writing chip conveyor component , user input wanted

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

23 Feb 2024 12:51 #294075

by smc.collins

writing chip conveyor component , user input wanted was created by smc.collins

I am writing a conveyor component, it'll have some basic features, a sensor input to see if the conveyor is moving, estop out, washdown turn on output , after spindle off feature and a few other little basic items. Anyone think of any other features that would be nice to have ? what prompted this, my conveyor jammed while i was letting the machine run un-attened, the motor performed a spectacular smoke show.

basic configuration

Spindle enable start conveyor

Hall effect sensor is a deadman switch that is reset every time the trigger passes by the sensor " chain whell in my case"

After run timer, to run conveyor after the spindle is turned off " to clear chip bed and hal adjustable"

Washdown output with timer " setup a washdown pump and chip wash system " to clear swarf around the machine enclosure

Estop output or error notification system " notify of malfunction stop machine is required or turn on red light on cabinet"

Auto reversing and stoping, run motor in rever with 2nd contactor or reverse the dc drive controller etc, and stop conveyor to help unjam

are there any features I am missing ?

basic configuration

Spindle enable start conveyor

Hall effect sensor is a deadman switch that is reset every time the trigger passes by the sensor " chain whell in my case"

After run timer, to run conveyor after the spindle is turned off " to clear chip bed and hal adjustable"

Washdown output with timer " setup a washdown pump and chip wash system " to clear swarf around the machine enclosure

Estop output or error notification system " notify of malfunction stop machine is required or turn on red light on cabinet"

Auto reversing and stoping, run motor in rever with 2nd contactor or reverse the dc drive controller etc, and stop conveyor to help unjam

are there any features I am missing ?

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

23 Feb 2024 14:24 #294077

by scotth

Replied by scotth on topic writing chip conveyor component , user input wanted

For the cost of a reversing contactor you could almost install a cheap VFD. You get better current control, speed control and easy reversal.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

23 Feb 2024 15:24 #294080

by spumco

Maybe something like:

Replied by spumco on topic writing chip conveyor component , user input wanted

Couldn't tell from your explanation, but having an adjustable run on/off timer would be nice.

are there any features I am missing ?

Maybe something like:

- Mode 1

- On with spindle on, off-delay when spindle off

- M100.1 FWD

- M100.2 REV

- OFF at M101 or M5

- Mode 2

- On-off repeating cycle while spindle on, off-delay when spindle off

- i.e. set to come on for X seconds every M2/M30 or 2 minutes or some other frequency

- Saves wear on the conveyor. I have small parts that don't need constant chip clearing, but still need periodic dumping

- M100.1 Px Qx (P-on time, Q-off time)

- Mode 3

- Manual FWD/REV/OFF override

- No M-code needed, just straight pushbutton activation.

- Useful if you're standing there and timing how long it takes to clear chips per cycle, or just need to clear some out while it's running a program

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

23 Feb 2024 16:07 #294085

by scotth

Replied by scotth on topic writing chip conveyor component , user input wanted

Other advantages are reduced start current and less coolant drag out at reduced speed. Look at the "The Laws of Fans and Pumps" for power reduction by reducing speed. A VFD will give a pretty good payback.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

23 Feb 2024 16:21 #294086

by spumco

I think you may be confusing the OP's intentions here. He's writing a (mostly) hardware-agnostic software component to manage conveyor control, not retrofitting hardware to a conveyor.

Aside from possibly incorporating speed control in his software component, the VFD vs contactors thing is a non-issue at this point.

Replied by spumco on topic writing chip conveyor component , user input wanted

@scotth,Other advantages are reduced start current and less coolant drag out at reduced speed. Look at the "The Laws of Fans and Pumps" for power reduction by reducing speed. A VFD will give a pretty good payback.

I think you may be confusing the OP's intentions here. He's writing a (mostly) hardware-agnostic software component to manage conveyor control, not retrofitting hardware to a conveyor.

Aside from possibly incorporating speed control in his software component, the VFD vs contactors thing is a non-issue at this point.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

23 Feb 2024 16:41 #294087

by tommylight

Replied by tommylight on topic writing chip conveyor component , user input wanted

Adding a VFD "can" not change anything, set the speed manually and use it just as run fwd/rev, so the component sees it as two relays.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

23 Feb 2024 19:23 #294105

by chris@cnc

One interval function is nice to have. Reduced the coolant drag out.

