Setting up Remora for laser cutting

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

if you are having issues with the remora pwm gen i would say to skip it for now.

Just have remora give you a normal output pin and then have linux cnc make the PWM signal.

I asked the creator about the ability to set freq of the pwm in his github but im not sure if its going to be worked on yet i think the tmc driver are still being done.

I've looked at the remora sources and found the modules/pwm and that's where I realized it was infect doing PDM instead of PWM.

Then that reminded me that there was a Servo setting for pins(RCSERVO type) so I tried that just to see on an O'scope what the default frequency might be. Standard is 50Hz so too low for me but maybe it could be moded to take a parameter to specify a particular frequency. I've not heard anything yet from Scott Alford yet on his thoughts on this. indeed he is working on the tmc5160 drivers and DC motor control.

some reading in regards to pwm scroll down and you will find it

linuxcnc.org/docs/2.8/html/hal/rtcomps.html

then take one of the files i uploaded the used linux cnc for the pwm gen and change

setp pwmgen.0.pwm-freq 0 to setp pwmgen.0.pwm-freq 400

This will turn on and off the normal output pin on your 3d printer main board as normal pwm.

I will try implementing Hal generated PWM on another pin and see how that goes. It should get this LinuxCNC laser cutter functionality operational. Looking at my config.txt file I don't see a digital pin defined as Output, but I found you showed a section of your config.txt specifying a digital pin as Output. I will try that. Thanks for your help and guidance.

Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

The firmware config.txt pin definition now looks like this:

{

“Thread”: “Servo”,

“Type”: “PWM”,

“Comment”: “Bed heater PWM”,

“Hardware PWM”: “True”,

“Variable Freq”: “True”,

“Period us”: 200,

“SP”: 0,

“Period SP”: 1,

“PWM Pin”: “2.5”

