Lathe tool changer turret - DC motor based

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 50

27 Sep 2017 10:47 #99514

by pippin88

Lathe tool changer turret - DC motor based was created by pippin88

I'm retrofitting a small CNC lathe (Hercus PC200) and I need some pointers on getting the turret going with Linuxcnc.

It's an 8 position tool turret driven by a DC gearmotor.

When the motor is rotating forward, the turret rotates.

There is a position sensor for each tool position (actually a single NC switch with a dimple causing switch trip near each tool position)

There is an index sensor (NC switch).

To lock, the motor is reversed, this drives 3 locking pins backwards. These have to line up with a plate which holes in it. The pins hit a plate when fully out, completing a circuit (locking sensor).

(Thus the turret can only rotate in one direction)

So it's a similar turret to many others that use a rotate then reverse onto a pawl. The difference is that the locking requires the locking pins to line up with the lock holes. The pins do have a taper on them to deal with some misalignment.

So far:

I have all the sensors detected in linuxcnc (index, locking, position).

I have a L298N H bridge driving the motor.

I have outputs from my 7i43 setup, such that I can turn the motor forward or reverse (0 0 = off, 1 0 = forward, 0 1 = reverse, 1 1 = off).

Difficulties:

The position switch does not line up exactly with where the tool should actually be and thus where the locking holes are. The turret will need to rotate a set distance or time past the position sensed point before the motor can reverse and lock.

I've been reading the documentation / forums and there are a number of ways to approach this:

Classicladder.

Adapt a user component.

Write a new component.

Can someone point me towards which would be the best starting point? I have a basic working understanding of LinuxCNC / hal, but no programming background.

Many thanks.

