A question of Scale.....

- racedirector

- Offline

- Elite Member

-

Less

More

- Posts: 231

- Thank you received: 42

24 Feb 2019 11:56 #127047

by racedirector

A question of Scale..... was created by racedirector

Hi All

I have been wondering lately how accurate we have to be when setting the Scale for our machines.

I want my machine to be as accurate as possible so I have been using a scale with 14 decimal points. I have no idea if this detail is actually required so here I am.

On my machine I have Module 1 racks, 4:1 reduction, 30 tooth pinions powered by 640 OzIn Nema 34 Steppers. My controllers are AM882's powered by a 70V Toroidal power system set to 8 Microstepping. Also in the mix is a Mesa 5i25 and 7I76. My current software is PathPilot 2.14. The machine itself has a working area of 2400x1200.

With that knowledge just how accurate can I be? Would I need smaller pinions (I have a bunch of 24 tooth available if needed)?

This is my current Scale setting for all axis: -1725.81113657584232 It is negative because non-negative goes backwards, yes I probably have the drives all wrong but this was the easiest way to fix.

Anyone have any input on the accuracy expectations versus Scale setting?

Cheers

Bruce

I have been wondering lately how accurate we have to be when setting the Scale for our machines.

I want my machine to be as accurate as possible so I have been using a scale with 14 decimal points. I have no idea if this detail is actually required so here I am.

On my machine I have Module 1 racks, 4:1 reduction, 30 tooth pinions powered by 640 OzIn Nema 34 Steppers. My controllers are AM882's powered by a 70V Toroidal power system set to 8 Microstepping. Also in the mix is a Mesa 5i25 and 7I76. My current software is PathPilot 2.14. The machine itself has a working area of 2400x1200.

With that knowledge just how accurate can I be? Would I need smaller pinions (I have a bunch of 24 tooth available if needed)?

This is my current Scale setting for all axis: -1725.81113657584232 It is negative because non-negative goes backwards, yes I probably have the drives all wrong but this was the easiest way to fix.

Anyone have any input on the accuracy expectations versus Scale setting?

Cheers

Bruce

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

24 Feb 2019 14:31 #127054

by Leon82

Replied by Leon82 on topic A question of Scale.....

You need a known length like a long stack of gauge blocks. Indicate the face of one side and set zero.

Then rapid to the other end and check that face. Go the same direction so backlash isn't a factor.

Then rapid to the other end and check that face. Go the same direction so backlash isn't a factor.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17531

- Thank you received: 5125

24 Feb 2019 14:41 #127055

by PCW

Replied by PCW on topic A question of Scale.....

Accuracy has many components, on a 2400 mm steel table for example you would have a ~.3 mm shift at the end of travel with a 10C temperature change. Even 6 digits of scale setting is way beyond what is typically needed.

I would expect backlash, stiction, expansion with temperature, and flex to be the major

contributions to position errors

Have you measured the backlash/repeatability with an indicator?

I would expect backlash, stiction, expansion with temperature, and flex to be the major

contributions to position errors

Have you measured the backlash/repeatability with an indicator?

Please Log in or Create an account to join the conversation.

- Richard J Kinch

-

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 4

25 Feb 2019 09:05 #127092

by Richard J Kinch

Theory: The choice of scale value determines the digital granularity (steps per motor revolution) of control, because scale is defined as the inverse of granularity per turn. Choose that control granularity to be upper-limited "some fraction" of the total mechanical imprecision (a statistical, analog "granularity" if you will) following the motor, and lower-limited by the speed goal of the motor vs the available bandwidth of the control signal (how fast you want the top speed of the motor to go, divided by how fast you can step). "Some fraction" is at most the Nyquist criterion of 0.5, but often pessimistically taken as 0.1. This is a "weakest link" analysis, similar to how in circuit theory, parallel resistor networks have to be calculated as the inverse of the sum of the inverses.

For example, if the mechanism (im)precision is 0.001in, then you want steps certainly no larger than 0.0005in (by Nyquist), or no larger than 0.0001in (by cautious pessimism). Finer steps that these will not yield any precision-performance benefit, and compete against the speed-performance imposed by stepping bandwidth. Larger steps than these will lose control of physical precision. This is an "impedance matching" analysis, similar to how in circuit theory, impedance governs the efficiency of power transfer.

Choose the step size with all that in mind, then divide the travel per turn of the motor by that step size, and that's the scale value. To continue the example, if you are a pessimist and choose 0.0001in granularity, and if the motor turns translate into 0.1in of motion, then the scale value is 1000 = 0.1in/0.0001in. Competing with that will be the step-rate bandwidth and speed goal; if the step bandwidth is 10 kHz, then the speed will be limited to 0.1in/sec = 10000 Hz * 0.0001in.

Replied by Richard J Kinch on topic A question of Scale.....

