Z homing touch plate - hardware/software input

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

09 Sep 2019 21:15 #144631

by randypetersen

Z homing touch plate - hardware/software input was created by randypetersen

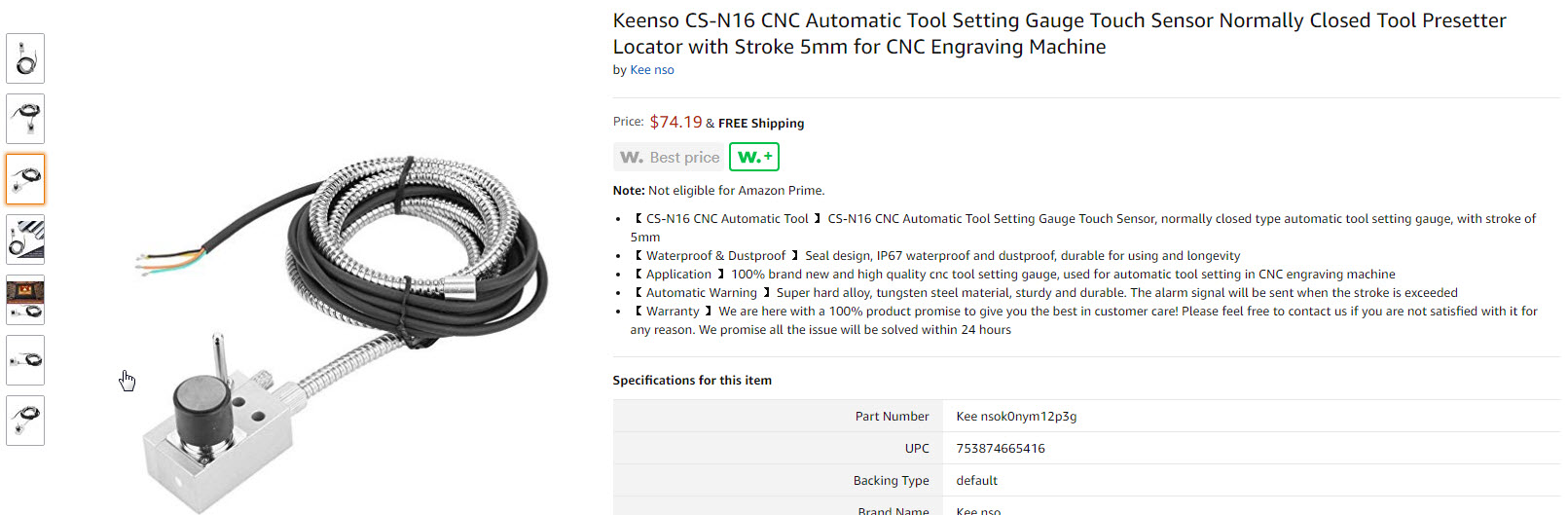

Here is some pics of the Z touch plate that came with my CNC. However, I cannot figure out for the life of me how it would work.

As you can see there are 2 wires going to the plate, both are connected to plate so there is no resistance between those 2 wires. They run to the controller and have been identified.

My understanding is that I would need a wire going to the tool and one to the plate. However I can't find any conductor going from the tool/spindle to the controller. I think the spindle is insulated? Would I have to run another wire to the spindle that would be clamped on tool? or is there any other way around this?

I created one of these pretty simply with my old parallel port / mach3 setup. I did have to clamp on to the tool though. Wasn't sure if that would always be required of if there was a better way?

Then what's the best practice for setting up a Z homing procedure within LinuxCNC?

Thanks for any info!

As you can see there are 2 wires going to the plate, both are connected to plate so there is no resistance between those 2 wires. They run to the controller and have been identified.

My understanding is that I would need a wire going to the tool and one to the plate. However I can't find any conductor going from the tool/spindle to the controller. I think the spindle is insulated? Would I have to run another wire to the spindle that would be clamped on tool? or is there any other way around this?