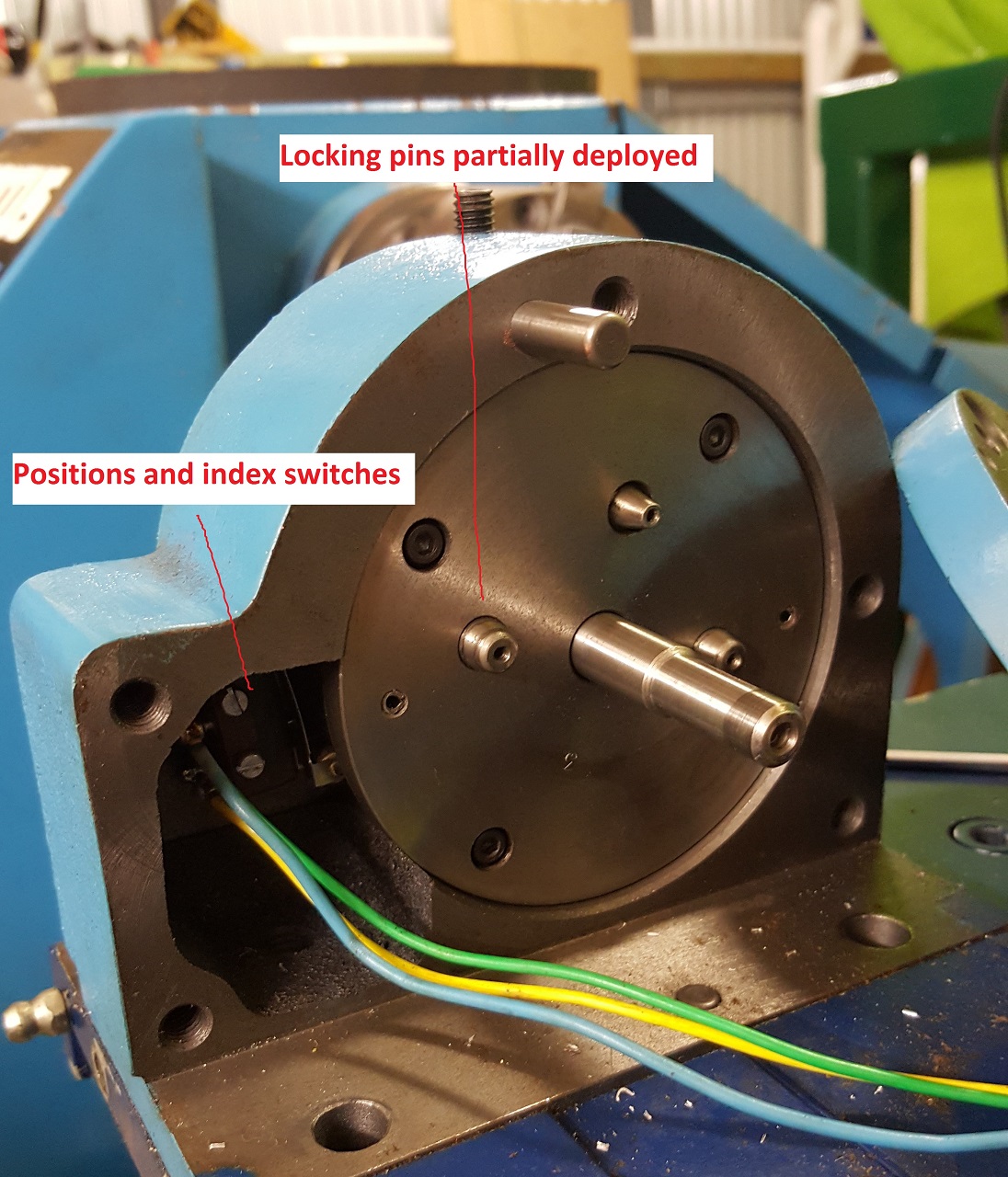

Locking plate/holes - behind the plate is a brass plate with a wire connected. The plate is otherwise isolated until the pins touch it.

Locking pins partially deployed

It's an 8 position tool turret driven by a DC gearmotor.

When the motor is rotating forward, the turret rotates.

There is a position sensor for each tool position (actually a single NC switch with a dimple causing switch trip near each tool position)

There is an index sensor (NC switch).

To lock, the motor is reversed, this drives 3 locking pins backwards. These have to line up with a plate which holes in it. The pins hit a plate when fully out, completing a circuit (locking sensor).

(Thus the turret can only rotate in one direction)

So it's a similar turret to many others that use a rotate then reverse onto a pawl. The difference is that the locking requires the locking pins to line up with the lock holes. The pins do have a taper on them to deal with some misalignment.

So far:

I have all the sensors detected in linuxcnc (index, locking, position).

I have a L298N H bridge driving the motor.

I have outputs from my 7i43 setup, such that I can turn the motor forward or reverse (0 0 = off, 1 0 = forward, 0 1 = reverse, 1 1 = off).

Difficulties:

The position switch does not line up exactly with where the tool should actually be and thus where the locking holes are. The turret will need to rotate a set distance or time past the position sensed point before the motor can reverse and lock.

I've been reading the documentation / forums and there are a number of ways to approach this:

Classicladder.

Adapt a user component.

Write a new component.

Can someone point me towards which would be the best starting point? I have a basic working understanding of LinuxCNC / hal, but no programming background.

Many thanks.

Locking plate/holes - behind the plate is a brass plate with a wire connected. The plate is otherwise isolated until the pins touch it.

Locking pins partially deployed

Please Log in or Create an account to join the conversation.

- johnmc1

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 21

27 Sep 2017 13:32 #99518

by johnmc1

Replied by johnmc1 on topic Lathe tool changer turret - DC motor based

Good day,

Why is the centre pin tapered, maybe it is has something to do with helping centre the lock pins?

john

Why is the centre pin tapered, maybe it is has something to do with helping centre the lock pins?

john

Please Log in or Create an account to join the conversation.

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 50

27 Sep 2017 20:34 #99528

by pippin88

Replied by pippin88 on topic Lathe tool changer turret - DC motor based

John,

It may be for that reason. That pin seems to come further out and appears to be the one that makes contact with the brass plate.

It may be for that reason. That pin seems to come further out and appears to be the one that makes contact with the brass plate.

Please Log in or Create an account to join the conversation.

- johnmc1

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 21

28 Sep 2017 07:06 #99540

by johnmc1

Replied by johnmc1 on topic Lathe tool changer turret - DC motor based

Good Day

Some of the hercus lathes were fitted with ANCA 2000 controllers that used resolver feed back on the servo motors.

Was your hercus fitted with a ANCA controller and what controller system are you going to use with your refit?