Anyone have any input on the accuracy expectations versus Scale setting?

Theory: The choice of scale value determines the digital granularity (steps per motor revolution) of control, because scale is defined as the inverse of granularity per turn. Choose that control granularity to be upper-limited "some fraction" of the total mechanical imprecision (a statistical, analog "granularity" if you will) following the motor, and lower-limited by the speed goal of the motor vs the available bandwidth of the control signal (how fast you want the top speed of the motor to go, divided by how fast you can step). "Some fraction" is at most the Nyquist criterion of 0.5, but often pessimistically taken as 0.1. This is a "weakest link" analysis, similar to how in circuit theory, parallel resistor networks have to be calculated as the inverse of the sum of the inverses.

For example, if the mechanism (im)precision is 0.001in, then you want steps certainly no larger than 0.0005in (by Nyquist), or no larger than 0.0001in (by cautious pessimism). Finer steps that these will not yield any precision-performance benefit, and compete against the speed-performance imposed by stepping bandwidth. Larger steps than these will lose control of physical precision. This is an "impedance matching" analysis, similar to how in circuit theory, impedance governs the efficiency of power transfer.

Choose the step size with all that in mind, then divide the travel per turn of the motor by that step size, and that's the scale value. To continue the example, if you are a pessimist and choose 0.0001in granularity, and if the motor turns translate into 0.1in of motion, then the scale value is 1000 = 0.1in/0.0001in. Competing with that will be the step-rate bandwidth and speed goal; if the step bandwidth is 10 kHz, then the speed will be limited to 0.1in/sec = 10000 Hz * 0.0001in.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

25 Feb 2019 10:23 #127094

by pl7i92

Replied by pl7i92 on topic A question of Scale.....

Theory Verses Praxis

Best Scale vs Precision vs Speed vs Torque vs Budget

In Europ SORRY ballscrew 1605 means 5mm/revelution)

Steppers 200steps / rev // TIMED 400 -800 1600...

as on a Timingbelt 20/25 teeth it means 1,25 Gear Ratio you are with Halfstepping at

BEST Speed ,Best Precision , Max Torque

Best Speed means 0,01mm (0,00039in) Per step the MAX Speed you can go saying 12000mm/min or 500IPM as off 100000 Latency

Best Precision 0,01mm (0,00039in) Per step the Min Your Messurment system takes CALIBER

MAX Torque as of Halfstepping brings the Best of your Power to Stepeper (( 10Times the Stepper Voltige Rate Requirerd 5V/48V )

soy your Hardware shoudt be optimised

NOT the DIP Switch of the DRIVER

to get BEST

Best Scale vs Precision vs Speed vs Torque vs Budget

In Europ SORRY ballscrew 1605 means 5mm/revelution)

Steppers 200steps / rev // TIMED 400 -800 1600...

as on a Timingbelt 20/25 teeth it means 1,25 Gear Ratio you are with Halfstepping at

BEST Speed ,Best Precision , Max Torque

Best Speed means 0,01mm (0,00039in) Per step the MAX Speed you can go saying 12000mm/min or 500IPM as off 100000 Latency

Best Precision 0,01mm (0,00039in) Per step the Min Your Messurment system takes CALIBER

MAX Torque as of Halfstepping brings the Best of your Power to Stepeper (( 10Times the Stepper Voltige Rate Requirerd 5V/48V )

soy your Hardware shoudt be optimised

NOT the DIP Switch of the DRIVER

to get BEST

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11582

- Thank you received: 3896

25 Feb 2019 11:16 #127099

by rodw

Replied by rodw on topic A question of Scale.....

I'm not a machinist but as Racedirector is a fellow Aussie it would be well worth his while getting your hands on the "Engineers Black Book" by Sutton Tools and review the tolerance tables for shafts and holes. The tightest seems to be a H6 code which is 0.000 to -0.006 on shafts 1-3mm in diameter. But when you get up to 18-30mm shafts, the same H6 tolerance is 0.000 to 0.013.

Remember that a micron is 0.001 mm . A human hair is about 75 microns wide and the finest merino wools are around 16 microns. A red blood cell is about 5 microns wide.

So then you need to ask yourself would a smear of blood only one cell thick affect your engineering outcome? Could you run your fingers over this in the dark and feel it? Would your bloodied shaft no longer fit ? I suspect not.

So if we can only comprehend a measurement up to 0.001 mm, If your device units are millimetres 14 decimal places is a bit overkill when in our climate a steel table can vary 1mm in length from winter to summer.

Remember that a micron is 0.001 mm . A human hair is about 75 microns wide and the finest merino wools are around 16 microns. A red blood cell is about 5 microns wide.

So then you need to ask yourself would a smear of blood only one cell thick affect your engineering outcome? Could you run your fingers over this in the dark and feel it? Would your bloodied shaft no longer fit ? I suspect not.

