- Configuring LinuxCNC

- Basic Configuration

- Full Revolution issues - Rotary Axis - Barrel Organ Machine

Full Revolution issues - Rotary Axis - Barrel Organ Machine

- pijki

- Offline

- New Member

-

- Posts: 6

- Thank you received: 0

I'm working on a special machine to cut cardboard for barrel organ (my parents are making these french musical instruments). It's a 3 axis machine and im using the MX3660 driver with Linux cnc 2.7. Here the beta version of the machine on my website : antoninodin.com/CARDBOARD-MACHINE ) .

I have an issue with the rotary axis A, I dont manage to do a full revolution in both direction : when I do a G91 G0 A360 it's OK but when I do a G91 G0 A-360 there is an offset ( I have marked my physicial axis to see it). I have tried to change the settings all the day but I dont underrstand why I dont have a full revolution in both directions...

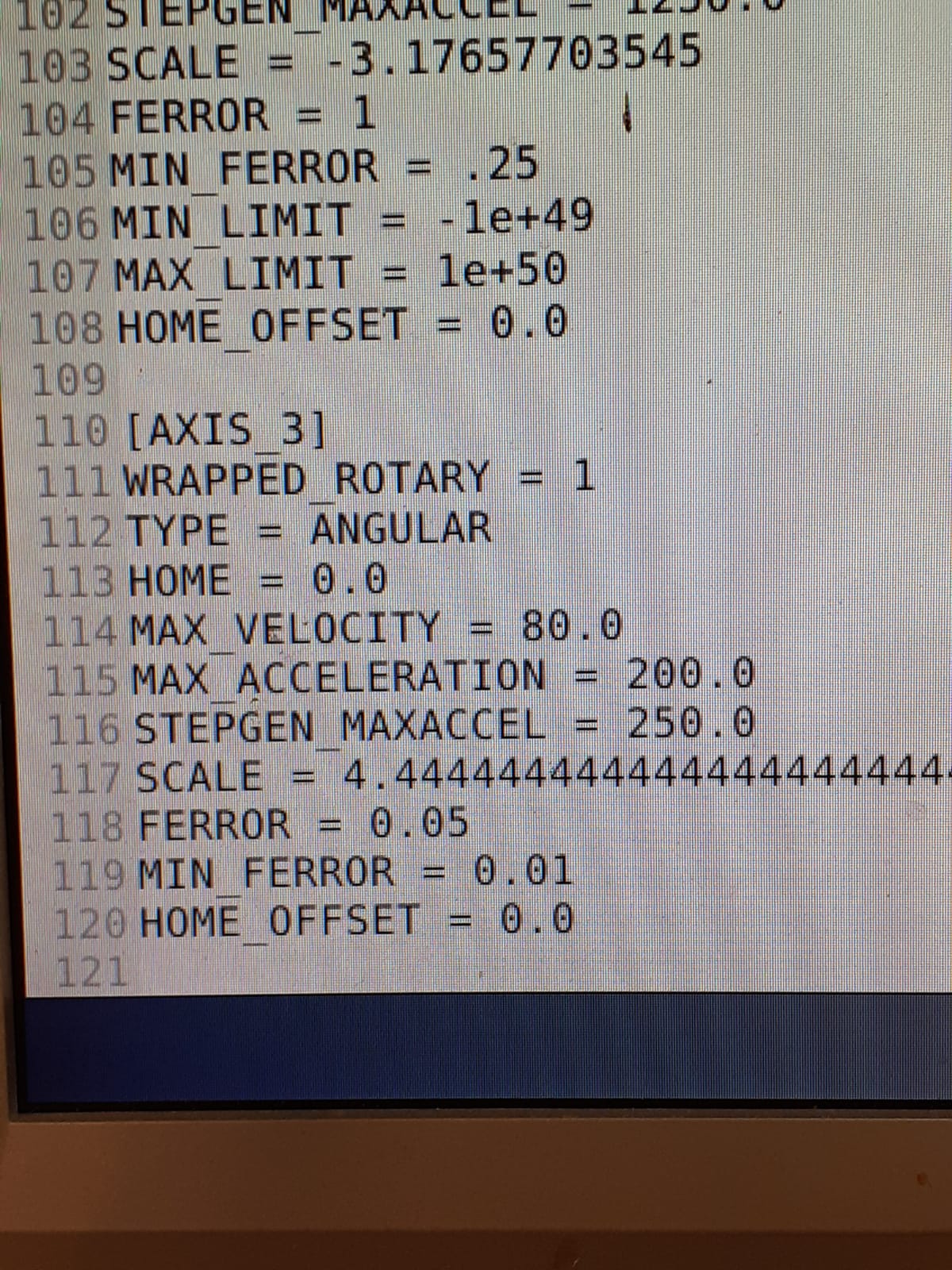

Here the settings of the A axis in the Ini files :

Thanks a lot for your help.

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

It's usually better to attach your HAL and INI files to your post.

Is the offset always the same and is there also the same effect when you use G90?

Please Log in or Create an account to join the conversation.

- pijki

- Offline

- New Member

-

- Posts: 6

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

2. I am unfamiliar with the "Wrapped rotary" function but the manual states:

So it would seem that 360 is then outside the allowed range. Is there a particular reason to use "WRAPPED_ROTARY=1"? I also use a rotary axis but have never used it. I didn't even know this feature existed. Have you tried without it?WRAPPED_ROTARY = 1 - When this is set to 1 for an ANGULAR axis the axis will move 0-359.999 degrees. Positive Numbers will move the axis in a positive direction and negative numbers will move the axis in the negative direction.

[edit]

Ok, I just read up on the wrapped_rotary and it prevents the wind up of the angular value so that might make sense. Nevertheless it might be worth to try things out without it.

Please Log in or Create an account to join the conversation.

- pijki

- Offline

- New Member

-

- Posts: 6

- Thank you received: 0

I have tried without the Wrapped_Rotary and it's not changing anything.

