X Axis Travel Accuracy

- Jason Arnold

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

20 Oct 2019 02:07 #148385

by Jason Arnold

X Axis Travel Accuracy was created by Jason Arnold

Hi Guys,

I've searched the forum for a solution but failed to find something relevant to my problem. So a new topic it is.

I've had an issue for some time and have been able to live with it but curiosity has got the better of me and I want to get to the bottom of the problem.

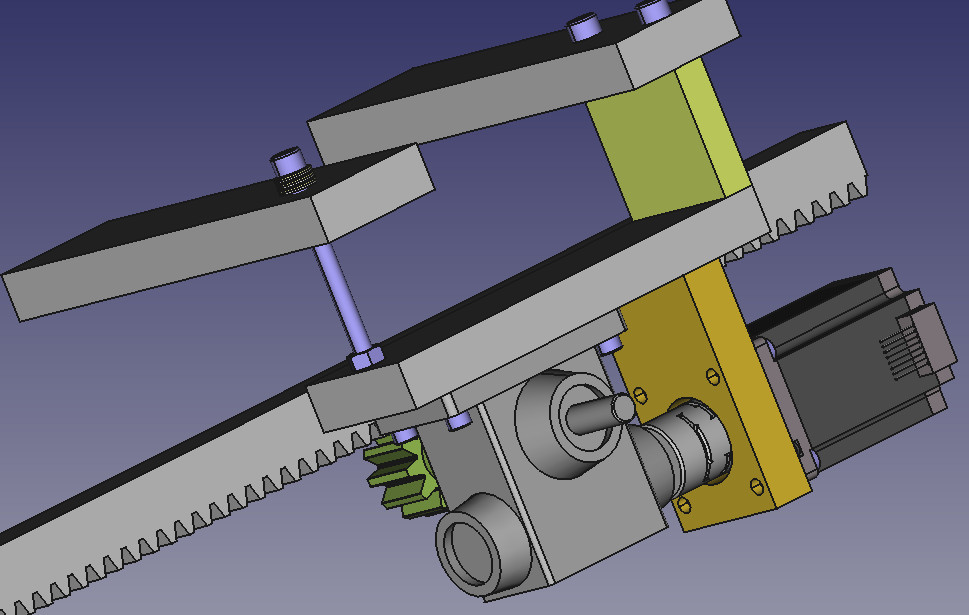

What is the problem: The accuracy of my X axis is in question. I have X setup as the axis moving the spindle left to right and the Y axis is the gantry. See the picture. If I manually command the machine to move X 6" it will always move to within ~1/32" under 6". Move it back to 0 and it comes back exactly to where it started. The movement is very consistent and repeatable! The Y axis which is the gantry will move exactly from 0 to 6". Mmmmm. Scratch ones head...

If I manually command the machine to move X 6" it will always move to within ~1/32" under 6". Move it back to 0 and it comes back exactly to where it started. The movement is very consistent and repeatable! The Y axis which is the gantry will move exactly from 0 to 6". Mmmmm. Scratch ones head...

Some info on the machine:

X & Y axis are rack & pinion drive with Nema 23 steppers. These items were purchased from CNC Routerparts as a kit.

The X axis has one stepper whereas the gantry (Y axis) has two steppers.

The CNC router parts R&P system uses belt reduction with 3:1 ratio. The pinion is a 1" PCD and the rack is 20 teeth/inch.

The driver is a Gecko G540.

What have I done to narrow the problem down?

1. First thing I tried was checking the X axis drive trim on the G540. It was in the sweet spot and no accuracy improvement or change at other trim settings.

2. Swapped one stepper from the Y axis to the X axis. No change in accuracy.

3. Swapped the X cable from the G540 to the Y axis and manually moved the Y axis from 0 to 6". Same result of being about 1/32" short of 6".

4. Checked the X axis for any binding or slop. There is no binding and with R&P no discernible slop.

So from the above checks, I think I have eliminated the G540 and Stepper motors. The X axis repeatably moves as instructed only that it's less than it should be.

Any ideas or suggestions?

Cheers,

Jason.

I've searched the forum for a solution but failed to find something relevant to my problem. So a new topic it is.