So if we can only comprehend a measurement up to 0.001 mm, If your device units are millimetres 14 decimal places is a bit overkill when in our climate a steel table can vary 1mm in length from winter to summer.

Please Log in or Create an account to join the conversation.

- racedirector

- Offline

- Elite Member

-

Less

More

- Posts: 231

- Thank you received: 42

25 Feb 2019 11:30 - 25 Feb 2019 11:33 #127100

by racedirector

Replied by racedirector on topic A question of Scale.....

Thanks everyone, it looks like I have opened a rather large can of worms!

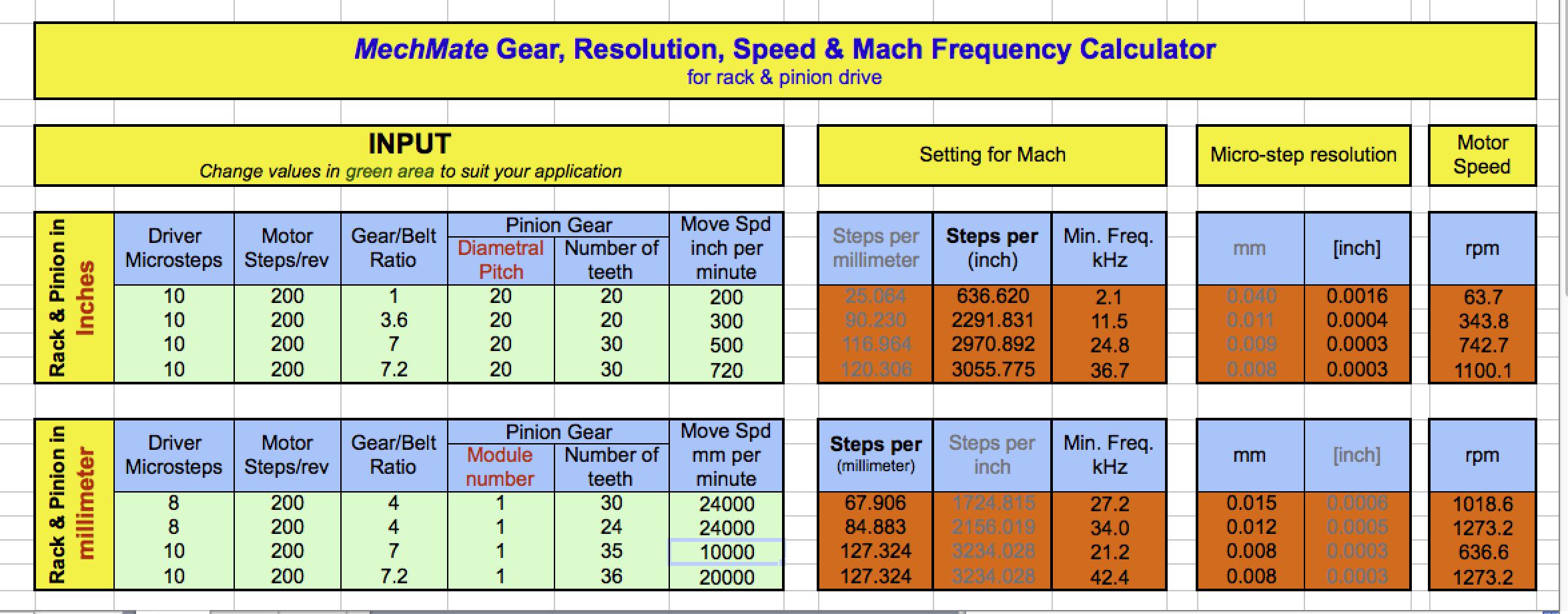

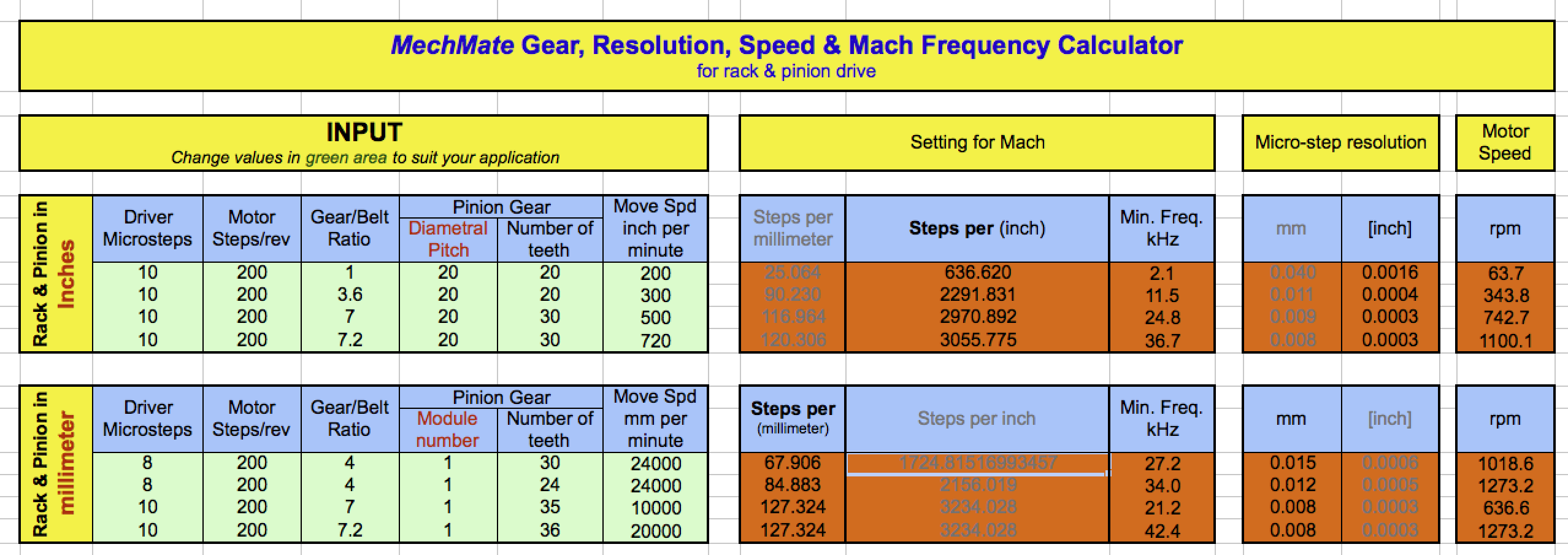

I feel my original post was badly worded, I was purely after the information of wether my 14 decimal places made a difference to Linuxcnc. Now I asked that because I use a spreadsheet designed by the original maker of my machine and that spreadsheet was targeted at Mach3. I have no idea (and could care less) if Mach3 can use anything but 3 decimal points in calculations of scale or steps per inch.

Here is a screenshot of the sheet with my 2 scenarios in the metric part of the sheet. The first 1 is default with 3 decimal points in the calc.

this second shot is the same but the value has been expanded to 11 decimal points.

Not wildly different, just accuracy in the calculation.

I know my self built machine is not going to be as accurate as a Haas for example, mine is for wood not metal etc etc. I was just looking for a definitive answer if LCNC could use any more than 3 or even no decimal points at all.

Rod, my machine has grabbed my t-shirt at stages, scared the hell out of me. I know I could feel the bloody thing rolling over fleshy bits if they got in the way!!

Cheers

I feel my original post was badly worded, I was purely after the information of wether my 14 decimal places made a difference to Linuxcnc. Now I asked that because I use a spreadsheet designed by the original maker of my machine and that spreadsheet was targeted at Mach3. I have no idea (and could care less) if Mach3 can use anything but 3 decimal points in calculations of scale or steps per inch.

