Trapezoidal home limit actuators (or not)

- rootboy

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 76

- Thank you received: 25

17 Aug 2020 15:55 #178483

by rootboy

Trapezoidal home limit actuators (or not) was created by rootboy

Hi guys,

I'm helping a friend upgrade his Takamatsu lathe to LinuxCNC and his lathe has three limit switches per axis.

In order, they are:

1) Max overtravel.

2) Min overtravel.

3) Home.

We aren't totally in agreement on the Home limit actuator. It's shaped as a trapezoid, and it makes, and then comes off of, the actuator given its shape. Apparently its profile is designed intentionally to do this.

Thurston thinks it's used for slowdown only, which would allow the machine to speed back up just in time to hit the overtravel.

I'm an old Controls Engineer, and we would never use a slowdown actuator block that didn't maintain the slowdown limit until it got to the overtravel (well, not more than once, hopefully).

Being an island of its own out there adds to the confusion, is the homing sequence going to work in the case of the machine being between the home limit actuator and the overtravel actuator? Will it still work with the machine past the home limit actuator. In the first scenario the machine will hit the OT actuator first, and then back off until it hits the home limit actuator (I presume). In the second scenario the machine will hit the other slope of the home actuator first and then the OT actuator. Will that still work?

To add to the confusion, the Home limit switch (an Omron "Microswitch" design) gave up the ghost and is now on my desk waiting on its replacement. So I've been playing with the "Shared limit" homing sequence since I am currently without a working home limit switch on the X axis. And yeah, we will be replacing all six of them...

We are both leaning towards leaving it this way since the position of the home actuator eats up a fair amount of usable stroke, and it really isn't necessary since the machine is set up to drop out the positive motion when it hits the positive OT limit, and drop out the negative motion when it hits the negative limit. This has been checked out and it works, so I'm not too worried about causing physical damage to the ball screw.

I've taken a stab at doing just that, but I'm getting "Hit limit in home state 7" errors. I've tried moving the home position off of the OT by .5" in each direction (+0.5 and -0.5), but no luck. And I can't get the axis to jog so I am not 100% sure that I am even going in the correct direction.

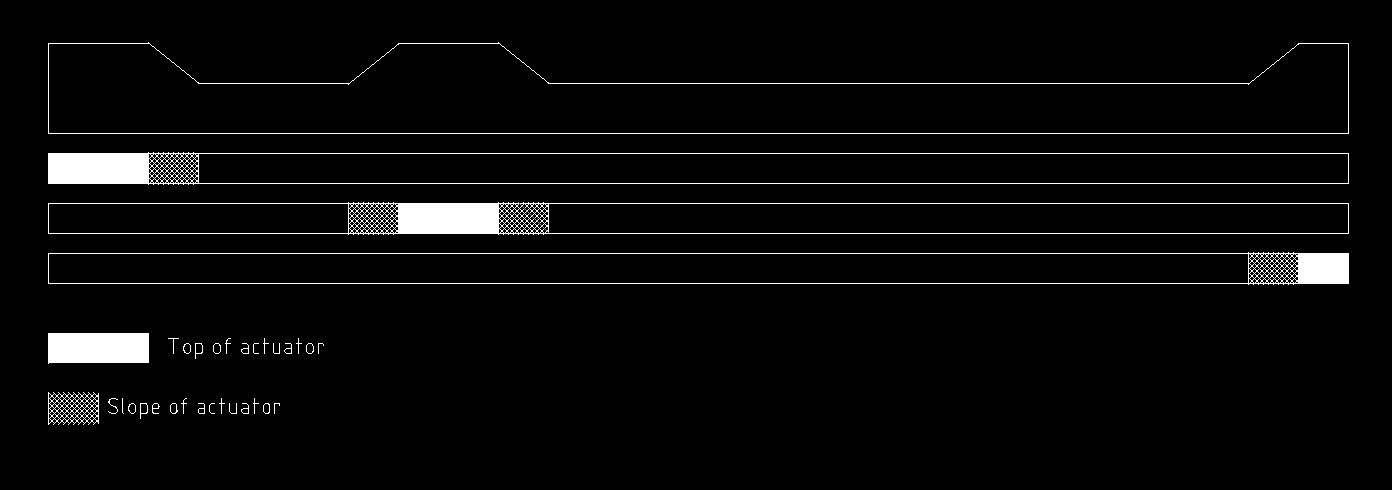

I drew up a picture of what we are working with and included it.

