Make arc in W axis

- RLA

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 2

Thanks for any help,

Rick

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4613

- Thank you received: 2042

[edit]

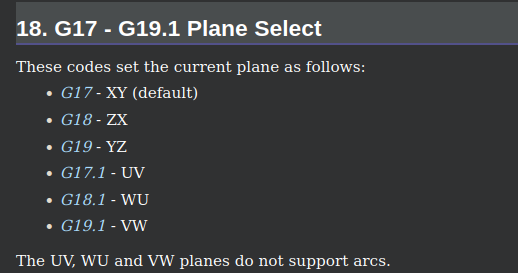

linuxcnc.org/docs/html/gcode/g-code.html#gcode:g17-g19.1

Attachments:

Please Log in or Create an account to join the conversation.

- RLA

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 2

Thanks again,

Rick

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4613

- Thank you received: 2042

It is not possible to execute two arcs simultaneously. What you could do is use the switchable kinematics feature to switch the X and Z axes to different joints. So you could run regular gcode with arcs in the XZ plane and switch in gcode on which side of the work piece the movement takes place. Remember though that this is possible only one after the other not both simultaneously.So that is at least two axis on opposing sides sometimes doing arcs simultaneously...

Arc moves are really only defined for linear axes XY, XZ or YZ. If you need different linear axes to perform arcs then switching the joint/axes mapping using switchable kinematics seems to be the only way to go.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4689

- Thank you received: 1433

Imagine each line of g-code as a frame of a movie film, with each new line of g-code as an image of each axis' position at the frame rate's time interval. The difference being, unlike in a film the size of your time interval can be variable. For all linear moves you would only need a frame at the beginning and end. But for anything else the interval can be as small as you need to achieve your desired resolution.

Please Log in or Create an account to join the conversation.

- RLA

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 2

Thanks!!!

Please Log in or Create an account to join the conversation.

- RLA

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 2

Thanks again!!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4689

- Thank you received: 1433

To do what I think your asking for, you would almost have to have two separate G-code interpreters executing two separate, yet some how synchronized g-code files. I think there are some high end control systems that can do such things, but it is currently beyond the scope of Linuxcnc.

That said, I think I can imagine two separate Linuxcnc control computers on one machine linked with some of digital io bits to synchronize a set of parallel processed files. It could work, but would require some experimentation, and there may be unforeseen pitfalls.

Please Log in or Create an account to join the conversation.

- RLA

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 2

Thanks,

Rick

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4613

- Thank you received: 2042

I don't see why that would not work. Basically a tandem axis, one axis mapped to two joints.I was thinking of using 2 different drivers with different microstepping...does not seem to work...any other workarounds?

Please Log in or Create an account to join the conversation.