I have a hercus computurn lathe fitted with a anca controller that one day I will refit.

john

Some of the hercus lathes were fitted with ANCA 2000 controllers that used resolver feed back on the servo motors.

Was your hercus fitted with a ANCA controller and what controller system are you going to use with your refit?

I have a hercus computurn lathe fitted with a anca controller that one day I will refit.

john

Please Log in or Create an account to join the conversation.

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 50

28 Sep 2017 07:27 #99541

by pippin88

Replied by pippin88 on topic Lathe tool changer turret - DC motor based

John,

I believe mine was a DOS machine but did not come with the computer. The servos had encoders and what I think are tachometers.

I've removed the original electronics and motors.

For X and Z I'm using 381oz.in steppers driven by Leadshine DM856 drivers. Motion controller is LinuxCNC and Mesa 7i43 with 7i76.

Spindle will be a largish servo.

I believe mine was a DOS machine but did not come with the computer. The servos had encoders and what I think are tachometers.

I've removed the original electronics and motors.

For X and Z I'm using 381oz.in steppers driven by Leadshine DM856 drivers. Motion controller is LinuxCNC and Mesa 7i43 with 7i76.

Spindle will be a largish servo.

Please Log in or Create an account to join the conversation.

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 50

30 Sep 2017 12:29 #99676

by pippin88

Replied by pippin88 on topic Lathe tool changer turret - DC motor based

I had not realised how the hal component system worked. Based on the excellent contributions of ArcEye (wiki.linuxcnc.org/cgi-bin/wiki.pl?ContributedComponents), I think I have something resembling a working component for my tool changer.

This is purely tested in simulation, but works as expected when I use a PYVCP to simulate the sensor inputs. I will have to work out the timing to get the locking right.

This is purely tested in simulation, but works as expected when I use a PYVCP to simulate the sensor inputs. I will have to work out the timing to get the locking right.

/*************************************************************************************************************************************

LinuxCNC HAL component to implement ATC toolchanging on Hercus PC200 Lathe

Based on "EMC2 HAL component to implement ATC toolchanging in Denford ORAC CNC lathes" (c) ArcEye 01122011 schooner30@tiscali.co.uk

Modified by pippin88 - 30/09/2017

All values are metric

Version 0a - The PC200 toolchanger has an 8 position unidirectional turret. There is an index sensor (PC200changer.index),

and a position sensor (PC200changer.pocket) that pulses once per tool position.

When the motor moves forwards, the turret rotates. When the motor is reveresed, locking pins deploy, interfacing with a locking disc.

When the locking pins are fully deployed, they close a circuit (PC200changer.lock)

The sensors do not line up exactly with the actual tool position, but are a set offset.

To allow the ATC time to get past the sensor and line the locking pins up with the holes, a timedelay component

is used with the on-delay set to X seconds.

This is activated automatically by the PC200changer component with the hal connections shown below.

The turret uses a simple DC motor. This is driven by an H-bridge (L298N) which takes two input signals to determine direction.

motor A and motor B. A HIGH, B HIGH = motor off; A HIGH, B LOW = motor forward; A LOW, B HIGH = motor reverse; A LOW, B LOW = motor off;

I use A HIGH, B HIGH for off, as this is less susceptible to noise than a resting LOW state.

To cater for the delay in mechanical relays switching the motor on and off and forward and reverse, and to allow the motor

itself to cease movement, there is a simple counter delay in the component.

The period of this delay is set by default to 500, which equates to 1-2 secs on my test system

It can be modified in the .hal file using

'setp PC200changer.times nnn' where nnn is the new value

Compile the components with 'sudo comp --install PC200changer.comp'

and 'sudo comp --install timedelay2.comp' respectively

Below .hal file extracts give a specimen .hal connection guide. Place them as appropriate in .hal file