},

Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

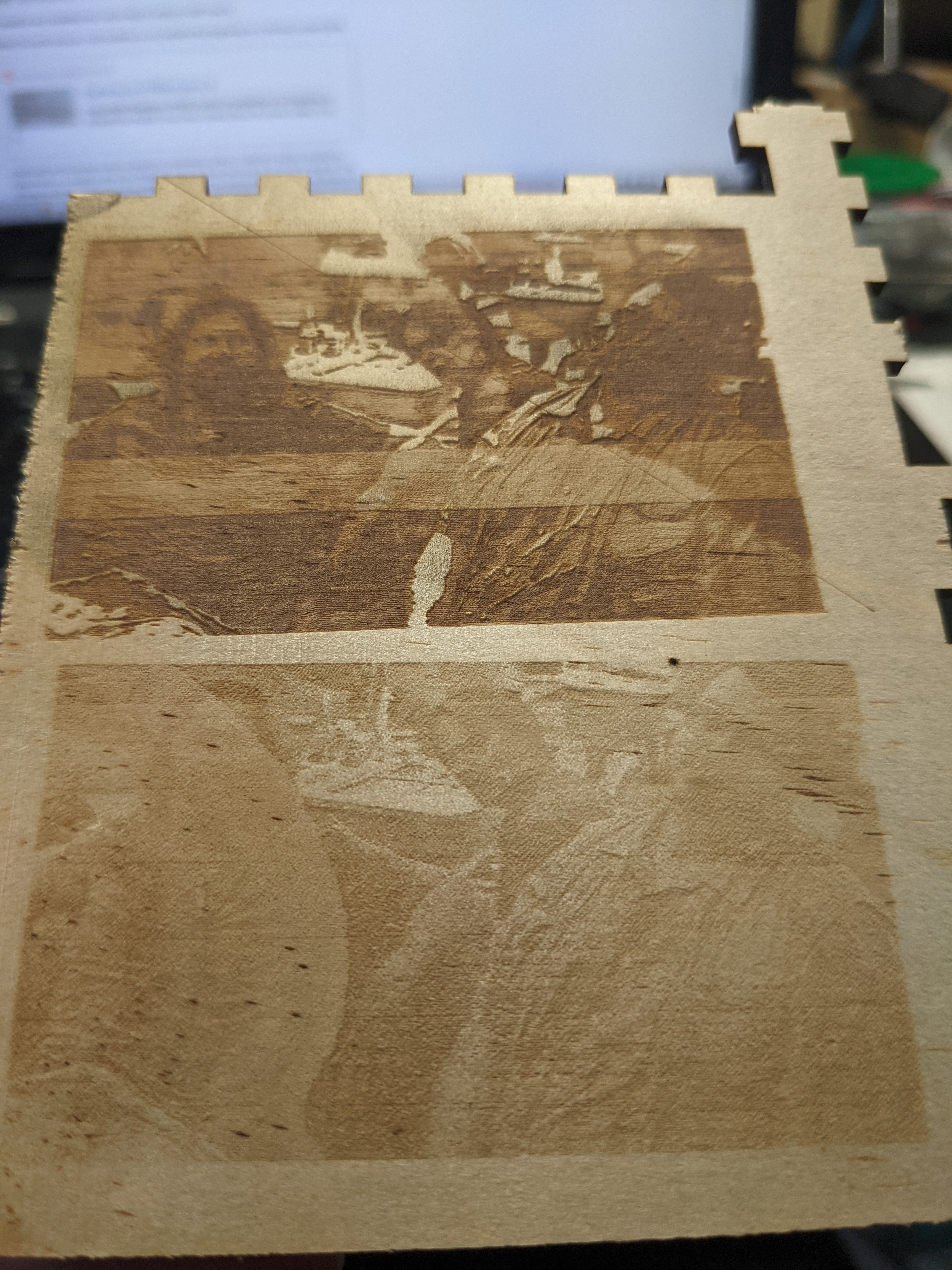

I was really hopeful that LinuxCNC could handle raster laser engraving too(besides just vector cutting) but I've not been able to get it to work at any reasonable speed. There's just too much in the TP pulling down motion when spindle speed is changed. Since I was getting very little from this forum other than to use M67/M68, which didn't work either for the same reason it seems, I started more googling and found out this issue has been beat to death for at least 10 years.

Some people have gone to great lenghts to use LinuxCNC for raster engraving by things like creating custom software to generate a raster file which just moves the tool along X from one side to the other and incrementing Y THEN they create a realtime process outside of LinuxCNC which streams laser power levels to the HAL.

It's too bad because while not everyone is going to try Remora on the K40 laser cutter with a Cohesion, Smoothie or other upgrade boards, there are lots of CNC users putting lasers on their CNC machines at over $1000 a pop and they are add-on kludges. Kludging it with LinuxCNC seems also the only way to make it work.

Now unless Scott comes up with an interesting way to handle the laser power levels with each commanded motion, ie Remora handles what LinuxCNC can't, then this is a dead end and the hopes of rPi/LinuxCNC/Remora on 3D printers and laser cutters and CNC is shot.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21169

- Thank you received: 7232

I am sure i did make it work perfectly smooth at 3m/m since that is the maximum usable for me, usually i use 2m/m, but i need that again i just do not have time to fiddle with it.

Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

It's a shame because it operates the 3D printer nicely and we know it can do any CNC machine.... I thought the laser cutter was a slam dunk easy setup and tough to find people had been messing with this for over 10 years. Would have been really something to show the rPi/LinuxCNC/Remora setup handling the 3 top digital tools of every maker space.

Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

I will try wiring those up in the hal and see what happens.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19773

- Thank you received: 4601

Please Log in or Create an account to join the conversation.

- Aaroncnc

- Offline

- Elite Member

-

- Posts: 204

- Thank you received: 45

the Remora developer has added both fixed frequency PWM and adjustable freq/period hardware PWM and it's now in the main code branch!

The firmware config.txt pin definition now looks like this:

{

“Thread”: “Servo”,

“Type”: “PWM”,

“Comment”: “Bed heater PWM”,

“Hardware PWM”: “True”,

“Variable Freq”: “True”,

“Period us”: 200,

“SP”: 0,

“Period SP”: 1,

“PWM Pin”: “2.5”

},

okay i found an error with the way the forums is handling our configs and why if you copy paste them they fail

doogie take a look at the

“SP[i]”: 0,the forum is removing the square bracket i square bracket

to verify what i am saying hit edit and or quote on my or your config post and notice it shows correctly in the editor but not in the actual post.

{

"Thread": "Servo",

"Type": "PWM",

"Comment": "pwmspindle",

"SP[i]": 3,

"PWM Pin": "2.0",

"Hardware PWM": "True",

"Variable Freq": "True",

"Period SP[i]": 1,

"Period us": 200

},Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

Please Log in or Create an account to join the conversation.

- Doogie

- Offline

- Premium Member

-

- Posts: 108

- Thank you received: 18

Please Log in or Create an account to join the conversation.