I created one of these pretty simply with my old parallel port / mach3 setup. I did have to clamp on to the tool though. Wasn't sure if that would always be required of if there was a better way?

Then what's the best practice for setting up a Z homing procedure within LinuxCNC?

Thanks for any info!

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

10 Sep 2019 06:06 #144661

by pl7i92

Replied by pl7i92 on topic Z homing touch plate - hardware/software input

seams like a omic sence

get 5V on the plate and mesure the resistence if a steel tool touch the plate

get 5V on the plate and mesure the resistence if a steel tool touch the plate

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20824

- Thank you received: 7098

10 Sep 2019 06:55 #144672

by tommylight

Replied by tommylight on topic Z homing touch plate - hardware/software input

If using parallel port, just ground the spindle/machine and wire the sensor to on of the inputs on the parallel port.

No wires needed. Parallel port can sense input pins going to ground so that is easy.

If you have a BOB, you might need to add a pull up resistor for it to work.

No wires needed. Parallel port can sense input pins going to ground so that is easy.

If you have a BOB, you might need to add a pull up resistor for it to work.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

10 Sep 2019 07:01 #144674

by pl7i92

Replied by pl7i92 on topic Z homing touch plate - hardware/software input

@ tommy

dont you think it workes like renishow high sense reed relai

the large detector plate lets me think of this

dont you think it workes like renishow high sense reed relai

the large detector plate lets me think of this

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20824

- Thank you received: 7098

10 Sep 2019 07:06 #144676

by tommylight

Replied by tommylight on topic Z homing touch plate - hardware/software input

It's a metal plate so the reed relay will not work inside it. Reed relays react to magnets or magnetic field.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

10 Sep 2019 07:17 #144678

by pl7i92

Replied by pl7i92 on topic Z homing touch plate - hardware/software input

not direct reed relais some kind of that sence

BUT im with you it may only ((black pice)) be a pice of Electric shield to the Mashine

he needs to get a meter on to see what hapens without a mashine connect

meter BLACK to one pin of detector connector

the other to a BIT/tool in Hand and just touch

while meter is in Detect Thrue mode / ""Durchgangsprüfung""

then he is fine and can simply direct BOB connect via ground detect

I DO NOT RECOMED BOB ground on Mashine AS so many using that

BUT im with you it may only ((black pice)) be a pice of Electric shield to the Mashine

he needs to get a meter on to see what hapens without a mashine connect

meter BLACK to one pin of detector connector

the other to a BIT/tool in Hand and just touch

while meter is in Detect Thrue mode / ""Durchgangsprüfung""

then he is fine and can simply direct BOB connect via ground detect

I DO NOT RECOMED BOB ground on Mashine AS so many using that

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

09 Oct 2019 16:23 #147575

by randypetersen

Replied by randypetersen on topic Z homing touch plate - hardware/software input

I still haven't had any luck on this, maybe I need to purchase or build a different Z plate.

Between the bit and the ground there is some resistance but it's a connection. I missed it at first because I was just listening for a continuity beep from my meter, however there is a connection between bit and ground wires.

How could I wired that up?

I am using a Mesa 7i77 & 7i92 boards.

Anyone have any thoughts?

Thanks!

Randy

Between the bit and the ground there is some resistance but it's a connection. I missed it at first because I was just listening for a continuity beep from my meter, however there is a connection between bit and ground wires.

How could I wired that up?

I am using a Mesa 7i77 & 7i92 boards.

Anyone have any thoughts?

Thanks!

Randy

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

11 Oct 2019 13:55 #147702

by randypetersen

Replied by randypetersen on topic Z homing touch plate - hardware/software input

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19677

- Thank you received: 4552

18 Oct 2019 13:08 #148196

by andypugh

Replied by andypugh on topic Z homing touch plate - hardware/software input

You might be able to add an opto-isolator (or even a relay) to the touch-plate circuit to convert the resistance change to an on/off signal for the GPIO.

Please Log in or Create an account to join the conversation.

Time to create page: 0.213 seconds