Thanks!

John

I'm helping a friend upgrade his Takamatsu lathe to LinuxCNC and his lathe has three limit switches per axis.

In order, they are:

1) Max overtravel.

2) Min overtravel.

3) Home.

We aren't totally in agreement on the Home limit actuator. It's shaped as a trapezoid, and it makes, and then comes off of, the actuator given its shape. Apparently its profile is designed intentionally to do this.

Thurston thinks it's used for slowdown only, which would allow the machine to speed back up just in time to hit the overtravel.

I'm an old Controls Engineer, and we would never use a slowdown actuator block that didn't maintain the slowdown limit until it got to the overtravel (well, not more than once, hopefully).

Being an island of its own out there adds to the confusion, is the homing sequence going to work in the case of the machine being between the home limit actuator and the overtravel actuator? Will it still work with the machine past the home limit actuator. In the first scenario the machine will hit the OT actuator first, and then back off until it hits the home limit actuator (I presume). In the second scenario the machine will hit the other slope of the home actuator first and then the OT actuator. Will that still work?

To add to the confusion, the Home limit switch (an Omron "Microswitch" design) gave up the ghost and is now on my desk waiting on its replacement. So I've been playing with the "Shared limit" homing sequence since I am currently without a working home limit switch on the X axis. And yeah, we will be replacing all six of them...

We are both leaning towards leaving it this way since the position of the home actuator eats up a fair amount of usable stroke, and it really isn't necessary since the machine is set up to drop out the positive motion when it hits the positive OT limit, and drop out the negative motion when it hits the negative limit. This has been checked out and it works, so I'm not too worried about causing physical damage to the ball screw.

I've taken a stab at doing just that, but I'm getting "Hit limit in home state 7" errors. I've tried moving the home position off of the OT by .5" in each direction (+0.5 and -0.5), but no luck. And I can't get the axis to jog so I am not 100% sure that I am even going in the correct direction.

I drew up a picture of what we are working with and included it.

Thanks!

John

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20830

- Thank you received: 7100

17 Aug 2020 17:40 #178494

by tommylight

Replied by tommylight on topic Trapezoidal home limit actuators (or not)

From your post, you mention machine has 3 limit switches, then it has only one and three bumps ?

Which is it?

Form the drawing, it definitely has only one.

In that case i would grind the second bump and used the shared limits/home.

Which is it?

Form the drawing, it definitely has only one.

In that case i would grind the second bump and used the shared limits/home.

Please Log in or Create an account to join the conversation.