Here is a screenshot of the sheet with my 2 scenarios in the metric part of the sheet. The first 1 is default with 3 decimal points in the calc.

this second shot is the same but the value has been expanded to 11 decimal points.

Not wildly different, just accuracy in the calculation.

I know my self built machine is not going to be as accurate as a Haas for example, mine is for wood not metal etc etc. I was just looking for a definitive answer if LCNC could use any more than 3 or even no decimal points at all.

Rod, my machine has grabbed my t-shirt at stages, scared the hell out of me. I know I could feel the bloody thing rolling over fleshy bits if they got in the way!!

Cheers

Last edit: 25 Feb 2019 11:33 by racedirector.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11582

- Thank you received: 3896

25 Feb 2019 12:49 #127102

by rodw

Replied by rodw on topic A question of Scale.....

I only meant for you to feel the 5 micron coating, not feel it tear through your flesh! I tried that and it isn't much fun!

PHOTO EVIDENCE DELETED

PHOTO EVIDENCE DELETED

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

25 Feb 2019 13:57 #127106

by pl7i92

Replied by pl7i92 on topic A question of Scale.....

That high Microstepping kills all your Performence but ads allot of Issues to your machine

10 Microsteps as Fixed on the G540 Whow

10 Microsteps as Fixed on the G540 Whow

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21110

- Thank you received: 7210

25 Feb 2019 18:27 #127112

by tommylight

Replied by tommylight on topic A question of Scale.....

Not 10 microsteps, G540 has a divider by 10, it has NO microstepping. Had 2 of them, got rid of them. They are very nice and really powerful for such a small package, but i could not live with 9 steps doing nothing.That high Microstepping kills all your Performence but ads allot of Issues to your machine

10 Microsteps as Fixed on the G540 Whow

Please Log in or Create an account to join the conversation.

Time to create page: 0.123 seconds