Effect of FF1 varies with feed rate?

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 4

03 Apr 2017 17:42 #90805

by jCandlish

Effect of FF1 varies with feed rate? was created by jCandlish

After emprically setting [JOINT_n]OUTPUT_SCALE such that FF1=1.0 was well compensated I found that changes of the feed speed effect the compensation.

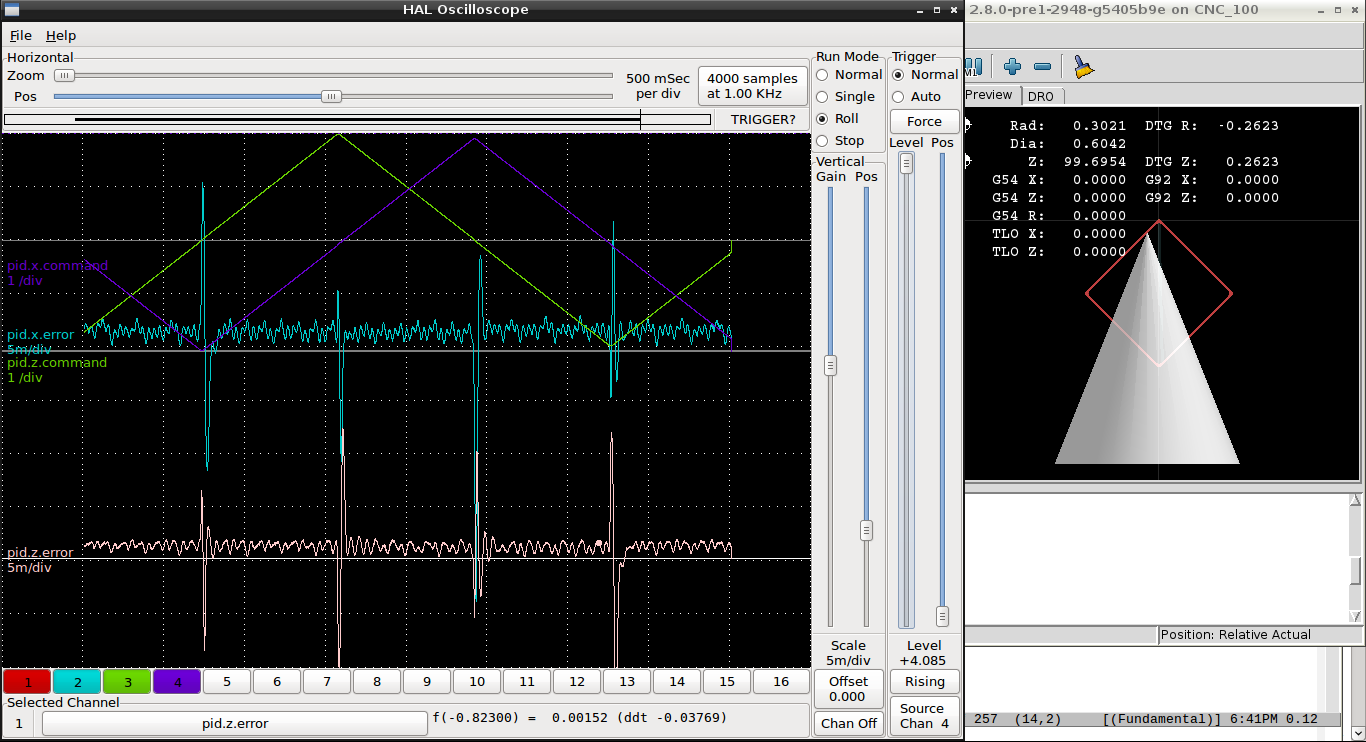

For f200 (metric) FF1=1.0 gave good compensation:

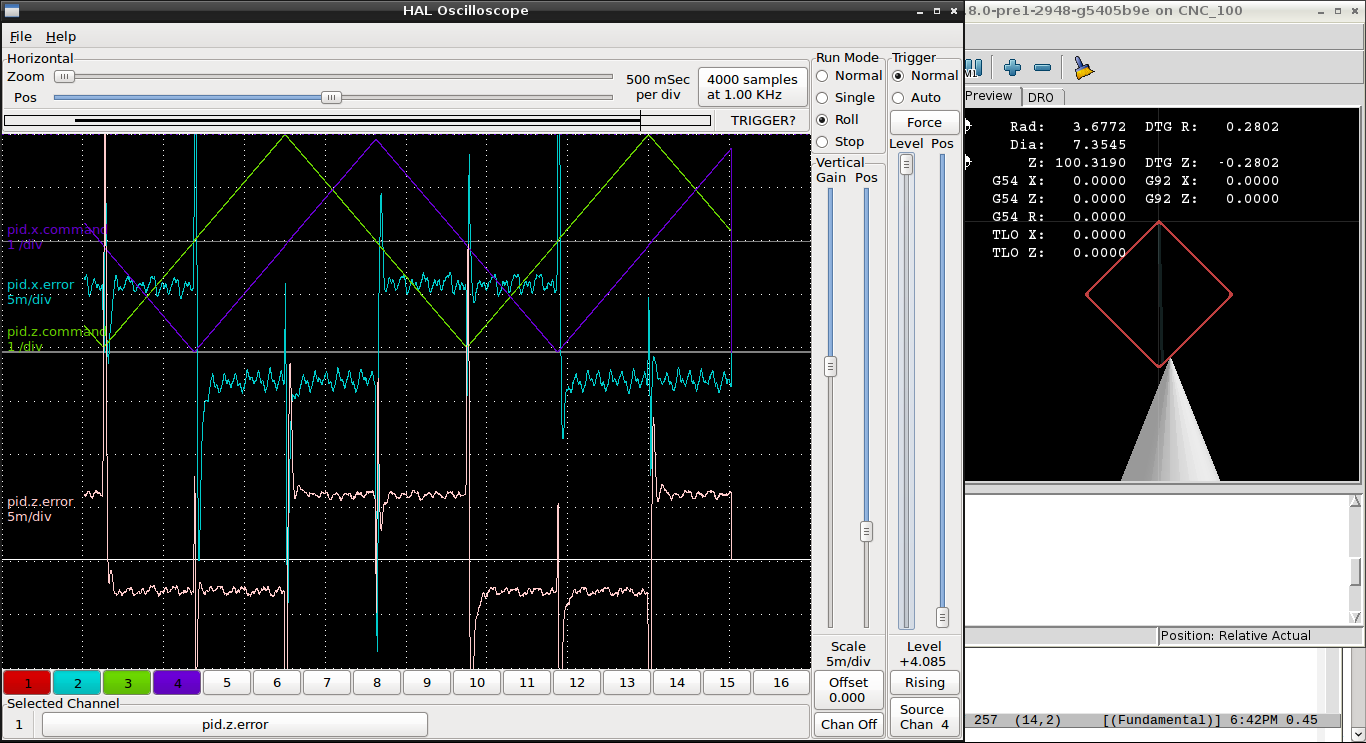

At f350 the compensation is not so good:

I assume the cause is non-linear response of OUTPUT_SCALE to different commanded speeds, or is this the expected behavior?

For f200 (metric) FF1=1.0 gave good compensation:

At f350 the compensation is not so good:

I assume the cause is non-linear response of OUTPUT_SCALE to different commanded speeds, or is this the expected behavior?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17603

- Thank you received: 5147

03 Apr 2017 18:05 #90807

by PCW

Replied by PCW on topic Effect of FF1 varies with feed rate?

The nonlinearity is more likely in the PID output path somewhere

(not in LinuxCNC)

(not in LinuxCNC)

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21176

- Thank you received: 7235

03 Apr 2017 18:06 #90809

by tommylight

Replied by tommylight on topic Effect of FF1 varies with feed rate?

forum.linuxcnc.org/10-advanced-configura...-how-to?limitstart=0

If you read the above thread, it is explicitly mentioned that ff1 will change with any change to other parameters. It has to be set at low feeds and gradualy calibrated with higher and higher feed rates, only after the scale and P factor had been set.

If i remember correctly, for the FF1 to be 1 there are several other parameters that need to have the needed value. From your post i think that you did exactly that, but if it changes with feed, something is not quite as it should be.

I can not dwel into more detail as there are way more qualified members on this forum for that.

Regards,

Tom

If you read the above thread, it is explicitly mentioned that ff1 will change with any change to other parameters. It has to be set at low feeds and gradualy calibrated with higher and higher feed rates, only after the scale and P factor had been set.

If i remember correctly, for the FF1 to be 1 there are several other parameters that need to have the needed value. From your post i think that you did exactly that, but if it changes with feed, something is not quite as it should be.