- rootboy

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 76

- Thank you received: 25

17 Aug 2020 23:25 - 17 Aug 2020 23:26 #178551

by rootboy

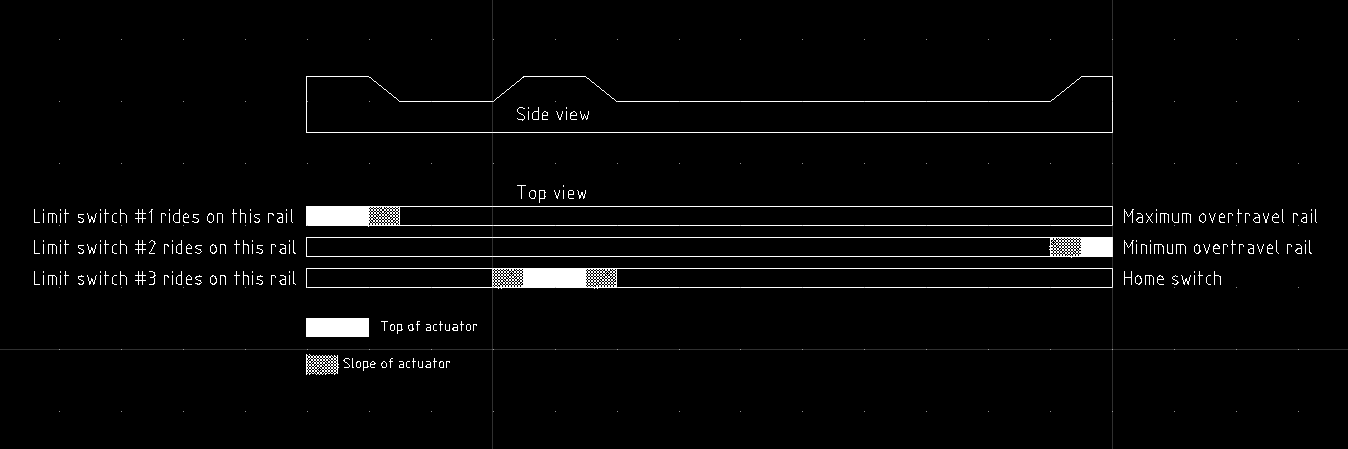

Well, I meant to display three separate rails, the top view showing what the three would look like while looking at it from the side (just to show where the raised areas are for the actuators on all three rails).

I did get the order of the three top views of the rails incorrect, so I re-did the drawing and straightened that out. And I added documentation for switches 1 - 3 to make that clearer.

Thurston and I have come to an agreement that having a home position that would get defined by which side of the actuator block it's on is less than useful. To put it mildly.

So Thurston's going to modify the home blocks so that once it makes it won't drop off of it again as the X and Z axis travels in the positive direction. No more trapezoids.

Once I get the replacement limit switches I'll be able to try it out.

Thanks!

John

Replied by rootboy on topic Trapezoidal home limit actuators (or not)

From your post, you mention machine has 3 limit switches, then it has only one and three bumps ?

Which is it?

Form the drawing, it definitely has only one.

In that case i would grind the second bump and used the shared limits/home.

Well, I meant to display three separate rails, the top view showing what the three would look like while looking at it from the side (just to show where the raised areas are for the actuators on all three rails).

I did get the order of the three top views of the rails incorrect, so I re-did the drawing and straightened that out. And I added documentation for switches 1 - 3 to make that clearer.

Thurston and I have come to an agreement that having a home position that would get defined by which side of the actuator block it's on is less than useful. To put it mildly.

So Thurston's going to modify the home blocks so that once it makes it won't drop off of it again as the X and Z axis travels in the positive direction. No more trapezoids.

Once I get the replacement limit switches I'll be able to try it out.

Thanks!

John

Attachments:

Last edit: 17 Aug 2020 23:26 by rootboy. Reason: Make things clearer.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11452

- Thank you received: 3839

18 Aug 2020 09:45 #178582

by rodw

Replied by rodw on topic Trapezoidal home limit actuators (or not)

Sounds like you worked it out. Once the home switch is triggered, it must stay triggered all the way to the limit switch. That way Linuxcnc will know which way to travel when homing commences.

When a home switch is hit, the axis slows at a very safe rate to avoid any loss of steps/position. With a fairly large machine, I found that frustrating as you needed to allow plenty of room from the home switch to the limit otherwise the homing velocity must be reduced to reduce this travel. This is also a good argument against shared limit switches. So I love to hear there are others out there who don't take shortcuts with home and limit switches.

When a home switch is hit, the axis slows at a very safe rate to avoid any loss of steps/position. With a fairly large machine, I found that frustrating as you needed to allow plenty of room from the home switch to the limit otherwise the homing velocity must be reduced to reduce this travel. This is also a good argument against shared limit switches. So I love to hear there are others out there who don't take shortcuts with home and limit switches.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

18 Aug 2020 13:11 #178598

by Clive S

Rod. I don't understand this and certainly don't take shortcuts, I have built several routers with dual axis and never had trouble with shared home and limits.

If it does over shoot slightly the axis will back off the switch and latch them move away from the switch to the home position so as to not have any false triggers .

I I was using servos that had to potential to run away with a fault condition I then would of course have limits at each end of travel wired in series. Limits are an emergency situation and are never reached in normal operation as the soft limit stop you from jogging into them or the home switch.

Replied by Clive S on topic Trapezoidal home limit actuators (or not)

This is also a good argument against shared limit switches. So I love to hear there are others out there who don't take shortcuts with home and limit switches.

