Servo Tune Newbie

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Oct 2013 22:57 #40418

by DaOne

Servo Tune Newbie was created by DaOne

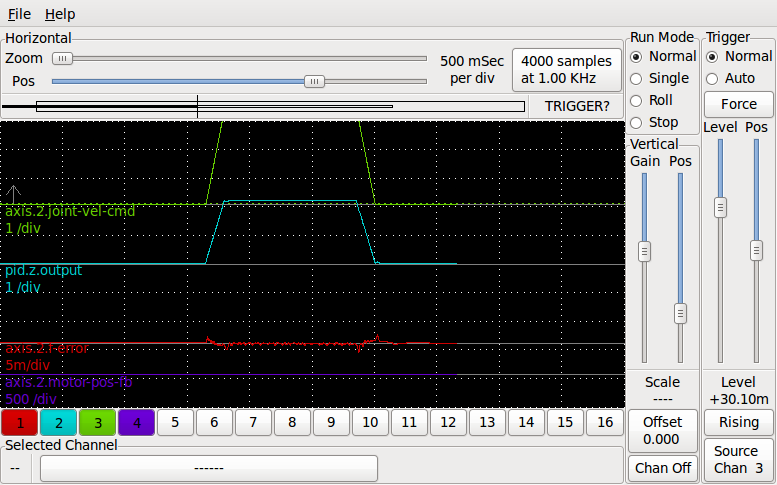

This is my first attempt at tuning a velocity servo loop. I feel it could be better but unsure what direction to take on settings. I mostly followed this tutorial: gnipsel.com/linuxcnc/tuning/servo.html. Are there any other ones to look at? Anyways here are the details...

Drive is an old Fanuc with DC (perm magnet) Gettys motor Model 20

Screw pitch is 10mm

P 40

I 0.065

D 0.001

Bias 0

FF0 0.001

FF1 0.625

FF2 0.0015

Deadband 0.00004

Drive is an old Fanuc with DC (perm magnet) Gettys motor Model 20

Screw pitch is 10mm

P 40

I 0.065

D 0.001

Bias 0

FF0 0.001

FF1 0.625

FF2 0.0015

Deadband 0.00004

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

30 Oct 2013 23:25 #40420

by andypugh

Replied by andypugh on topic Servo Tune Newbie

Is this a metric or an Imperial machine?

Your worst-case following-error looks to be about 1 milli-unit. So that is either 1 micron (really pretty good) or 1 thousandth (less good, but not awful during what would be (in that case) a 200 in/min move.

Your worst-case following-error looks to be about 1 milli-unit. So that is either 1 micron (really pretty good) or 1 thousandth (less good, but not awful during what would be (in that case) a 200 in/min move.

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Oct 2013 23:28 #40421

by DaOne

Replied by DaOne on topic Servo Tune Newbie

It is a imperial machine. Any tips for getting it better?

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Oct 2013 23:33 #40422

by DaOne

Replied by DaOne on topic Servo Tune Newbie

I calculated my encoder resolution at 0.0000393701in for a 10mm pitch screw on a 2500 quadrature encoder. Maybe you can check to see if my math is correct? Should I be using this number as the deadband or up it a little as I did?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

30 Oct 2013 23:38 #40423

by andypugh

0.001" f-error during a rapid isn't horrible. What is the f-error during a cutting-speed move?

Replied by andypugh on topic Servo Tune Newbie

It is a imperial machine. Any tips for getting it better?

0.001" f-error during a rapid isn't horrible. What is the f-error during a cutting-speed move?

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Oct 2013 23:40 #40424

by DaOne

Replied by DaOne on topic Servo Tune Newbie

I will test and report back. Any specific speed you want me to try? Say 20ipm good? Or slower?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

30 Oct 2013 23:40 #40425

by andypugh

I get the same number, assuming it is 2500-slots for 10,000 counts.

Replied by andypugh on topic Servo Tune Newbie

I calculated my encoder resolution at 0.0000393701in for a 10mm pitch screw on a 2500 quadrature encoder. Maybe you can check to see if my math is correct?

I get the same number, assuming it is 2500-slots for 10,000 counts.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

30 Oct 2013 23:43 #40427

by andypugh

I don't know what is typical. I am still re-calibrating away from my mini-mill where 20mm/min was about as much as it could do. I still get nervous when I program a 100mm/min cut (4 in/min)

Maybe a more experienced imperial machinist can suggest a sensible number.

Replied by andypugh on topic Servo Tune Newbie

I will test and report back. Any specific speed you want me to try? Say 20ipm good? Or slower?

I don't know what is typical. I am still re-calibrating away from my mini-mill where 20mm/min was about as much as it could do. I still get nervous when I program a 100mm/min cut (4 in/min)

Maybe a more experienced imperial machinist can suggest a sensible number.

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Oct 2013 23:46 #40428

by DaOne

Yes that's correct 10,000 counts. Thank you for checking my math. Should I use that as my deadband number? Also I noticed that before I adjusted the "I" value all of my moves were exactly 1 thousandth off in the positive direction. putting in some "I" helped with that problem.

Should I use that as my deadband number? Also I noticed that before I adjusted the "I" value all of my moves were exactly 1 thousandth off in the positive direction. putting in some "I" helped with that problem.

Replied by DaOne on topic Servo Tune Newbie

I calculated my encoder resolution at 0.0000393701in for a 10mm pitch screw on a 2500 quadrature encoder. Maybe you can check to see if my math is correct?

I get the same number, assuming it is 2500-slots for 10,000 counts.

Yes that's correct 10,000 counts. Thank you for checking my math.

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Oct 2013 23:48 #40429

by DaOne

I will post the scope screens with a few different cut speeds then for you to look at. Heading over to the shop now.

Replied by DaOne on topic Servo Tune Newbie

I will test and report back. Any specific speed you want me to try? Say 20ipm good? Or slower?

I don't know what is typical. I am still re-calibrating away from my mini-mill where 20mm/min was about as much as it could do. I still get nervous when I program a 100mm/min cut (4 in/min)

Maybe a more experienced imperial machinist can suggest a sensible number.

I will post the scope screens with a few different cut speeds then for you to look at. Heading over to the shop now.

Please Log in or Create an account to join the conversation.

Time to create page: 0.087 seconds