###############################################################

# loading the toolchange and timedelay2 components in .hal file

###############################################################

loadrt PC200changer

addf PC200changer servo-thread

#loadrt timedelay count=1

#addf timedelay.0 servo-thread

### will wait 5 secs approx

#setp timedelay.0.on-delay 5

net tool-change iocontrol.0.tool-change => PC200changer.toolchange

net tool-changed iocontrol.0.tool-changed <= PC200changer.toolchanged

net tool-number iocontrol.0.tool-prep-number => PC200changer.toolnumber

net tool-oldnumber iocontrol.0.tool-number => PC200changer.currenttoolnumber

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net turret-lock PC200changer.lock <= hm2_7i43.0.7i76.0.0.input-25 #Turret Lock sensor (White)

net turret-index PC200changer.index <= hm2_7i43.0.7i76.0.0.input-26 #Turret Index (Green)

net turret-position PC200changer.pocket <= hm2_7i43.0.7i76.0.0.input-27 #Turret Pulse (Blue)

## GPIO33 = Turret motorA

setp hm2_7i43.0.gpio.033.is_output true

setp hm2_7i43.0.gpio.033.out true ### pull high at startup!!! Can change if needed

## GPIO34 = Turret motorB

setp hm2_7i43.0.gpio.034.is_output true

setp hm2_7i43.0.gpio.034.out true ### pull high at startup!!! Can change if needed

net turret-motorA PC200changer.motorA => hm2_7i43.0.gpio.033.out

net turret-motorB PC200changer.motorB => hm2_7i43.0.gpio.034.out

net xhomed axis.0.homed => PC200changer.ishomedX

net zhomed axis.2.homed => PC200changer.ishomedZ

setp PC200changer.times nnn ### where nnn is the new value

#net delaystart timedelay.0.in <= PC200changer.delaystart

#net delaydone timedelay.0.out => PC200changer.delaydone

################################################################################

***************************************************************************************************************************************/

component PC200changer "This component controls the PC200 Lathe Auto Tool Changer. M6 calls this";

pin in bit toolchange "Receives signal from M6 that tool change required";

pin in s32 reqtoolnumber "Requested Tool Number - Tx data from M6. Only 1-8 allowed";

pin in s32 currenttoolnumber "Receives old tool number from hal / axis";

pin out bit toolchanged = false "Sends signal when tool change finished";

pin out bit delaystart = false "Starts timerdelay";

pin in bit delaydone =false "Signals timer finished";

pin in bit index = 1 "State of turret index sensor";

pin in bit pocket = 1 "State of turret pocket sensor";

pin in bit lock = 1 "State of turret lock sensor";

pin out bit motorA = 1 "Motor signal A";

pin out bit motorB = 1 "Motor signal B";

pin in bit ishomedX = false "Status of X axis homing";

pin in bit ishomedZ = false "Status of Z axis homing";

pin out s32 position = 0 "Turret Position - Initialised as a pin for debugging so we can check where it thinks it is";

pin out s32 turrethomed = 0 "Turret Homed signal - Initialised as a pin for debugging so we can check where it thinks it is";

param rw float times = 5000 "Length of delay for forward move before locking";

// Internal and debugging stuff

pin out s32 progresslevel = 0; // tracks the progress of the toolchange, just here so it can be read easily

pin out s32 tnumber = 0; // Internal toolnumber to allow overrun of quadrant by 1 then reverse back onto it

variable bool bWarn = false; // first toolnumber reminder

variable float sleeptime = 0; // our own timer to set delay for locking - set to 0 for first run

variable int indexState = 1; // current state of the index signal - for rising edge

variable int lastindexState = 1; // previous state of the index signal - for rising edge

variable int pocketState = 1; // current state of the pocket signal - for rising edge

variable int lastpocketState = 1; // previous state of the pocket signal - for rising edge

variable int lockState = 1; // current state of the pocket signal - for rising edge

variable int lastlockState = 1; // previous state of the pocket signal - for rising edge

option singleton yes; // makes no sense to have more than one of these components running - only one ATC

function _;

author "pippin88 pippin88@imagineant.com";

license "GPL";

;;

FUNCTION(_)

{

switch (progresslevel)

{

case 0: // idle waiting for toolchange request

//first make sure X and Z axes are homed. If turret is not homed, home it

if((toolchange==1)&&(turrethomed==0)&&(ishomedX)&&(ishomedZ)){

progresslevel = 1; //call case 1 - homing sequence

break;

