Electronic Gear Ratio on survo drive and setting pulses in ini

- mjones@welfab.ca

- Offline

- Premium Member

-

Less

More

- Posts: 95

- Thank you received: 6

03 Dec 2024 22:34 #315921

by mjones@welfab.ca

Electronic Gear Ratio on survo drive and setting pulses in ini was created by mjones@welfab.ca

Hi Guys.

I'm trying to figure out my motor tuning for steps per inch. I'm guessing I need to use electronic gear ratio in my servo drive to be able to handle the amount of pulses per inch. Right now if I set an encoder count of (and i'm just playing right now to speed it up) 2500, and a step count of 500000 and I tell it to move .100 it only moves approx. .002 with different variations I can only get approx .011 per .100 request.

So what would be the best electronic ratio

As near as I can figure at this time my ball screws are 5 turns per inch or .200 per rev. (Hardenge SuperSlant, Maybe someone knows for sure the pitch)

it is belt driven from the survo 2 turns of the motor to one turn of the ball screw

The information I find for the motor and encoder says it has 2500 lines per rev.

So I'm thinking 2500x 5(ballscrew)= 12,500 x 2(gearing)= 25000 and this is nothing for a computer to handle but if i work on this figure the axis doesn't move enough to read on a dial indicator.

I am obviously missing something big because of the amount of pulses I actualy have to put out to get any readable movement per .1 request.

In case you might think it helps. My survo's and drives are chinese the drives are lichuan A6 drives Below copied from manual. I only wanted one line but it would only let me copy from top of page to that line.

A6 Servo Drive User Manual

2

Chapter 2 Electrical Specifications

2.1 Specification

Input power

CONTROL

POWER Single phase 220 VAC

MAIN POWER

SUPPLY Single Phase/Three Phase 220VAC

Working

environment

Temperature 0~45℃

Humidity No condensation ≤90% RH or less

Elevation Altitude ≤1000M

Installation

environment Non-corrosive gases, flammable gases, oil mist or dust, etc.

Installation

method VERTICAL INSTALLATION

Encoder feedback 2500 p/r (resolution: 10000), incremental encode

I'm trying to figure out my motor tuning for steps per inch. I'm guessing I need to use electronic gear ratio in my servo drive to be able to handle the amount of pulses per inch. Right now if I set an encoder count of (and i'm just playing right now to speed it up) 2500, and a step count of 500000 and I tell it to move .100 it only moves approx. .002 with different variations I can only get approx .011 per .100 request.

So what would be the best electronic ratio

As near as I can figure at this time my ball screws are 5 turns per inch or .200 per rev. (Hardenge SuperSlant, Maybe someone knows for sure the pitch)

it is belt driven from the survo 2 turns of the motor to one turn of the ball screw

The information I find for the motor and encoder says it has 2500 lines per rev.

So I'm thinking 2500x 5(ballscrew)= 12,500 x 2(gearing)= 25000 and this is nothing for a computer to handle but if i work on this figure the axis doesn't move enough to read on a dial indicator.

I am obviously missing something big because of the amount of pulses I actualy have to put out to get any readable movement per .1 request.

In case you might think it helps. My survo's and drives are chinese the drives are lichuan A6 drives Below copied from manual. I only wanted one line but it would only let me copy from top of page to that line.

A6 Servo Drive User Manual

2

Chapter 2 Electrical Specifications

2.1 Specification

Input power

CONTROL

POWER Single phase 220 VAC

MAIN POWER

SUPPLY Single Phase/Three Phase 220VAC

Working

environment

Temperature 0~45℃

Humidity No condensation ≤90% RH or less

Elevation Altitude ≤1000M

Installation

environment Non-corrosive gases, flammable gases, oil mist or dust, etc.

Installation

method VERTICAL INSTALLATION

Encoder feedback 2500 p/r (resolution: 10000), incremental encode

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

03 Dec 2024 23:32 - 03 Dec 2024 23:46 #315924

by PCW

Replied by PCW on topic Electronic Gear Ratio on survo drive and setting pulses in ini

I would set the drives steps per turn equal to the encoder resolution

(10K counts per turn with 4x quadrature)

Then the step scaling in LinuxCNC is 100000

(10000 CPT *5 TPI *2 Belt_division)

(10K counts per turn with 4x quadrature)

Then the step scaling in LinuxCNC is 100000

(10000 CPT *5 TPI *2 Belt_division)

Last edit: 03 Dec 2024 23:46 by PCW.

Please Log in or Create an account to join the conversation.

- mjones@welfab.ca

- Offline

- Premium Member

-

Less

More

- Posts: 95

- Thank you received: 6

03 Dec 2024 23:59 #315926

by mjones@welfab.ca

Replied by mjones@welfab.ca on topic Electronic Gear Ratio on survo drive and setting pulses in ini

Thank you. You make it sound so easy. I will try that in the morning when I'm back at the shop.

I really appreciate the input. Will let you know how it turns out.

The response times from you guys as awesome.

I really appreciate the input. Will let you know how it turns out.

