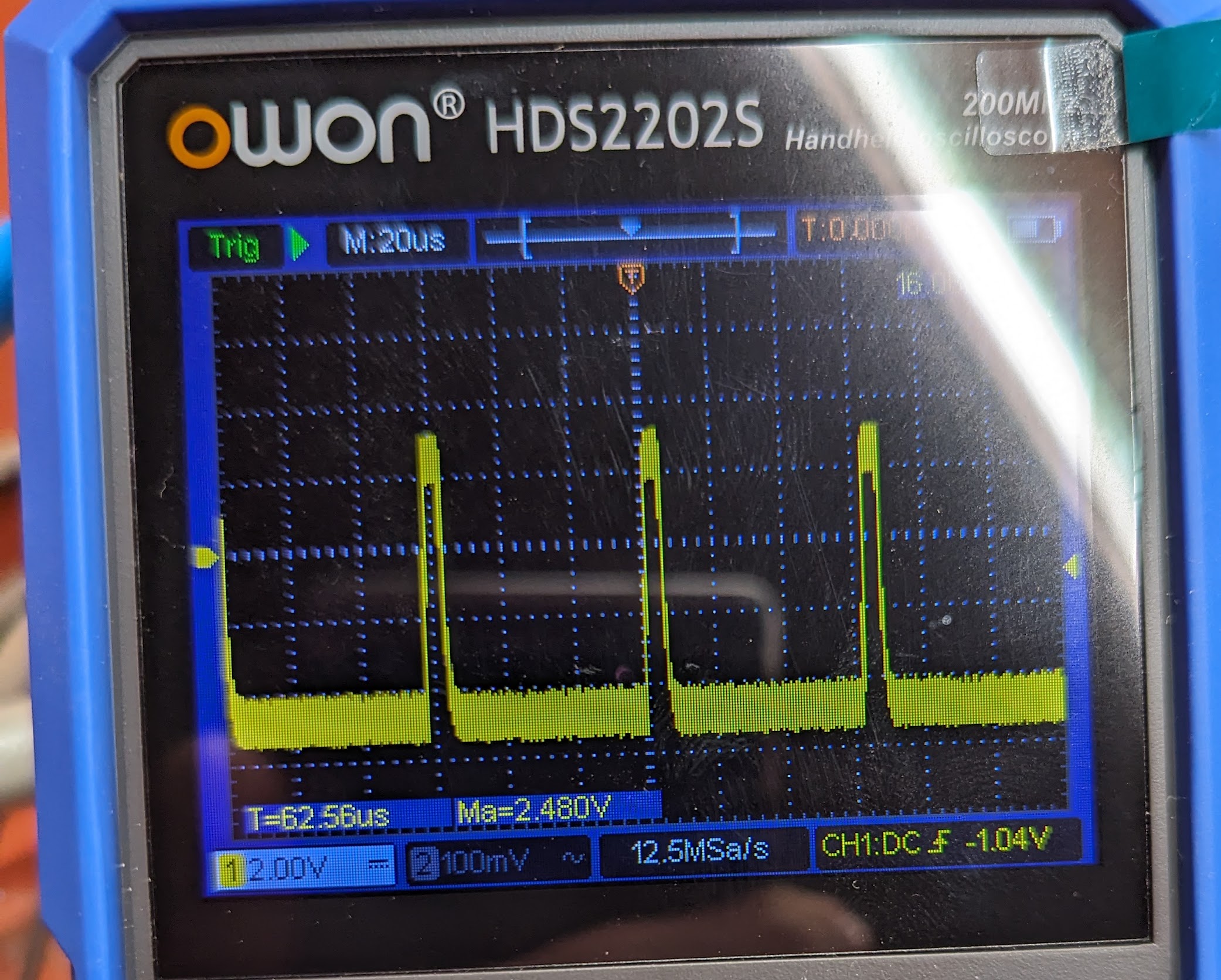

When connected, the pulses are way lower:

