Plasma center punching operation

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

27 Apr 2025 15:19 - 27 Apr 2025 15:26 #327168

by acourtjester

Plasma center punching operation was created by acourtjester

Hi

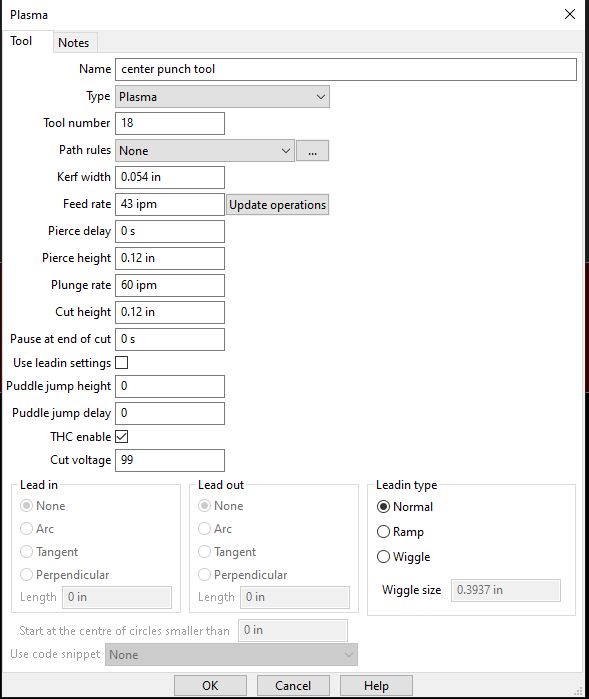

I have developed a method to center punch locations for drilling holes on my PlasmaCNC setup.I use CAD software (Fusion 360) to locate where I want holes drilled in my finished cut parts. I use fusion to show the location and size of the holes and then use the snap function to locate the centers. I do this with the circle sketch function snapped to the center then draw a 0.003” dot there. After saving in DXF format and importing into SheetCam I change the layer of the dots to separate the center punching from the normal cutting operations. I then have a tool in SheetCam that has the perimeter for the center punching operations. This has the pierce and cut height set at the same height and lower the Amps some for this operation. After planning the whole operation I select the center punching functions into on G-code and then the cutting function into another G-code. SheetCam will ID the center punching as a inside cut and you can make one G-code where it will do the 2 operations in the same G-code. QTPlasmaC seems to have a quicker response for this operation then I had with other controller software, but both produce a very nice dimple in the metal.Attached are images of the center punches and a video of the operation. I have used this method on different thickness metal with thin metal using the fine cut nozzle. I have used it to create a template for hole marking by center punching a thin plate to transfer the locations on another project surface.

drive.google.com/file/d/1EtZ_7zD49-VbqYf...sVL/view?usp=sharing

I have developed a method to center punch locations for drilling holes on my PlasmaCNC setup.I use CAD software (Fusion 360) to locate where I want holes drilled in my finished cut parts. I use fusion to show the location and size of the holes and then use the snap function to locate the centers. I do this with the circle sketch function snapped to the center then draw a 0.003” dot there. After saving in DXF format and importing into SheetCam I change the layer of the dots to separate the center punching from the normal cutting operations. I then have a tool in SheetCam that has the perimeter for the center punching operations. This has the pierce and cut height set at the same height and lower the Amps some for this operation. After planning the whole operation I select the center punching functions into on G-code and then the cutting function into another G-code. SheetCam will ID the center punching as a inside cut and you can make one G-code where it will do the 2 operations in the same G-code. QTPlasmaC seems to have a quicker response for this operation then I had with other controller software, but both produce a very nice dimple in the metal.Attached are images of the center punches and a video of the operation. I have used this method on different thickness metal with thin metal using the fine cut nozzle. I have used it to create a template for hole marking by center punching a thin plate to transfer the locations on another project surface.

drive.google.com/file/d/1EtZ_7zD49-VbqYf...sVL/view?usp=sharing

Attachments:

Last edit: 27 Apr 2025 15:26 by acourtjester.

The following user(s) said Thank You: JT, ARCANGELWELDINGMT

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

01 May 2025 05:35 #327404

by Aciera

Replied by Aciera on topic Plasma center punching operation

Thanks for sharing!

The following user(s) said Thank You: acourtjester

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

01 May 2025 13:18 #327430

by acourtjester

Replied by acourtjester on topic Plasma center punching operation

Happy to help, just a small payback for all the help I have received in the past from this site and members.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.244 seconds