I can not dwel into more detail as there are way more qualified members on this forum for that.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 4

03 Apr 2017 18:23 #90812

by jCandlish

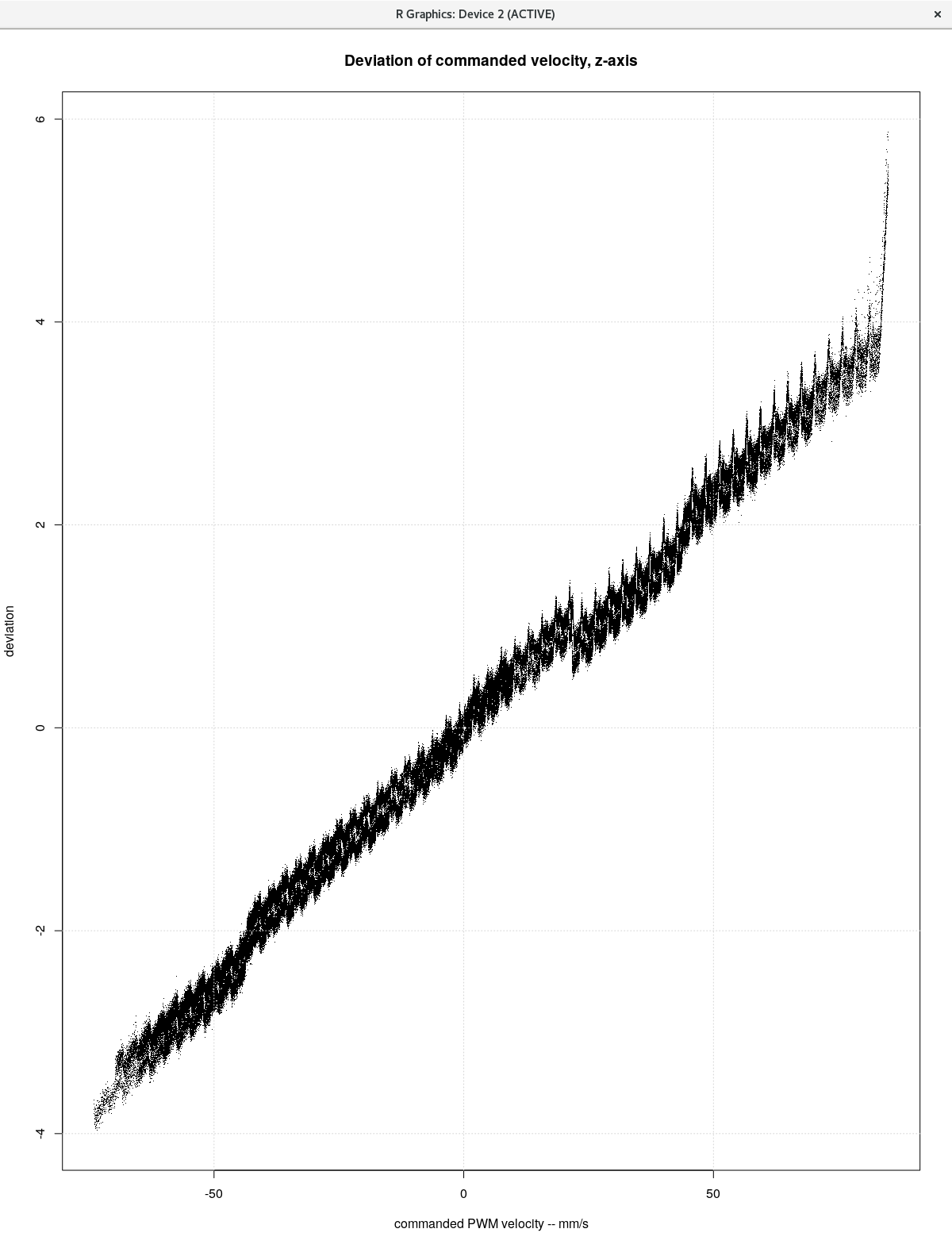

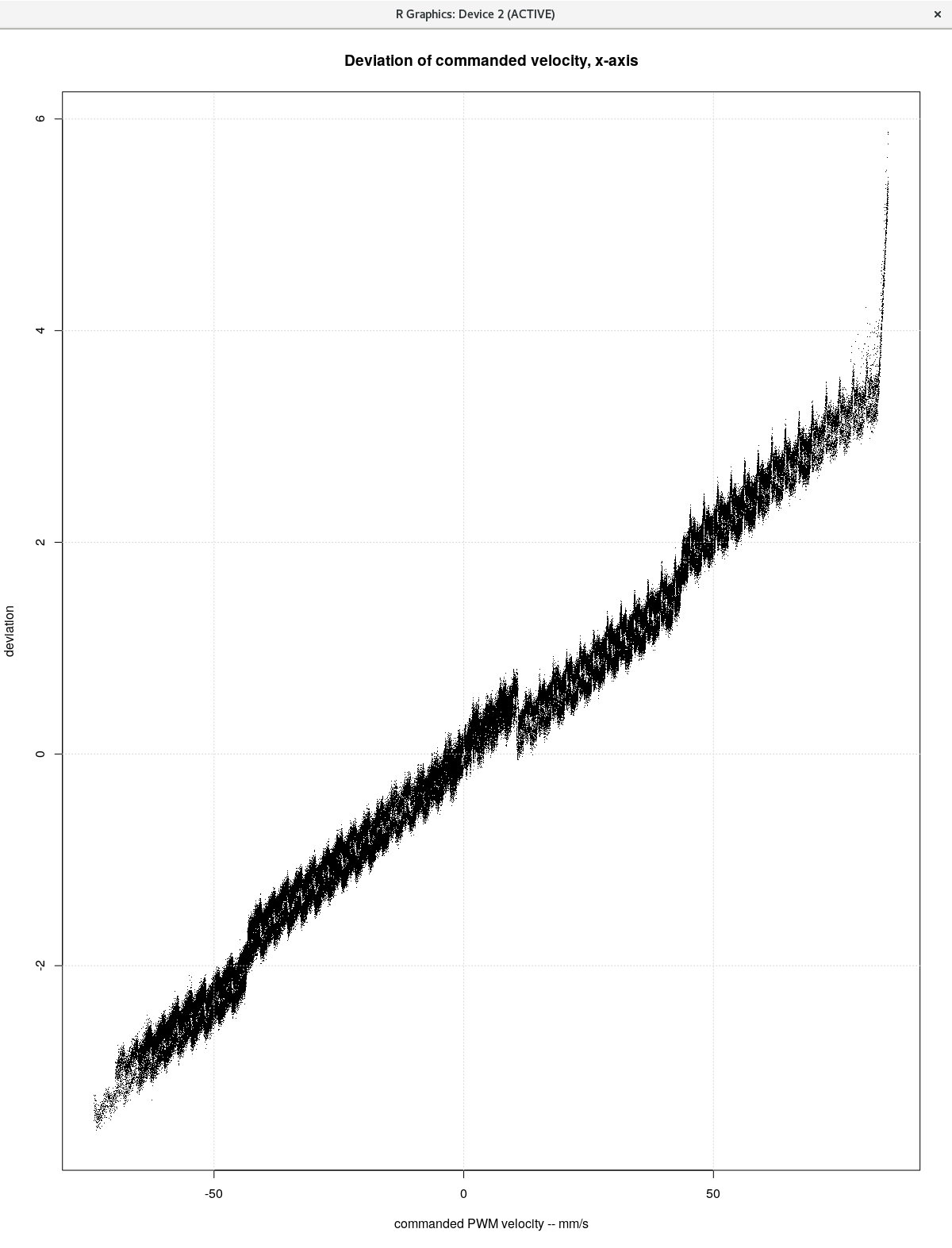

I think the non-linearity is the servo response to the analog voltage signal. I am just mapping that now.

Does there already exist a look-up-table that can be applied to correct for the amplifiers response curve?

Replied by jCandlish on topic Effect of FF1 varies with feed rate?

The nonlinearity is more likely in the PID output path somewhere

(not in LinuxCNC)

I think the non-linearity is the servo response to the analog voltage signal. I am just mapping that now.

Does there already exist a look-up-table that can be applied to correct for the amplifiers response curve?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17603

- Thank you received: 5147

03 Apr 2017 18:59 #90813

by PCW

Replied by PCW on topic Effect of FF1 varies with feed rate?

Yes, the lincurve component is designed for this kind of thing

Please Log in or Create an account to join the conversation.

- jCandlish

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 4

04 Apr 2017 07:06 #90853

by jCandlish

Replied by jCandlish on topic Effect of FF1 varies with feed rate?

Please Log in or Create an account to join the conversation.

Time to create page: 0.128 seconds