Feedback control XY not full speed run G1 when curve or Arc

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

07 Dec 2024 06:38 #316160

by abdulasis12

Feedback control XY not full speed run G1 when curve or Arc was created by abdulasis12

Hi

I use servo motor 750W and encoder from motor connect to 7i77 X and Y axis Feedback control

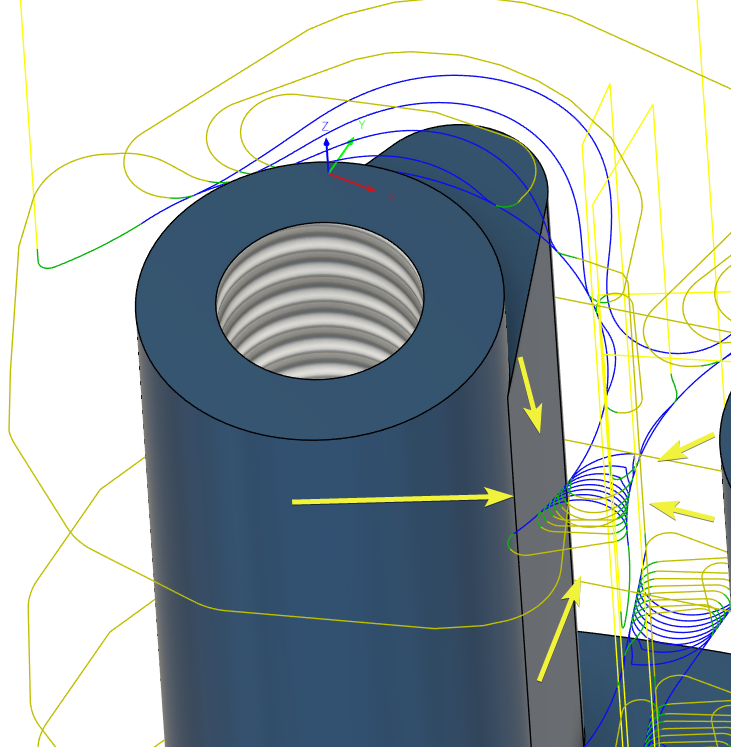

