Wiring THC A-D 300 to plasma cnc interface.

- ML

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 0

04 Nov 2021 22:29 #225283

by ML

Wiring THC A-D 300 to plasma cnc interface. was created by ML

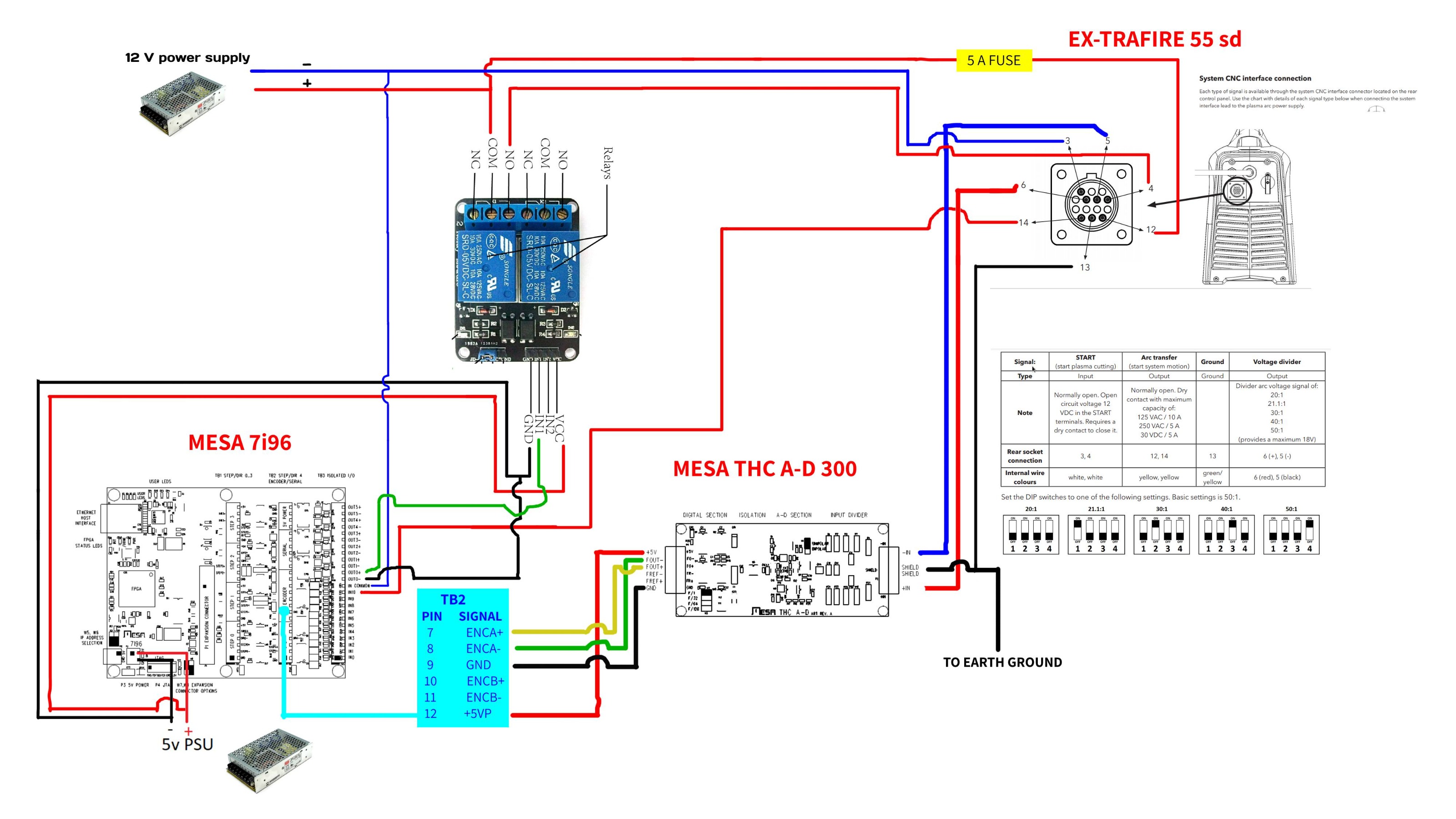

Hello ) Finally I gonna connect my thcad 300 to my plasma cutter (EX-TRAFIRE 55 sd) and MESA 7i96. Next step is installing PlasmaC and burn.

I've found that my plasma cutter is pretty close to HYPERTHERM (I mean CNC interface connector). Moreover I found LOWRIDER2 scheme in Internet how connect THCAD. I draw my variant of wiring scheme and will be thankful if you, guys, have a look at my scheme and check that.

I've found that my plasma cutter is pretty close to HYPERTHERM (I mean CNC interface connector). Moreover I found LOWRIDER2 scheme in Internet how connect THCAD. I draw my variant of wiring scheme and will be thankful if you, guys, have a look at my scheme and check that.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21069

- Thank you received: 7189

04 Nov 2021 23:53 #225303

by tommylight

Replied by tommylight on topic Wiring THC A-D 300 to plasma cnc interface.

THCAD300 is the wrong choice for that plasma source as it has a divider built in giving 18V as the maximum voltage, so with a 300V input will most probably be useless.

It can still be used, but it will require opening the plasma source and wiring stuff inside, also there is only one way of wiring it safely that way.

Beware that if you plan to open the plasma, the THCAD300 manual explicitly mentions not to use it with HF start plasma. Having said that, i have at least 4 in use every day wired that way.

It can still be used, but it will require opening the plasma source and wiring stuff inside, also there is only one way of wiring it safely that way.

