- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Starting from scratch (again) - need help (apparently a lot)

Starting from scratch (again) - need help (apparently a lot)

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5162

04 Jan 2020 17:51 #154003

by PCW

Replied by PCW on topic Starting from scratch (again) - need help (apparently a lot)

I would use a minimum of 5000 ns step lengths unless it interferes with the maximum

attainable velocity. Using drive values ( which are typically _minimums_ ) is asking for

trouble...

attainable velocity. Using drive values ( which are typically _minimums_ ) is asking for

trouble...

The following user(s) said Thank You: mooser

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

04 Jan 2020 18:01 - 04 Jan 2020 18:01 #154004

by mooser

Replied by mooser on topic Starting from scratch (again) - need help (apparently a lot)

Interesting

I'd already set them to 2000 (and found out that when you run pncconf again and it's still set to 203v it resets it back to 1000 so I've changed it to custom)

Any suggestions to the step space, dir hold settings?

Changed them both up to 5000 now

M

I'd already set them to 2000 (and found out that when you run pncconf again and it's still set to 203v it resets it back to 1000 so I've changed it to custom)

Any suggestions to the step space, dir hold settings?

Changed them both up to 5000 now

M

Last edit: 04 Jan 2020 18:01 by mooser.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5162

04 Jan 2020 18:37 #154009

by PCW

Replied by PCW on topic Starting from scratch (again) - need help (apparently a lot)

I usually suggest

Steplen 5000

Stepspace 5000

DirSetup 20000

DirHold 20000

As a starting point since these will work with almost any drive,

and there is no disadvantage to long times until they limit your

maximum velocity.

Steplen 5000

Stepspace 5000

DirSetup 20000

DirHold 20000

As a starting point since these will work with almost any drive,

and there is no disadvantage to long times until they limit your

maximum velocity.

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

04 Jan 2020 18:48 #154010

by mooser

Replied by mooser on topic Starting from scratch (again) - need help (apparently a lot)

20000 (wow)

OK, i'll reset them as see if they cause any issues once this is connected to the actual machine bed.

Wiring in the limit switches now, Spindle is next

M

OK, i'll reset them as see if they cause any issues once this is connected to the actual machine bed.

Wiring in the limit switches now, Spindle is next

M

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

20 Jan 2020 01:10 - 20 Jan 2020 01:11 #155217

by mooser

Replied by mooser on topic Starting from scratch (again) - need help (apparently a lot)

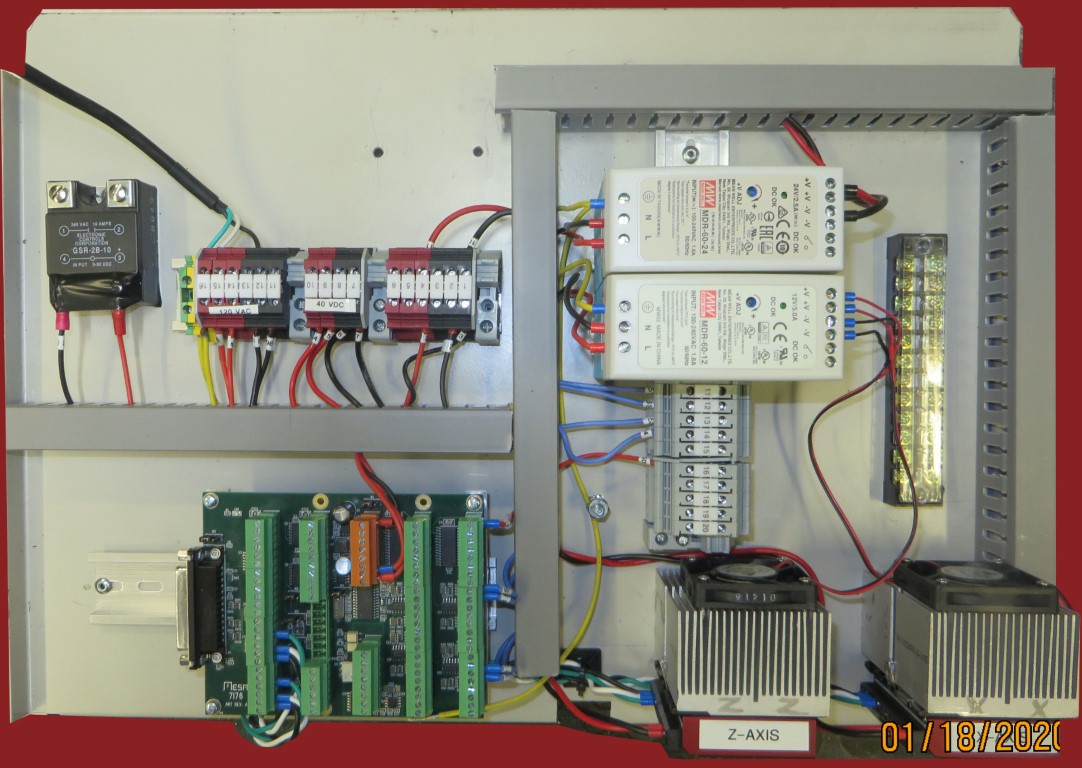

Random Update

Today I managed to get all the new parts, wires, etc all into one location and after a few backsteps and a spindle VFD wiring confusion (Sorted out thanks to PCW) I now have....

Movement in X and Z axis, both directions

Z limit and home working and back installed

X limit and home working (but not installed, really need to change the way I had the switch mounted so maybe now is the time)

remote E-stop switch working

Spindle speed and direction kind of working (RPM is way off, haven't done anything with the gear ranges yet but it spins up and down and reverses

Still waiting on new gears for the spindle encoder and I'll mount something temp in the mean time.

Need to tidy up the wiring a bunch as they are just loosely run over from the bulkhead fittings but I wanted to fire everything up before going nuts with the zip ties

Anyway, with all the various help from all the various people.... movement!!!

Next up, getting the spindle gears/rpm dialed in and maybe the encoder at the same time (would make it easier than using the laser tach on the pulleys...)

M

Today I managed to get all the new parts, wires, etc all into one location and after a few backsteps and a spindle VFD wiring confusion (Sorted out thanks to PCW) I now have....

Movement in X and Z axis, both directions

Z limit and home working and back installed

X limit and home working (but not installed, really need to change the way I had the switch mounted so maybe now is the time)

remote E-stop switch working

Spindle speed and direction kind of working (RPM is way off, haven't done anything with the gear ranges yet but it spins up and down and reverses

Still waiting on new gears for the spindle encoder and I'll mount something temp in the mean time.

Need to tidy up the wiring a bunch as they are just loosely run over from the bulkhead fittings but I wanted to fire everything up before going nuts with the zip ties

Anyway, with all the various help from all the various people.... movement!!!

Next up, getting the spindle gears/rpm dialed in and maybe the encoder at the same time (would make it easier than using the laser tach on the pulleys...)

M

Attachments:

Last edit: 20 Jan 2020 01:11 by mooser.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Starting from scratch (again) - need help (apparently a lot)

Time to create page: 0.179 seconds