I use fusion360 for CAM and option G64 P0.002 Q0.002

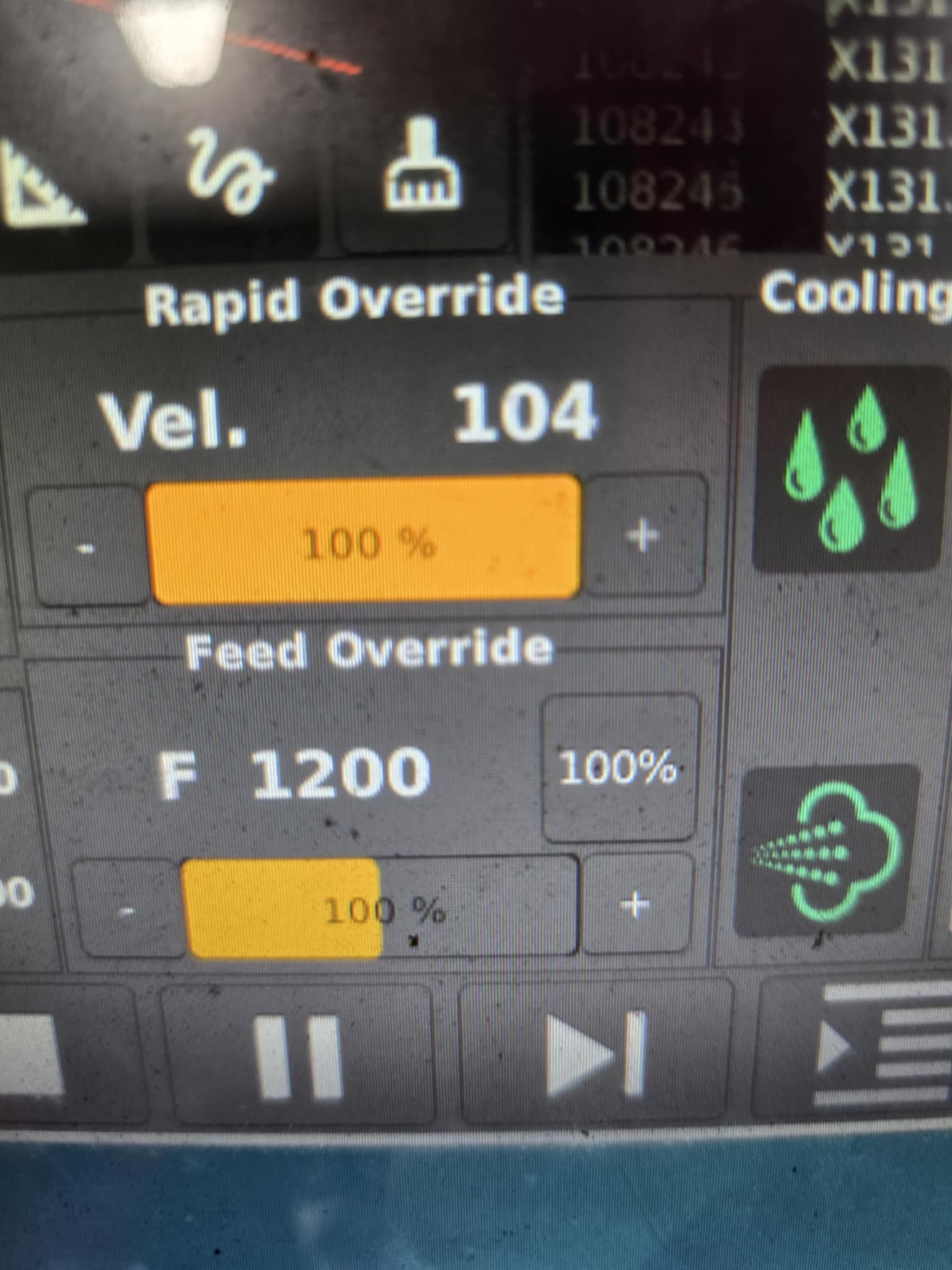

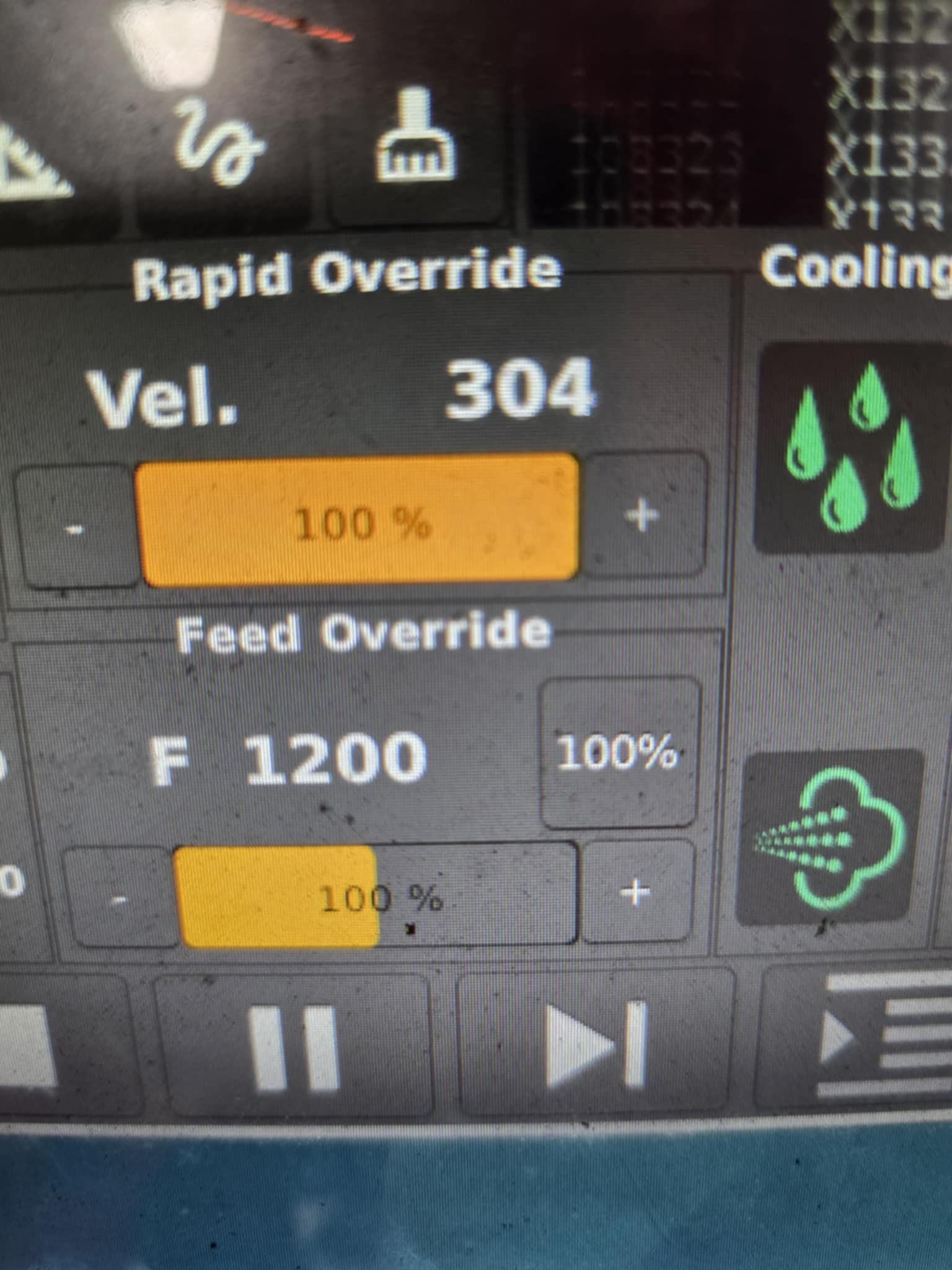

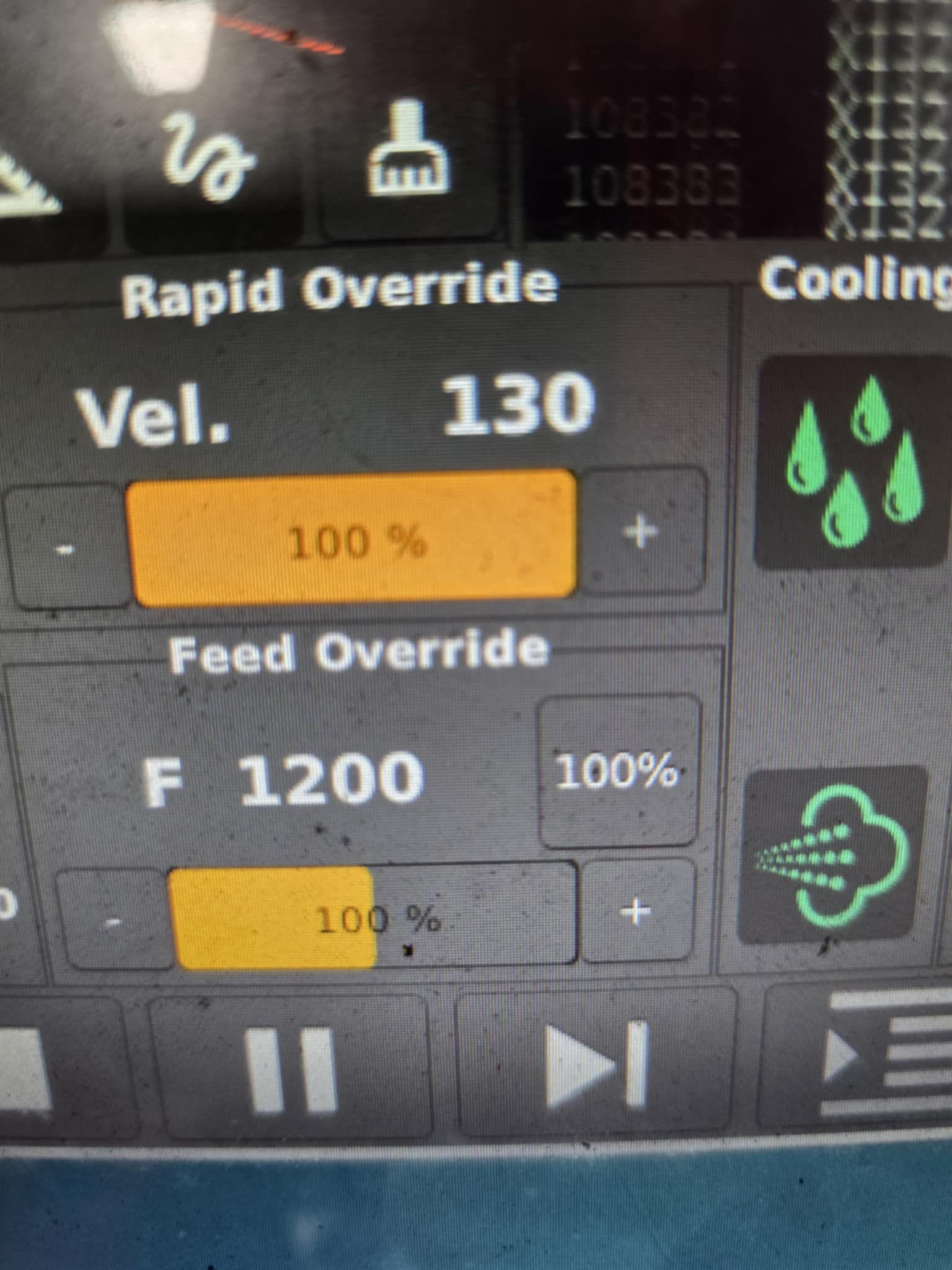

when my cnc run process Adaptive clearing toolpath is curve or Arc I few cnc base little jerky and feed in Gcode(G1) is 1200 mm/mins but CNC just run 100-300 mm/mins

How to fix this problem ?

I don't know where setting wrong.

Thank you

Asis

I use servo motor 750W and encoder from motor connect to 7i77 X and Y axis Feedback control

I use fusion360 for CAM and option G64 P0.002 Q0.002

when my cnc run process Adaptive clearing toolpath is curve or Arc I few cnc base little jerky and feed in Gcode(G1) is 1200 mm/mins but CNC just run 100-300 mm/mins

How to fix this problem ?