Beware that if you plan to open the plasma, the THCAD300 manual explicitly mentions not to use it with HF start plasma. Having said that, i have at least 4 in use every day wired that way.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11565

- Thank you received: 3882

05 Nov 2021 00:00 #225307

by rodw

Replied by rodw on topic Wiring THC A-D 300 to plasma cnc interface.

Tommy is right. Unfortunately, the THCAD-300 is designed for raw arc voltage. Maybe your cutter has another output for raw arc voltage.

But if it does, you may still be in trouble if it includes resistors in the circuit as they will confuse the THCAD300 and alter its scaling. Check the resistance with a multimeter.

But if it does, you may still be in trouble if it includes resistors in the circuit as they will confuse the THCAD300 and alter its scaling. Check the resistance with a multimeter.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21069

- Thank you received: 7189

05 Nov 2021 00:10 #225311

by tommylight

Replied by tommylight on topic Wiring THC A-D 300 to plasma cnc interface.

One more option, a better one, is to change the input resistors on the THCAD300 to make it a THCAD10, a soldering iron and some resistors are required.

Please Log in or Create an account to join the conversation.

- ML

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 0

05 Nov 2021 14:05 #225397

by ML

Replied by ML on topic Wiring THC A-D 300 to plasma cnc interface.

Thanks for your messages! My plasma cutter is under guarantee. I have possibility to change thcad from 300 to 10. I will order new one THCAD -10 today.

What would you say about other wiring: relay, mesa 7i96 and so on?

What would you say about other wiring: relay, mesa 7i96 and so on?

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11565

- Thank you received: 3882

05 Nov 2021 21:14 #225428

by rodw

The purpose of using an industrial board like the 7i96 is to use a higher voltage (eg 24v) which means its much less susceptible to electrical noise and this is important for plasma.

The 7i96 has 2 amp relays built in so using them will reduce failure points and result in a higher MTBF. The lowrider diagram is far from best practice. Just because it looks pretty, people think its the gold standard and its not. Use at least 48v (60-70v is better) on your motors.

Replied by rodw on topic Wiring THC A-D 300 to plasma cnc interface.

I would get rid of the relay board and just use the 7i96 built in relay and replace the 12 v supply with 24v.Thanks for your messages! My plasma cutter is under guarantee. I have possibility to change thcad from 300 to 10. I will order new one THCAD -10 today.

What would you say about other wiring: relay, mesa 7i96 and so on?

The purpose of using an industrial board like the 7i96 is to use a higher voltage (eg 24v) which means its much less susceptible to electrical noise and this is important for plasma.

The 7i96 has 2 amp relays built in so using them will reduce failure points and result in a higher MTBF. The lowrider diagram is far from best practice. Just because it looks pretty, people think its the gold standard and its not. Use at least 48v (60-70v is better) on your motors.

Please Log in or Create an account to join the conversation.

- ML

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 0

05 Nov 2021 22:24 #225442

by ML

Replied by ML on topic Wiring THC A-D 300 to plasma cnc interface.

Thank you for your advice, Rod! I am using motor 86EBP111ALC-TKA and I already bought 36 VDC Power Supply. I have no space in electricity box to use additional power supply for 24 Volts that could be used for Plasma CNC Interface. Moreover it needs 12 VDC (3 and 4 pins on Plasma CNC interface) and dry contact (as I understand Dry contact means wiring NOT trough FPGA card). That is why I gonna use relay.

My plasma has as I understand pnevmo arc start, NOT high frequency, hope it reduce noise .

My plasma has as I understand pnevmo arc start, NOT high frequency, hope it reduce noise .

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11565

- Thank you received: 3882

05 Nov 2021 23:46 #225449

by rodw

Replied by rodw on topic Wiring THC A-D 300 to plasma cnc interface.

A Meanwell MDR-60-24 is probably smaller than your existing 12 volt power supply if the pictures are to go by.

I would be very surprised if your plasma cutter could not handle 24 volts through its ArcOK relay. Most handle far more than that.

Dry contact means there is no electrical connection between the relay contactors and the plasma side.

When the plasma cutter gets a good arc, it closes the relay and current flows from field power, through the relay and to an input.

Expected use is to connect field power to one of the arcOK pins and the other pin should be connected directly to an input.

I like the Mesa commx2 for field power connections.

Have you got a link to that motor and drive? It looks like its an AC drive in which case your 36V power supply is not required.

I would be very surprised if your plasma cutter could not handle 24 volts through its ArcOK relay. Most handle far more than that.

Dry contact means there is no electrical connection between the relay contactors and the plasma side.

When the plasma cutter gets a good arc, it closes the relay and current flows from field power, through the relay and to an input.

Expected use is to connect field power to one of the arcOK pins and the other pin should be connected directly to an input.

I like the Mesa commx2 for field power connections.

Have you got a link to that motor and drive? It looks like its an AC drive in which case your 36V power supply is not required.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

06 Nov 2021 01:22 - 06 Nov 2021 01:23 #225458

by bevins

Replied by bevins on topic Wiring THC A-D 300 to plasma cnc interface.

Since when does the 7i96 has built-in relays?

The 7i96 has 2 amp relays built in so using them will reduce failure points and result in a higher MTBF.

Last edit: 06 Nov 2021 01:23 by bevins.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21069

- Thank you received: 7189

06 Nov 2021 01:56 #225459

by tommylight

Replied by tommylight on topic Wiring THC A-D 300 to plasma cnc interface.

It has Solid State Relays, as far as i recall ... from reading the manual !

Please Log in or Create an account to join the conversation.

Time to create page: 0.140 seconds