I've had an issue for some time and have been able to live with it but curiosity has got the better of me and I want to get to the bottom of the problem.

What is the problem: The accuracy of my X axis is in question. I have X setup as the axis moving the spindle left to right and the Y axis is the gantry. See the picture.

Some info on the machine:

X & Y axis are rack & pinion drive with Nema 23 steppers. These items were purchased from CNC Routerparts as a kit.

The X axis has one stepper whereas the gantry (Y axis) has two steppers.

The CNC router parts R&P system uses belt reduction with 3:1 ratio. The pinion is a 1" PCD and the rack is 20 teeth/inch.

The driver is a Gecko G540.

What have I done to narrow the problem down?

1. First thing I tried was checking the X axis drive trim on the G540. It was in the sweet spot and no accuracy improvement or change at other trim settings.

2. Swapped one stepper from the Y axis to the X axis. No change in accuracy.

3. Swapped the X cable from the G540 to the Y axis and manually moved the Y axis from 0 to 6". Same result of being about 1/32" short of 6".

4. Checked the X axis for any binding or slop. There is no binding and with R&P no discernible slop.

So from the above checks, I think I have eliminated the G540 and Stepper motors. The X axis repeatably moves as instructed only that it's less than it should be.

Any ideas or suggestions?

Cheers,

Jason.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

20 Oct 2019 12:38 #148406

by Mike_Eitel

Replied by Mike_Eitel on topic X Axis Travel Accuracy

You have to adapt your scale value.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

20 Oct 2019 16:32 #148415

by pl7i92

Replied by pl7i92 on topic X Axis Travel Accuracy

Attachments:

Please Log in or Create an account to join the conversation.

- Jason Arnold

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

20 Oct 2019 19:00 #148420

by Jason Arnold

Replied by Jason Arnold on topic X Axis Travel Accuracy

Hi Mike,

Thank you for your reply.

The X axis is setup the same as the Y. Both axis use the same rack and pinion systems with the only difference being that the Y axis has two racks and drives.

Would it be normal to need a different scale on the X axis?

Cheers,

Jason.

Thank you for your reply.

The X axis is setup the same as the Y. Both axis use the same rack and pinion systems with the only difference being that the Y axis has two racks and drives.

Would it be normal to need a different scale on the X axis?

Cheers,

Jason.

Please Log in or Create an account to join the conversation.

- Jason Arnold

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

20 Oct 2019 19:07 #148421

by Jason Arnold

Replied by Jason Arnold on topic X Axis Travel Accuracy

Hi Pl7i92,

Thank you for your reply.

The rack and pinion drive is made by CNC router parts. www.cncrouterparts.com/standard-rack-and...ve-nema-23-p-50.html

Here are the settings they suggest for their system:

MACH Settings for R&P:

The R&P system is based on a pinion with a 1" pitch circle. The total linear distance traveled per revolution of the pinion is thus 3.14159". With the 3:1 reduction, this means that the distance traveled per motor revolution is 3.14159 / 3, or 1.0472". If you have a stepper with 200 steps per revolution, this means you have 200 / 1.0472" = 190.9861 steps per inch, or 0.005236" per step. With 10x microstepping, you would have 1909.861 steps per inch, or 0.0005236" per step. For the optional 3/8" pulley, this number changes to 1736.237, as the motor pulley is slightly larger.

The G540 is set to 10x microstepping.

The pinion is held into the rack with a spring which has a turnbuckle on it so tension can be adjusted. I’ve tried different tensions with no change in accuracy.

Cheers,

Jason.

Thank you for your reply.

The rack and pinion drive is made by CNC router parts. www.cncrouterparts.com/standard-rack-and...ve-nema-23-p-50.html

Here are the settings they suggest for their system:

MACH Settings for R&P:

The R&P system is based on a pinion with a 1" pitch circle. The total linear distance traveled per revolution of the pinion is thus 3.14159". With the 3:1 reduction, this means that the distance traveled per motor revolution is 3.14159 / 3, or 1.0472". If you have a stepper with 200 steps per revolution, this means you have 200 / 1.0472" = 190.9861 steps per inch, or 0.005236" per step. With 10x microstepping, you would have 1909.861 steps per inch, or 0.0005236" per step. For the optional 3/8" pulley, this number changes to 1736.237, as the motor pulley is slightly larger.