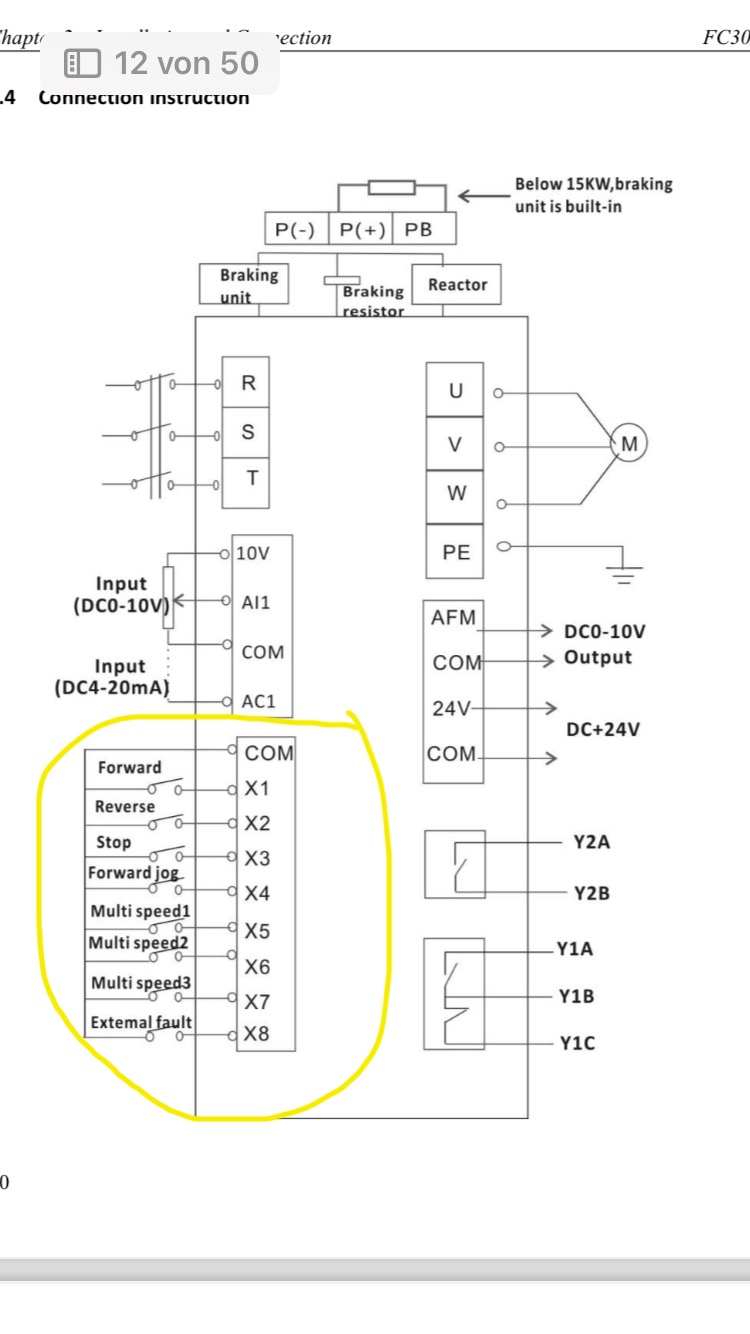

I don't think so. VFD is an intelligent device. Usually you have three single inputs and could select motor speed over there and have a current control.

Replied by chris@cnc on topic writing chip conveyor component , user input wanted

are there any features I am missing ?

One interval function is nice to have. Reduced the coolant drag out.

Adding a VFD "can" not change anything, set the speed manually and use it just as run fwd/rev, so the component sees it as two relays.

I don't think so. VFD is an intelligent device. Usually you have three single inputs and could select motor speed over there and have a current control.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

23 Feb 2024 21:13 #294118

by tommylight

All VFD i have worked with can be set to be controlled just by fwd/rev pins, at whatever speed you set them on the VFD panel.

You seem to be thinking of the option on some VFD's to also choose a preset speed, but that is not a feature on all VFD's.

Replied by tommylight on topic writing chip conveyor component , user input wanted

Adding a VFD "can" not change anything, set the speed manually and use it just as run fwd/rev, so the component sees it as two relays.

I don't think so. VFD is an intelligent device. Usually you have three single inputs and could select motor speed over there and have a current control.

All VFD i have worked with can be set to be controlled just by fwd/rev pins, at whatever speed you set them on the VFD panel.

You seem to be thinking of the option on some VFD's to also choose a preset speed, but that is not a feature on all VFD's.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21271

- Thank you received: 7262

23 Feb 2024 21:18 #294119

by tommylight

Replied by tommylight on topic writing chip conveyor component , user input wanted

Reading this again, i really hope you are not thinking about the analog control inputs with 3 wires and 0-10V or 0-5V or 0-20mA ???I don't think so. VFD is an intelligent device. Usually you have three single inputs and could select motor speed over there and have a current control.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

23 Feb 2024 21:59 - 23 Feb 2024 22:01 #294125

by chris@cnc

Replied by chris@cnc on topic writing chip conveyor component , user input wanted

Attachments:

Last edit: 23 Feb 2024 22:01 by chris@cnc.

Please Log in or Create an account to join the conversation.

Time to create page: 0.108 seconds