What is weird is that I can send G91 G0 A360 many times and I will never have any offset, but when It's a G91 G0 A-360, it's seems that the motor is doing less steps that needed... By testing, i figured it out that a G91 G0 A-364.4 is actually doing a full revolution, but i dont understand why ?

I was expecting that a A360 and a A-360 will do a full revolution and having both at the exact same position...

thanks for your help!

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

Well that is certainly what we would expect.I was expecting that a A360 and a A-360 will do a full revolution and having both at the exact same position...

So maybe try the following:

1. Jog the axis in the negative direction (-360°) to the mark

2. command G91 G0 A360

3. report if the turn was a full revolution or if there is an offset

[edit]

Since you made two revolutions in both directions in the video I'm wondering what happens if you do only one revolution. Is the offset only half and If you do four revolutions is the offset then doubled?

Please Log in or Create an account to join the conversation.

- pijki

- Offline

- New Member

-

- Posts: 6

- Thank you received: 0

So to sum up, once the origin is defined, If the first jog is negative (-360°), the positive jog (+360) will be offset. In the contrary, if the first jog is positive, it's the negative jog that will be offset.

The offset is always the same whatever is 1 or 4 revolutions.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

- Posts: 544

- Thank you received: 105

WHAT is the MICROSTEPPING of the MX3660 set

and what is the Drive system Timingbelt 5:1 ?

Please Log in or Create an account to join the conversation.

- pijki

- Offline

- New Member

-

- Posts: 6

- Thank you received: 0

I'm not sure about what you mean about "Drive system Timigbelt 5:1", as the picture posted below, this axis is a direct drive, and there is no timigbelt.what is the Drive system Timingbelt 5:1 ?

I have tried to change the microstepping and the scale, but i had still some offset...

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

If it also occurs with just the naked motor then it seems that you are losing steps while reversing the motor for which I have no possible explanation at the moment.

Have you tried to assign the rotary axis to one of the other motors in HAL and tested it that way?

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Basic Configuration

- Full Revolution issues - Rotary Axis - Barrel Organ Machine