The G540 is set to 10x microstepping.

The pinion is held into the rack with a spring which has a turnbuckle on it so tension can be adjusted. I’ve tried different tensions with no change in accuracy.

Cheers,

Jason.

Please Log in or Create an account to join the conversation.

- Jason Arnold

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

20 Oct 2019 20:14 #148427

by Jason Arnold

Replied by Jason Arnold on topic X Axis Travel Accuracy

Mike,

When you say adapt your scale do you mean adjust the "lead screw" pitch parameter in stepconfig wizard?

Cheers,

Jason.

When you say adapt your scale do you mean adjust the "lead screw" pitch parameter in stepconfig wizard?

Cheers,

Jason.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

20 Oct 2019 21:01 #148433

by Mike_Eitel

Replied by Mike_Eitel on topic X Axis Travel Accuracy

Pl7i92 has rosen a good point. Is the x axis independent from travel distance? I gues that happens.

If yes, you have to look for backlash. For this you should read

linuxcnc.org/docs/2.7/html/config/ini-config.html chapter 2.11.......

BACKLASH = 0.0000 - Backlash is in machine units. Backlash compensation can be used to make..........

If it is distance related then you have to do scaling. But sorry, I do only direct editing in the hal file.

SCALE = 1909.8 is your candidate to modify in [AXIS-0]

Good luck

Mike

If yes, you have to look for backlash. For this you should read

linuxcnc.org/docs/2.7/html/config/ini-config.html chapter 2.11.......

BACKLASH = 0.0000 - Backlash is in machine units. Backlash compensation can be used to make..........

If it is distance related then you have to do scaling. But sorry, I do only direct editing in the hal file.

SCALE = 1909.8 is your candidate to modify in [AXIS-0]

Good luck

Mike

Please Log in or Create an account to join the conversation.

- Jason Arnold

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

20 Oct 2019 21:32 #148434

by Jason Arnold

Replied by Jason Arnold on topic X Axis Travel Accuracy

Hi Mike,

The problem is distance related. If I manually tell the X axis to move 6" it only moves 5" and 31/32". It does that every time too.

I can't feel or see any backlash in this R&P system. With the machine powered up and a dial indicator on the axis the machine holds very solid when I attempt to move the X axis. I need to check the scale of the dial but I'm sure it only moves the needle +/- 0.001"

I'll have a play around with the scale but it does my head in a little why the Y axis is bang on in distance travelled with identical settings and R&P system.

Cheers,

Jason.

The problem is distance related. If I manually tell the X axis to move 6" it only moves 5" and 31/32". It does that every time too.

I can't feel or see any backlash in this R&P system. With the machine powered up and a dial indicator on the axis the machine holds very solid when I attempt to move the X axis. I need to check the scale of the dial but I'm sure it only moves the needle +/- 0.001"

I'll have a play around with the scale but it does my head in a little why the Y axis is bang on in distance travelled with identical settings and R&P system.

Cheers,

Jason.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

21 Oct 2019 02:32 #148438

by Leon82

Replied by Leon82 on topic X Axis Travel Accuracy

Could you have accidentally been shipped a metric unit?

5mm and 3/16 are close enough by eye but only get noticed with an indicator untill you get into long distances

5mm and 3/16 are close enough by eye but only get noticed with an indicator untill you get into long distances

Please Log in or Create an account to join the conversation.

- Jason Arnold

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

21 Oct 2019 02:51 #148439

by Jason Arnold

Replied by Jason Arnold on topic X Axis Travel Accuracy

They only have two options and both are imperial. 1/4" (20 Teeth pinion) and 3/8" (22 teeth pinion).

When I swapped the steppers it was just the motor and small pulley on the motor. Not the big pulley with pinion.

Cheers,

Jason.

When I swapped the steppers it was just the motor and small pulley on the motor. Not the big pulley with pinion.

Cheers,

Jason.

Please Log in or Create an account to join the conversation.

Time to create page: 0.087 seconds