Fusion 360 CAM and linuxcnc touch off

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

21 Feb 2018 07:23 - 21 Feb 2018 07:42 #106271

by Desertboy

Fusion 360 CAM and linuxcnc touch off was created by Desertboy

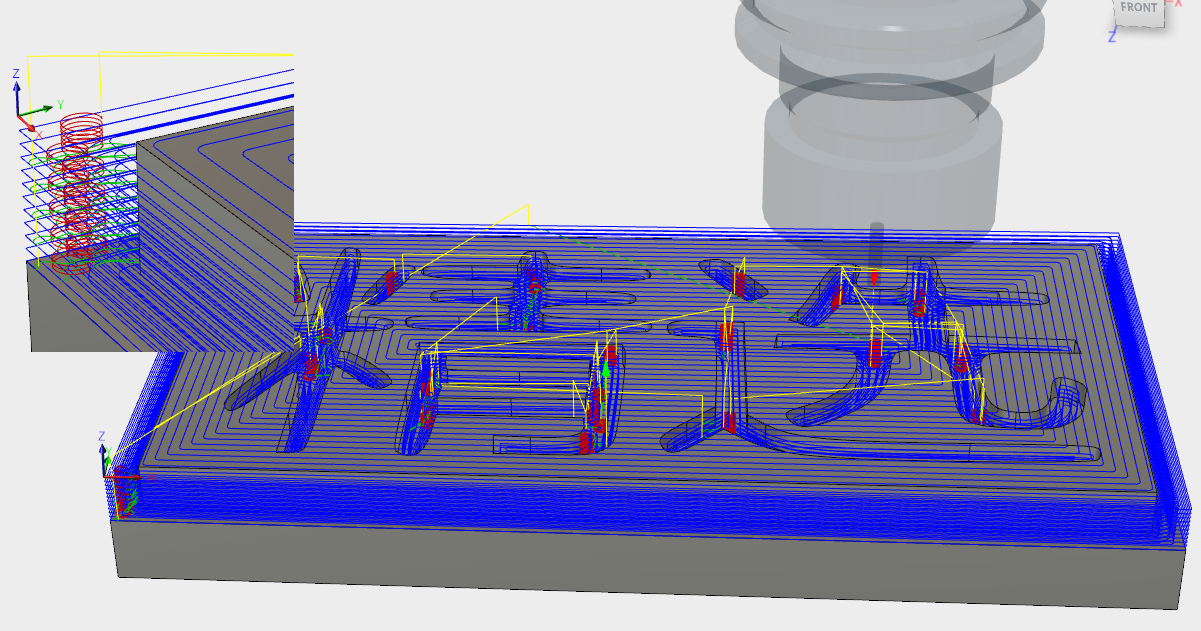

Hi, I'm just trying to understand touching off (I'm touching off in software), no touch probe.

Hopefully I've set 0,0,0 to the bottom left corner in the picture, do I then touch off X,Y & Z to 0,0,0 ( assuming I have moved the spindle to the bottom left of the piece.

Also tool touch off I notice that until it's loaded a tool it's greyed out they when a tool is loaded it's not, what does it do?

Thanks

Hopefully I've set 0,0,0 to the bottom left corner in the picture, do I then touch off X,Y & Z to 0,0,0 ( assuming I have moved the spindle to the bottom left of the piece.

Also tool touch off I notice that until it's loaded a tool it's greyed out they when a tool is loaded it's not, what does it do?

Thanks

Last edit: 21 Feb 2018 07:42 by Desertboy.

Please Log in or Create an account to join the conversation.

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

21 Feb 2018 13:11 - 21 Feb 2018 13:12 #106274

by Desertboy

Replied by Desertboy on topic Fusion 360 CAM and linuxcnc touch off

Solved, I was homing the Z when I had it at 0, the first move fusion makes is a retract which fired a Z axis limit message.

Still unsure about tool touch off is this for when you do a tool change?

Still unsure about tool touch off is this for when you do a tool change?

Last edit: 21 Feb 2018 13:12 by Desertboy.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4686

- Thank you received: 1433

21 Feb 2018 13:29 #106275

by Todd Zuercher

Replied by Todd Zuercher on topic Fusion 360 CAM and linuxcnc touch off

Normally homing is used to set Z=0 for the base machine coordinate system (usually at the top of Z travel). This is a basic reference point. The base machine coordinates are not normally used for actual milling. Then work coordinates systems (G54,G55... work offsets) are used to move the Z=0 to the point needed for actually running your G-code. This is how Z=0 (and/or X or Y...) is moved to the to the top or bottom of your part you need to mill according to how you have your G-code configured. That process is done by using the Touch Off button or G10 commands. This can be used for tool changes, but usually that is done by tool offsets. It can also be used for setting up multiple fixture positions or what ever other uses you can dream up.

Please Log in or Create an account to join the conversation.

Time to create page: 0.117 seconds