Encoder connection for threading on lathe

- EddySPalm

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

29 Apr 2024 14:29 #299321

by EddySPalm

Encoder connection for threading on lathe was created by EddySPalm

Hello,

I was hijacking another guy's similar thread about roughly the same subject, but I should really stop cluttering his thread now and make my own.

I have now bought some of the very common Chinese AC servos on aliexpress (Lichuan with A5 drives), and will be using them as both axis and spindle motors.

The spindle motor will drive the spindle with a 1:1 ratio, so the plan was to just use the encoder output from the servo drive as-is, directly into the encoder input on the 7i96s.

I have understood that an index pulse will be enough to do threading on the lathe (both single point and rigid?), but will it be beneficial to feed the A+, A-, B+ and B- pulses also? or will it just complicate things?

I was hijacking another guy's similar thread about roughly the same subject, but I should really stop cluttering his thread now and make my own.

I have now bought some of the very common Chinese AC servos on aliexpress (Lichuan with A5 drives), and will be using them as both axis and spindle motors.

The spindle motor will drive the spindle with a 1:1 ratio, so the plan was to just use the encoder output from the servo drive as-is, directly into the encoder input on the 7i96s.

I have understood that an index pulse will be enough to do threading on the lathe (both single point and rigid?), but will it be beneficial to feed the A+, A-, B+ and B- pulses also? or will it just complicate things?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17671

- Thank you received: 5166

29 Apr 2024 15:57 - 29 Apr 2024 20:29 #299323

by PCW

Replied by PCW on topic Encoder connection for threading on lathe

1 PPR threading should be OK with a servo spindle (its no good if the spindle speed varies)

But there is no direct support for this with Mesa encoders so its probably easiest to use A/B/I

Theoretically you could connect the drives index to the encoder A and I inputs and use interpolated position

but this has not been tried AFAIK.

Edit, I just tried this and it does seem to work:

1. Connect 1 PPR signal to Mesa encoder A and I.

2. Set encoder scale to 1 and count mode true.

3. Use encoders interpolated position (this may be in LinuxCNC 2.10 only)

But there is no direct support for this with Mesa encoders so its probably easiest to use A/B/I

Theoretically you could connect the drives index to the encoder A and I inputs and use interpolated position

but this has not been tried AFAIK.

Edit, I just tried this and it does seem to work:

1. Connect 1 PPR signal to Mesa encoder A and I.

2. Set encoder scale to 1 and count mode true.

3. Use encoders interpolated position (this may be in LinuxCNC 2.10 only)

Last edit: 29 Apr 2024 20:29 by PCW.

The following user(s) said Thank You: EddySPalm

Please Log in or Create an account to join the conversation.

- EddySPalm

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

30 Apr 2024 13:32 #299394

by EddySPalm

Replied by EddySPalm on topic Encoder connection for threading on lathe

Thank you PCW, I also see your post edit that I can actually just connect my 1PPR signal to the Mesa, though to both A and I connector.

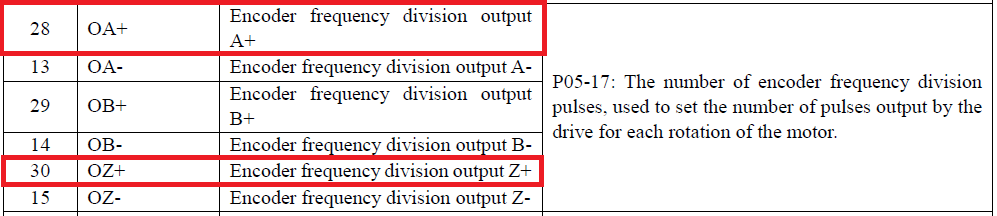

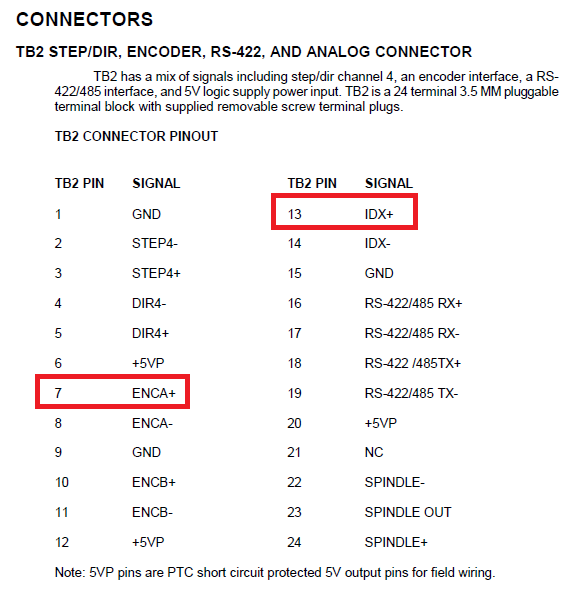

PS: I suppose i would use ENCA+ and IDX+ on the Mesa card, and OA+ and OZ+ on the servo drive.

If you wouldn't mind PCW, just for the sake of learning something new today; why do you suggest doing this? Will there be an advantage over just connecting them all up? I mean, I have all 6 outputs readily available on the driver, and all 6 corresponding connections on the mesa card.

or what about using it as a single ended encoder, with just A+, B+ and Z+ connected, which to a newbie liek me seems like a more "complete" setup, but still saving a little on connections.

PS: I suppose i would use ENCA+ and IDX+ on the Mesa card, and OA+ and OZ+ on the servo drive.

If you wouldn't mind PCW, just for the sake of learning something new today; why do you suggest doing this? Will there be an advantage over just connecting them all up? I mean, I have all 6 outputs readily available on the driver, and all 6 corresponding connections on the mesa card.

or what about using it as a single ended encoder, with just A+, B+ and Z+ connected, which to a newbie liek me seems like a more "complete" setup, but still saving a little on connections.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17671

- Thank you received: 5166

30 Apr 2024 14:33 - 30 Apr 2024 20:01 #299401

by PCW

Replied by PCW on topic Encoder connection for threading on lathe

I would use all 6 connections (fully differential)

just because its simpler to setup, has better noise

immunity than single ended, uses the standard hal setup,

and does not require LinuxCNC 2.10

I was mainly pointing out that 1 PPR threading should work well

with servo spindles since they should run at a very constant speed

(unlike say a VFD with varying load and LinuxCNC just guessing the

speed between index pulses)

just because its simpler to setup, has better noise

immunity than single ended, uses the standard hal setup,

and does not require LinuxCNC 2.10

I was mainly pointing out that 1 PPR threading should work well

with servo spindles since they should run at a very constant speed

(unlike say a VFD with varying load and LinuxCNC just guessing the

speed between index pulses)

Last edit: 30 Apr 2024 20:01 by PCW.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- EddySPalm

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

30 Apr 2024 19:13 #299415

by EddySPalm

Replied by EddySPalm on topic Encoder connection for threading on lathe

That makes perfect sense, thanks

Please Log in or Create an account to join the conversation.

Time to create page: 0.137 seconds