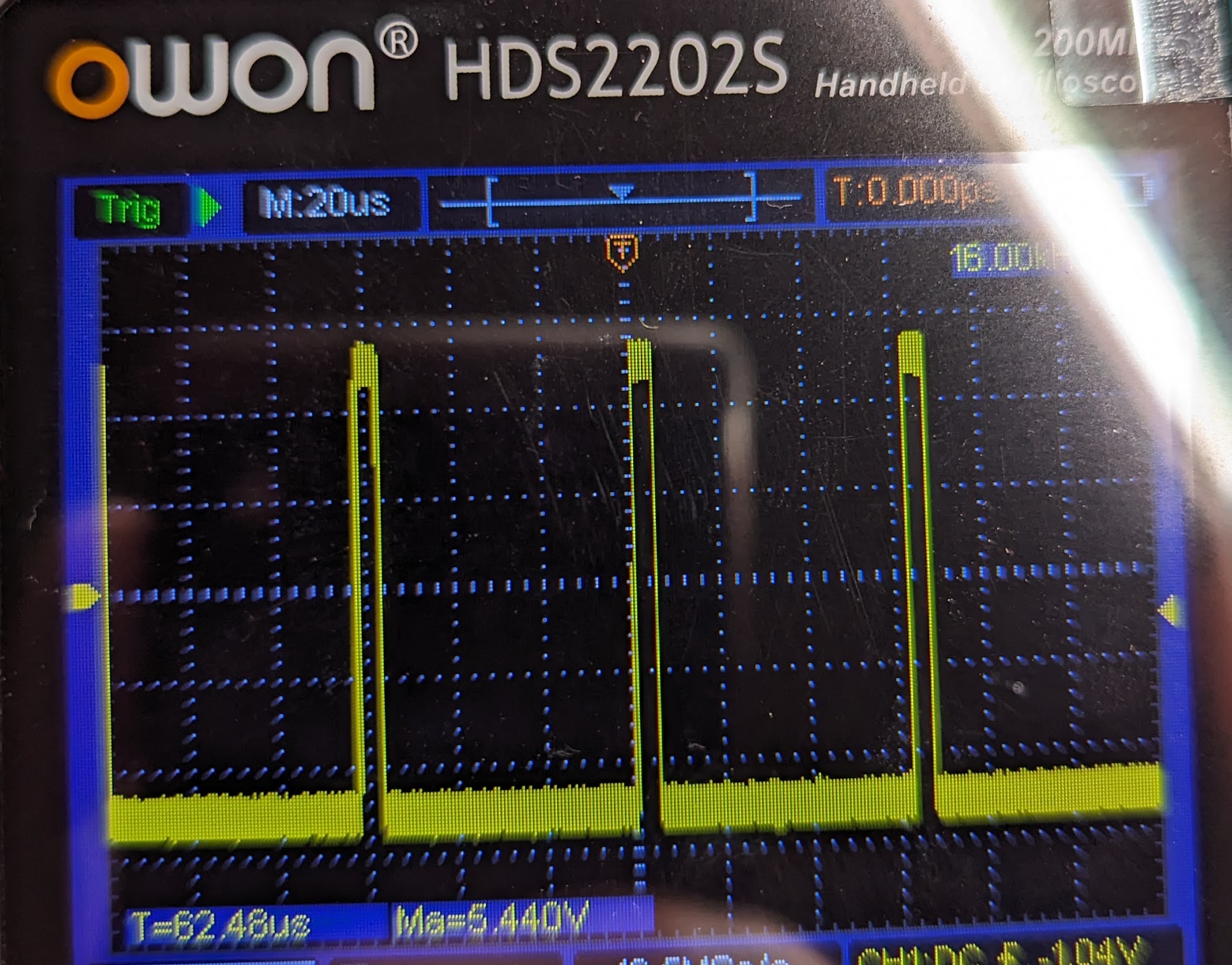

As a control, I also measured on channel 2 (when connected):

I also measured directly on the MESA connector in disconnected state, but both look the same in that case.

So I guess this means that there is a problem with the driver of the JMC...

- Once with the servos disconnected.

- Once with the servos connected, such that one doesn't work.

When disconnected, channel 1 looks like this:

When connected, the pulses are way lower:

As a control, I also measured on channel 2 (when connected):

I also measured directly on the MESA connector in disconnected state, but both look the same in that case.

So I guess this means that there is a problem with the driver of the JMC...

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5180

28 Mar 2024 19:13 #297023

by PCW

Replied by PCW on topic Debugging joint amplifier fault

A lower signal is expected especially with a differential inputs that typically

have 100 Ohm termination.

Did you check both STEP+ and STEP- (assuming you have differential connections)

have 100 Ohm termination.

Did you check both STEP+ and STEP- (assuming you have differential connections)

Please Log in or Create an account to join the conversation.

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 19:15 #297024

by knipknap

Replied by knipknap on topic Debugging joint amplifier fault

Lower yes, but why the large difference between both servos?

The above measurements are between step+ and step-.

The above measurements are between step+ and step-.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17708

- Thank you received: 5180

28 Mar 2024 19:38 #297027

by PCW

Replied by PCW on topic Debugging joint amplifier fault

So the large swing difference is traceable to just one drive? (and not one step/dir output)?

Please Log in or Create an account to join the conversation.

- knipknap

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 6

28 Mar 2024 19:52 #297030

by knipknap

Replied by knipknap on topic Debugging joint amplifier fault

Good question. The bad motor on the good channel is also pulled down a lot, but only to 3.7V instead of 2.4V.

The specs of the servo say they tolerate a signal voltage between 5V and 24V, so both is well below that.

I am really not sure who is at fault here; the MESA because it cannot provide enough power, or the driver because it pulls too much power.

The specs of the servo say they tolerate a signal voltage between 5V and 24V, so both is well below that.

I am really not sure who is at fault here; the MESA because it cannot provide enough power, or the driver because it pulls too much power.

Please Log in or Create an account to join the conversation.

Time to create page: 0.115 seconds