Rod. I don't understand this and certainly don't take shortcuts, I have built several routers with dual axis and never had trouble with shared home and limits.

If it does over shoot slightly the axis will back off the switch and latch them move away from the switch to the home position so as to not have any false triggers .

I I was using servos that had to potential to run away with a fault condition I then would of course have limits at each end of travel wired in series. Limits are an emergency situation and are never reached in normal operation as the soft limit stop you from jogging into them or the home switch.

Please Log in or Create an account to join the conversation.

- rootboy

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 76

- Thank you received: 25

18 Aug 2020 14:41 #178604

by rootboy

Having an actuator that could make on either side didn't make any sense whatsoever. Thurston thought that it was used as a slowdown limit (we have no way of knowing since there is no documentation whatsoever on this lathe).

But I've seen that method used before on larger lifts (around 7,000 pounds of load), where the slowdown speed is latched into memory. Invariably something happens to unlatch it, and the lift barrels into the hard stops. Normally it wouldn't damage anything, but you could hear the event from out in the parking lot.

From a controls standpoint it made no sense to use this kind of actuator. I imagine a homing sequence could be set up to differentiate which side of the home actuator the machine was hitting, but why would anyone go through all of that trouble?

I've had to do this in PLCs, so I know that it can be done. But it costs more to machine the unused side of the actuator than it would to extend the actuator an additional inch. Silly.

And it does look like it is intended to be the home switch, it has slots at the base of the actuator for adjustment, and it's been moved to allow for maximum travel.

As for using shared limits, if you still have adequate travel to compensate for the overshoot after it actuates, then it should be fine.

After all, it's how my 3D printers home themselves. But I don't think that the Taka was intended to be homed this way so I'd rather not try it.

I do have it setup as intended from the factory where the drives will drop out when it hits the OT in that direction (the opposite direction will still work). This is hardwired into the drive and can't be programmed around.

But these limit switches are old (and soon to be completely replaced for new ones), and not what I would have used in the first place for what could end up wrecking a ball screw.

And ball screws are simply out of my price range. ;>

Thanks for your help!

John

Replied by rootboy on topic Trapezoidal home limit actuators (or not)

Sounds like you worked it out. Once the home switch is triggered, it must stay triggered all the way to the limit switch. That way Linuxcnc will know which way to travel when homing commences.

When a home switch is hit, the axis slows at a very safe rate to avoid any loss of steps/position. With a fairly large machine, I found that frustrating as you needed to allow plenty of room from the home switch to the limit otherwise the homing velocity must be reduced to reduce this travel. This is also a good argument against shared limit switches. So I love to hear there are others out there who don't take shortcuts with home and limit switches.

Having an actuator that could make on either side didn't make any sense whatsoever. Thurston thought that it was used as a slowdown limit (we have no way of knowing since there is no documentation whatsoever on this lathe).

But I've seen that method used before on larger lifts (around 7,000 pounds of load), where the slowdown speed is latched into memory. Invariably something happens to unlatch it, and the lift barrels into the hard stops. Normally it wouldn't damage anything, but you could hear the event from out in the parking lot.

From a controls standpoint it made no sense to use this kind of actuator. I imagine a homing sequence could be set up to differentiate which side of the home actuator the machine was hitting, but why would anyone go through all of that trouble?

I've had to do this in PLCs, so I know that it can be done. But it costs more to machine the unused side of the actuator than it would to extend the actuator an additional inch. Silly.

And it does look like it is intended to be the home switch, it has slots at the base of the actuator for adjustment, and it's been moved to allow for maximum travel.

As for using shared limits, if you still have adequate travel to compensate for the overshoot after it actuates, then it should be fine.

After all, it's how my 3D printers home themselves. But I don't think that the Taka was intended to be homed this way so I'd rather not try it.

I do have it setup as intended from the factory where the drives will drop out when it hits the OT in that direction (the opposite direction will still work). This is hardwired into the drive and can't be programmed around.

But these limit switches are old (and soon to be completely replaced for new ones), and not what I would have used in the first place for what could end up wrecking a ball screw.

And ball screws are simply out of my price range. ;>

Thanks for your help!

John

Please Log in or Create an account to join the conversation.

Time to create page: 0.144 seconds