}

if(toolchange==1 && toolchanged==0 && turrethomed==1) { // if tool change requested and not done and turret already homed

if(currenttoolnumber && reqtoolnumber != currenttoolnumber && reqtoolnumber > 0 && reqtoolnumber < 9) { // if a valid number

// switch off motor if already on - both pins high = stop

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

//delaystart = false; //new toolchange - reset comp

sleeptime = 0;

progresslevel = 2; //call case 2

break;

}

else // if tool requested is out of range set the toolchanged flag via case 5 and exit

// should only get this if tool table has more tools than ATC can have

// otherwise emc will error the M6 command

{

progresslevel = 5;

// switch off motor if already on - both pins high = stop

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

}

}

if(toolchange==0 && toolchanged==1)

//Turn motor OFF

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

toolchanged = false; // reset toolchange flag after reset by linuxcnc

if(toolchange && currenttoolnumber==0) // if no tool is set in axis - set axis to tool requested so that can work next time

{

// switch off motor if already on

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

progresslevel = 5;

}

break;

case 1: // homing

motorA = 0; // "Motor input A"; //need to check direction!!!!

motorB = 1; // "Motor input B";

// use a state machine to detect the index pulse only once

indexState = index; // read the pocket sensor input pin

if (lastindexState != indexState) { // compare the pocketState to its previous state

if (index == 1) { // if the current state is HIGH then the index went from off to on - RISING EDGE

//motorA = 1;

//motorB = 1;

position = 1; //Set Tool Pocket 1

turrethomed = 1; //Set turrent homed flag

progresslevel = 2; //move to motor forward sequence

}

}

lastindexState = indexState; //store indexState for comparison next time around

break; // index not triggered - get out of case 1 and go round again

case 2: // Turns on motor forward

// Run forward - need to clarify pins etc

motorA = 0; // "Motor input A";

motorB = 1; // "Motor input B";

progresslevel = 3;

break; //get out of case 2 - - go round again

case 3: // Forward move until desired tool position

if(position==0) // if returning 0 something is wrong - should be homed and at pocket 1 at least

{

rtapi_print_msg(RTAPI_MSG_ERR, "Error - counter error");

progresslevel = 12; // doesn't exist so will go to default, output msg and then sit in level 10

break;

}

//use a state machine to detect pocket sensor once per position only

pocketState = pocket; // read the pocket sensor input pin

if (lastpocketState != pocketState) { // compare the pocketState to its previous state

if (pocket == 1) { // if the state has changed, increment the counter

// if the current state is HIGH then the button went from off to on - RISING EDGE

position++;

if(position > 8) // add 1 so that stops on sector after required & reverses back to it

position = position - 8;

}

}

lastpocketState = pocketState; // save the current state as the last state, for next time through the loop

sleeptime = 0; //reset counter to 0

//delaystart = true; //signal to linuxcnc there will be a delay

if (position == reqtoolnumber) {

progresslevel = 4; //move to case 3

}

break; //get out of case 2 - go round again

case 4: // Locking sequence

// programmed delay to allow time to align with locking holes

if(sleeptime < times)

{

sleeptime++;

break;

}

// Reverse locking move - need to clarify pins etc

motorA = 1; // "Motor input A";

motorB = 0; // "Motor input B";

//use a state machine to detect lock sensor once only - detect falling edge

lockState = lock; // read the pocket sensor input pin

if (lastlockState != lockState) { // compare the pocketState to its previous state

if (lock == 0) { // if the state has changed, increment the counter

// if the current state is LOW then the lock circuit has grounded

//Turn motor OFF

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

progresslevel = 5; // after first toolchange or update of tool number this is default

}

}

lastlockState = lockState; // save the current state as the last state, for next time through the loop

break; //get out of case 3 - go round again

case 5: // clean up ready for next toolchange

//delaystart = true; // start the 5 second delay relay component to give time to latch

progresslevel = 0;

//delaystart=false;

toolchanged = true; // signal finished

break; //get out of case 5 - go round again

case 10: break; // should never get here but if we do then loop endlessly doing nothing

default:

progresslevel = 10;

rtapi_print_msg(RTAPI_MSG_ERR, "Error state in PC200changer - now disabled - unload PC200changer");

break;

}

}

The following user(s) said Thank You: johnmc1

Please Log in or Create an account to join the conversation.