The response times from you guys as awesome.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- mjones@welfab.ca

- Offline

- Premium Member

-

Less

More

- Posts: 95

- Thank you received: 6

04 Dec 2024 15:05 #315960

by mjones@welfab.ca

Replied by mjones@welfab.ca on topic Electronic Gear Ratio on survo drive and setting pulses in ini

Ok I tried the numbers suggested and I'm only getting .002" for a .100" request. I must have something in the driver itself thats not right.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

04 Dec 2024 16:18 #315963

by PCW

Replied by PCW on topic Electronic Gear Ratio on survo drive and setting pulses in ini

.002 motion from a 0.100 command is what you would expect

if you used 100000 as the step scale but the drive was set for

500000 steps/turn instead of 10000.

if you used 100000 as the step scale but the drive was set for

500000 steps/turn instead of 10000.

Please Log in or Create an account to join the conversation.

- mjones@welfab.ca

- Offline

- Premium Member

-

Less

More

- Posts: 95

- Thank you received: 6

04 Dec 2024 16:39 #315965

by mjones@welfab.ca

Replied by mjones@welfab.ca on topic Electronic Gear Ratio on survo drive and setting pulses in ini

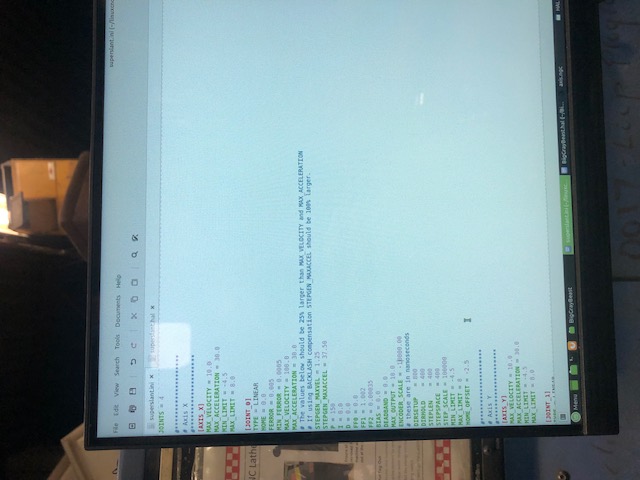

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17748

- Thank you received: 5189

04 Dec 2024 17:35 #315973

by PCW

Replied by PCW on topic Electronic Gear Ratio on survo drive and setting pulses in ini

if the step scale is 100000, you should get 1 turn of the shaft for a .1" move

if the drive is set for 10000 steps per turn.

If not, the drives steps/turn or encoder resolution are probably not set properly

if the drive is set for 10000 steps per turn.

If not, the drives steps/turn or encoder resolution are probably not set properly

Please Log in or Create an account to join the conversation.

- mjones@welfab.ca

- Offline

- Premium Member

-

Less

More

- Posts: 95

- Thank you received: 6

04 Dec 2024 17:48 #315976

by mjones@welfab.ca

Replied by mjones@welfab.ca on topic Electronic Gear Ratio on survo drive and setting pulses in ini

I am going through the Drive and the manual to try and figure that out.. From what I have found so far it is all good, but I must be missing something some where. I have an encoder connected back to the 7i77 but not able to see the counts for some reason.

Please Log in or Create an account to join the conversation.

- mjones@welfab.ca

- Offline

- Premium Member

-

Less

More

- Posts: 95

- Thank you received: 6

04 Dec 2024 18:27 #315981

by mjones@welfab.ca

Replied by mjones@welfab.ca on topic Electronic Gear Ratio on survo drive and setting pulses in ini

Problem solved.

Nothing to do with the drive and your setting were right on.

I was reading another thread about 'Whitch mode is best for new setups' it has alot of interesting stuff. still ready it as I'm hoping to see how they resolve tying the encoder feedback into linuxcnc.

Any ways in that thread they were talking about missed steps due to step and direction times being to small. I seen the number they were talking about ( in the thousands) and mine are just 400 and 800. Mine was a bit jerky and i figured maybe a bearing I would have to replace later, but suddenly made sense if its missing steps then it would be jerky as it missed and picked up again. I must have been loosing massive amounts of steps.. I changed my numbers to the below and now it moves smooth and the right distance.

Step Time=2000

Step Space=2000

Dir Hold=50000

Dir Setup=2000

I am so happy to me past this hurdle. Now on to the next.

I thank you so much for the help and efforts. unfortunately I am sure you will hear from me again when I hit the next wall.

I'm So thankful you guys are here for us that are struggling.

Nothing to do with the drive and your setting were right on.

I was reading another thread about 'Whitch mode is best for new setups' it has alot of interesting stuff. still ready it as I'm hoping to see how they resolve tying the encoder feedback into linuxcnc.

Any ways in that thread they were talking about missed steps due to step and direction times being to small. I seen the number they were talking about ( in the thousands) and mine are just 400 and 800. Mine was a bit jerky and i figured maybe a bearing I would have to replace later, but suddenly made sense if its missing steps then it would be jerky as it missed and picked up again. I must have been loosing massive amounts of steps.. I changed my numbers to the below and now it moves smooth and the right distance.

Step Time=2000

Step Space=2000

Dir Hold=50000

Dir Setup=2000

I am so happy to me past this hurdle. Now on to the next.

I thank you so much for the help and efforts. unfortunately I am sure you will hear from me again when I hit the next wall.

I'm So thankful you guys are here for us that are struggling.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.096 seconds