I don't know where setting wrong.

Thank you

Asis

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

07 Dec 2024 08:31 #316166

by Aciera

Replied by Aciera on topic Feedback control XY not full speed run G1 when curve or Arc

Can you post your gcode or at least a section of it?

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

07 Dec 2024 13:49 #316189

by tommylight

Replied by tommylight on topic Feedback control XY not full speed run G1 when curve or Arc

Also, what acceleration is set in the ini file?

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

08 Dec 2024 17:34 #316261

by abdulasis12

Replied by abdulasis12 on topic Feedback control XY not full speed run G1 when curve or Arc

Hi, MR.ACIERA MR. TOMMY

Thank you for reply and sorry in weekend slow reply.

This below post file gcode problem.

example about in gcode file at N15 to N3900

**Also, what acceleration is set in the ini file?**

Tomorow at workshop I will check and told again.

Thank you

Asis,

Thank you for reply and sorry in weekend slow reply.

This below post file gcode problem.

example about in gcode file at N15 to N3900

**Also, what acceleration is set in the ini file?**

Tomorow at workshop I will check and told again.

Thank you

Asis,

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

09 Dec 2024 08:55 #316314

by abdulasis12

Replied by abdulasis12 on topic Feedback control XY not full speed run G1 when curve or Arc

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

09 Dec 2024 12:33 #316324

by tommylight

Replied by tommylight on topic Feedback control XY not full speed run G1 when curve or Arc

Traj section in the ini file, velocities are much lower than in the display section, try setting those same as display section.

Please Log in or Create an account to join the conversation.

- hmnijp

- Away

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 45

09 Dec 2024 17:46 #316350

by hmnijp

Replied by hmnijp on topic Feedback control XY not full speed run G1 when curve or Arc

You should increase motion blending tolerance (g64 p0.002)

The more accurate the tolerance -> the lower the speed.

For roughing operation (adaptive) such accuracy is not required. Try setting P0.05, this will smooth the trajectory and allow it to be executed at high speed.

If the acceleration of your machine is not high, then for roughing operation you can choose P even more.

The more accurate the tolerance -> the lower the speed.

For roughing operation (adaptive) such accuracy is not required. Try setting P0.05, this will smooth the trajectory and allow it to be executed at high speed.

If the acceleration of your machine is not high, then for roughing operation you can choose P even more.

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

13 Dec 2024 01:27 #316558

by abdulasis12

"much lower than in the display section" Okay, I got it wrong. I think it's for the motor velocity. I will change it back to default.

Thank you,

Asis

Replied by abdulasis12 on topic Feedback control XY not full speed run G1 when curve or Arc

Hi MR.TommyTraj section in the ini file, velocities are much lower than in the display section, try setting those same as display section.

"much lower than in the display section" Okay, I got it wrong. I think it's for the motor velocity. I will change it back to default.

Thank you,

Asis

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

13 Dec 2024 01:35 #316559

by abdulasis12

Thank you for the suggestion. I have applied your advice and made some adjustments. Previously, it was G64 P0.002 Q0.002. Now, I’ve changed it to G64 P0.01 and removed the Q0.002 parameter. The machine runs much more smoothly, although there are still some slight jerks when transitioning into curves during G0 moves. However, it’s a significant improvement.

Do you happen to know what the Q parameter is used for?

Thank you,

Asis

Replied by abdulasis12 on topic Feedback control XY not full speed run G1 when curve or Arc

Hi MR.hmnijpYou should increase motion blending tolerance (g64 p0.002)

The more accurate the tolerance -> the lower the speed.

For roughing operation (adaptive) such accuracy is not required. Try setting P0.05, this will smooth the trajectory and allow it to be executed at high speed.

If the acceleration of your machine is not high, then for roughing operation you can choose P even more.

Thank you for the suggestion. I have applied your advice and made some adjustments. Previously, it was G64 P0.002 Q0.002. Now, I’ve changed it to G64 P0.01 and removed the Q0.002 parameter. The machine runs much more smoothly, although there are still some slight jerks when transitioning into curves during G0 moves. However, it’s a significant improvement.

Do you happen to know what the Q parameter is used for?

Thank you,

Asis

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

13 Dec 2024 06:39 #316563

by Aciera

Replied by Aciera on topic Feedback control XY not full speed run G1 when curve or Arc

Maybe this documentation helps:

linuxcnc.org/docs/stable/html/user/user-...gramming-the-planner

linuxcnc.org/docs/stable/html/user/user-...gramming-the-planner

The following user(s) said Thank You: Lcvette, abdulasis12

Please Log in or Create an account to join the conversation.

Time to create page: 0.287 seconds