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 50

07 Oct 2017 03:28 - 19 Oct 2017 21:31 #100032

by pippin88

Replied by pippin88 on topic Lathe tool changer turret - DC motor based

Below code works on my machine. Slightly different approach from code posted earlier, as I worked out a bit more about how the turret works mechanically and under the old controller.

/*************************************************************************************************************************************

LinuxCNC HAL component to implement ATC toolchanging on Hercus PC200 Lathe

Based on "EMC2 HAL component to implement ATC toolchanging in Denford ORAC CNC lathes" (c) ArcEye 01122011 schooner30@tiscali.co.uk

Modified by pippin88 - 07/10/2017

All values are metric

Version 0c - The PC200 toolchanger has an 8 position unidirectional turret. There is an index sensor (PC200changer.index),

and a position sensor (PC200changer.pocket) that pulses once per tool position.

When the motor moves forwards, the turret rotates forward.

The position sensor does not line up exactly with the actual tool position, but is past the tool position a bit

- the turret reverses until the spring-loaded pins line up and jump into the locking holes.

When the locking pins are fully deployed, they close a circuit (PC200changer.lock)

The turret uses a simple DC motor. This is driven by an H-bridge (L298N) which takes two input signals to determine direction.

motor A and motor B. A HIGH, B HIGH = motor off; A HIGH, B LOW = motor forward; A LOW, B HIGH = motor reverse; A LOW, B LOW = motor off;

I use A HIGH, B HIGH for off, as this is less susceptible to noise than a resting LOW state.

Compile the component with 'sudo comp --install PC200changer.comp'

Below .hal file extracts give a specimen .hal connection guide. Place them as appropriate in .hal file

###############################################################

# loading the toolchange component in .hal file

###############################################################

loadrt PC200changer

addf PC200changer servo-thread

net tool-change iocontrol.0.tool-change => PC200changer.toolchange

net tool-changed iocontrol.0.tool-changed <= PC200changer.toolchanged

net tool-number iocontrol.0.tool-prep-number => PC200changer.reqtoolnumber

net tool-oldnumber iocontrol.0.tool-number => PC200changer.currenttoolnumber

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net turret-lock PC200changer.lock <= hm2_7i43.0.7i76.0.0.input-25 #Turret Lock sensor (White)

net turret-index PC200changer.index <= hm2_7i43.0.7i76.0.0.input-26 #Turret Index (Green)

net turret-pocket PC200changer.pocket <= hm2_7i43.0.7i76.0.0.input-27 #Turret Pulse (Blue)

## GPIO33 = Turret motorA

setp hm2_7i43.0.gpio.033.is_output true

setp hm2_7i43.0.gpio.033.out true ### pull high at startup!!! Can change if needed

## GPIO34 = Turret motorB

setp hm2_7i43.0.gpio.034.is_output true

setp hm2_7i43.0.gpio.034.out true ### pull high at startup!!! Can change if needed

net turret-motorA PC200changer.motorA => hm2_7i43.0.gpio.033.out

net turret-motorB PC200changer.motorB => hm2_7i43.0.gpio.034.out

net xhomed joint.0.homed => PC200changer.ishomedX

net zhomed joint.1.homed => PC200changer.ishomedZ

#setp PC200changer.times 125 ### where nnn is the new value - sets a sleep timer

################################################################################

***************************************************************************************************************************************/

component PC200changer "This component controls the PC200 Lathe Auto Tool Changer. M6 calls this";

pin in bit toolchange "Receives signal from M6 that tool change required";

pin in s32 reqtoolnumber "Requested Tool Number - Tx data from M6. Only 1-8 allowed";

pin in s32 currenttoolnumber "Receives old tool number from hal / axis";

pin out bit toolchanged = false "Sends signal when tool change finished";

pin in bit index = 1 "State of turret index sensor";

pin in bit pocket = 1 "State of turret pocket sensor";

pin in bit lock = 1 "State of turret lock sensor";

pin out bit motorA = 1 "Motor signal A";

pin out bit motorB = 1 "Motor signal B";

pin in bit ishomedX = false "Status of X axis homing";

pin in bit ishomedZ = false "Status of Z axis homing";

pin out s32 turretposition = 0 "Turret Position - Initialised as a pin for debugging so we can check where it thinks it is";

pin out s32 turrethomed = 0 "Turret Homed signal - Initialised as a pin for debugging so we can check where it thinks it is";

param rw float times = 290 "Length of delay";

// Internal and debugging stuff

pin out s32 progresslevel = 0; // tracks the progress of the toolchange, just here so it can be read easily

//pin out s32 tnumber = 0; // Internal toolnumber to allow overrun of quadrant by 1 then reverse back onto it

variable bool bWarn = false; // first toolnumber reminder

variable float sleeptime = 0; // our own timer to set delay for locking - set to 0 for first run

pin out bit indexState = 1; // current state of the index signal - for rising edge

pin out bit lastindexState = 1; // previous state of the index signal - for rising edge

pin out bit unlockState = 1; // current state of the index signal - for rising edge

pin out bit lastunlockState = 1; // previous state of the index signal - for rising edge

pin out bit pocketState = 1; // current state of the pocket signal - for rising edge

pin out bit lastpocketState = 1; // previous state of the pocket signal - for rising edge

pin out bit lockState = 1; // current state of the pocket signal - lock is detected on falling edge

pin out bit lastlockState = 1; // previous state of the pocket signal

pin out bit turretislocked = 0;

option singleton yes; // makes no sense to have more than one of these components running - only one ATC

function _;

author "pippin88 pippin88@imagineant.com";

license "GPL";

;;

FUNCTION(_)

{

switch (progresslevel) {

case 0: // idle waiting for toolchange request

//first make sure X and Z axes are homed. If turret is not homed, home it

if((toolchange==1)&&(turrethomed==0)&&(ishomedX)&&(ishomedZ)){

progresslevel = 1; //call case 1 - homing sequence

break;

}

if((toolchange==1)&&(toolchanged==0)&&(turrethomed==1)) { // if tool change requested and not done and turret already homed

if(currenttoolnumber && reqtoolnumber != currenttoolnumber && reqtoolnumber > 0 && reqtoolnumber < 9) { // if a valid number

// switch off motor if already on - both pins high = stop

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

//sleeptime = 0;

progresslevel = 2; //call case 2

break;

}

else // if tool requested is out of range set the toolchanged flag via case 5 and exit

// should only get this if tool table has more tools than ATC can have

// otherwise emc will error the M6 command

{

progresslevel = 5;

// switch off motor if already on - both pins high = stop

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

}

}

if(!toolchange) {

//Turn motor OFF

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

toolchanged = 0; // reset toolchange flag after reset by linuxcnc

}

//if(toolchange && currenttoolnumber==0) // if no tool is set in axis - set axis to tool requested so that can work next time

// {

// switch off motor if already on

// motorA = 1; // "Motor input A";

// motorB = 1; // "Motor input B";

// progresslevel = 5;

// }

break;

case 1: // HOMING SEQUENCE

// Turn motor forward

motorA = 0; // "Motor input A";

motorB = 1; // "Motor input B";

// use a state machine to detect the index pulse only once

indexState = index; // read the index sensor input pin

if (lastindexState != indexState) { // compare the indexState to its previous state

if (index == 0) { // if the current state is LOW then the index went from ON to OFF - FALLING EDGE

turretposition = 8; //Set Tool Pocket 1

turrethomed = 1; //Set turrent homed flag

if (reqtoolnumber == 8){

progresslevel = 4; //move to locking sequence

} else {

progresslevel = 2; //move to motor forward sequence

}

}

}

lastindexState = indexState; //store indexState for comparison next time around

break; // index not triggered - get out of case 1 and go round again

case 2: // UNLOCKING - use first pocket pulse to show that turret unlocked, and to prevent that first pulse counting as a position increment

// Run forward - need to clarify pins etc

motorA = 0; // "Motor input A";

motorB = 1; // "Motor input B";

//use a state machine to detect pocket sensor

unlockState = pocket; // read the pocket sensor input pin

if (lastunlockState != unlockState) { // compare the pocketState to its previous state

if (pocket == 1) { // if the current state is HIGH then the button went from OFF to ON - RISING EDGE

progresslevel = 3;

}

}

lastunlockState = unlockState; // save the current state as the last state, for next time through the loop

break; //get out of case 2 - - go round again

case 3: // FORWARD TOOL FIND SEQUENCE - Forward move until desired tool position

motorA = 0; // "Motor input A";

motorB = 1; // "Motor input B";

if(turretposition==0) { // if returning 0 something is wrong - should be homed and at pocket 1 at least

rtapi_print_msg(RTAPI_MSG_ERR, "Error - counter error");

progresslevel = 12; // doesn't exist so will go to default, output msg and then sit in level 10

break;

}

//use a state machine to detect pocket sensor once per position only

pocketState = pocket; // read the pocket sensor input pin

if (lastpocketState != pocketState) { // compare the pocketState to its previous state

if (pocket == 0) { // if the state has changed, increment the counter

// if the current state is LOW then the button went from ON to OFF - FALLING EDGE

turretposition++; //increment tool position counter

if(turretposition > 8)

turretposition = turretposition - 8; //we have gone round from 8 to 1

}

}

lastpocketState = pocketState; // save the current state as the last state, for next time through the loop

if (turretposition == reqtoolnumber) {

progresslevel = 4; //move to case 4

}

break; //get out of case 3 - go round again

case 4: // LOCKING SEQUENCE

// Reverse locking move

motorA = 1; // "Motor input A";

motorB = 0; // "Motor input B";

//use a state machine to detect lock sensor once only - detect falling edge

lockState = lock; // read the pocket sensor input pin

if (lastlockState != lockState) { // compare the pocketState to its previous state

if (lock == 0) { // if the state has changed, increment the counter

// if the current state is LOW then the lock circuit has grounded

//Turn motor OFF

motorA = 1; // "Motor input A";

motorB = 1; // "Motor input B";

turretislocked = 1;

progresslevel = 5;

}

}

lastlockState = lockState; // save the current state as the last state, for next time through the loop

break; //get out of case 4 - go round again

case 5: // clean up ready for next toolchange

//sleeptime = 0;

progresslevel = 6;

toolchanged = 1; // signal finished

break; //get out of case 5 - go round again

case 6:

//if(sleeptime < 1)

//{

// sleeptime++;

// break;

//}

progresslevel = 0;

break;

case 10: break; // should never get here but if we do then loop endlessly doing nothing

default:

progresslevel = 10;

rtapi_print_msg(RTAPI_MSG_ERR, "Error state in PC200changer - now disabled - unload PC200changer");

break;

}

}

Last edit: 19 Oct 2017 21:31 by pippin88.

Please Log in or Create an account to join the conversation.

- AndrewL

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 2

07 Apr 2020 14:49 #163064

by AndrewL

Replied by AndrewL on topic Lathe tool changer turret - DC motor based

I am interested in using the code you've posted on turret tool changer using a hydraulic motor, position sensor, and a lock pin. How do I use what you have written for my configuration?

I do not know how to use the .comp

I see this line in your code:

Compile the component with 'sudo comp --install PC200changer.comp'

But I don't know how to use it and if I try it in the command line I get a 'comp: command not found'. Is this something that will only work on a development version of linuxcnc or can I incorporate it into what I have (2.7.14)?

I do not know how to use the .comp

I see this line in your code:

Compile the component with 'sudo comp --install PC200changer.comp'

But I don't know how to use it and if I try it in the command line I get a 'comp: command not found'. Is this something that will only work on a development version of linuxcnc or can I incorporate it into what I have (2.7.14)?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20964

- Thank you received: 7144

07 Apr 2020 22:38 #163110

by tommylight

Replied by tommylight on topic Lathe tool changer turret - DC motor based

It does require development version installed, easy to do using synaptics, seems you have a Wheezy installation.

And the command comp is now halcompile, so just replace that when installing the component.

And the command comp is now halcompile, so just replace that when installing the component.

Please Log in or Create an account to join the conversation.

- AndrewL

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 2

08 Apr 2020 02:12 #163145

by AndrewL

Replied by AndrewL on topic Lathe tool changer turret - DC motor based

Thank you. Yes I have a Wheezy uspace install. Is wheezy 2.8-rtpreempt the one I'll need?

Please Log in or Create an account to join the conversation.

Time to create page: 0.125 seconds