Help! Stepper stalls high speed problem?

- xingfenkou3

-

Topic Author

Topic Author

- Visitor

-

23 Nov 2022 07:53 - 10 Dec 2024 16:33 #257437

by xingfenkou3

Help! Stepper stalls high speed problem? was created by xingfenkou3

First post and wish i had found this forum a few months ago

They say stepper motor suppliers love newbies

I have a Warco wm18 mill and have added a power z axis stepper but it stalls at high speed

I have set the driver to 4.2a and i think, can't remember without opening enclosure, to 1600 steps/rev

It works quite well but tends to stall at max speed especially raising the head. For info the head does have a gas strut helper

so where have i gone wrong?

They say stepper motor suppliers love newbies

I have a Warco wm18 mill and have added a power z axis stepper but it stalls at high speed

I have set the driver to 4.2a and i think, can't remember without opening enclosure, to 1600 steps/rev

It works quite well but tends to stall at max speed especially raising the head. For info the head does have a gas strut helper

so where have i gone wrong?

Last edit: 10 Dec 2024 16:33 by Aciera. Reason: Links removed

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

23 Nov 2022 09:22 #257442

by aleksamc

Replied by aleksamc on topic Help! Stepper stalls high speed problem?

I think decreasing the speed will solve your problem ...

But if seriously - you give not to much information to understand more... Attach please configuration files for your servos.

What maximum speed you have? Does steppers are configured right?

But if seriously - you give not to much information to understand more... Attach please configuration files for your servos.

What maximum speed you have? Does steppers are configured right?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

23 Nov 2022 09:45 #257443

by Clive S

Replied by Clive S on topic Help! Stepper stalls high speed problem?

I have converted 2 WM18s

In my opinion nema 17 are a bit small . I would use nema 23 with a drive that will handle at least 60V so a bigger power supply as well.

Welcome to the forum .

In my opinion nema 17 are a bit small . I would use nema 23 with a drive that will handle at least 60V so a bigger power supply as well.

Welcome to the forum .

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

23 Nov 2022 10:26 #257444

by rodw

Replied by rodw on topic Help! Stepper stalls high speed problem?

24v for motors is not enough. I learnt the hard way too. The motors are only 1.5 amps so don't exceed that.

Doubling the voltage will quadruple motor torque. Look for a 48v power supply for your stepper drivers. Say 7-10 amps

Try that first but I suspect you will need to upgrade the motors as stated earlier. At least you will have the drives and power for them.

I know a friend with a very early Syil which was based on a Seig SX3 which is a similar size. It uses a NEMA34 on the Z axis.... and NEMA 23's for X & Y

Doubling the voltage will quadruple motor torque. Look for a 48v power supply for your stepper drivers. Say 7-10 amps

Try that first but I suspect you will need to upgrade the motors as stated earlier. At least you will have the drives and power for them.

I know a friend with a very early Syil which was based on a Seig SX3 which is a similar size. It uses a NEMA34 on the Z axis.... and NEMA 23's for X & Y

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

23 Nov 2022 12:10 #257455

by tommylight

Replied by tommylight on topic Help! Stepper stalls high speed problem?

Nema 17 is to small, it says extruder motor on the link.

@RodW

Doubling voltage does not quadruple torque on stepper systems, it raises the usable high end RPM by a lot.

-

As mentioned, use a Nema 23 stepper, try to find a low inductance one, those are much better for higher speeds and can be used with 24V for most applications.

@RodW

Doubling voltage does not quadruple torque on stepper systems, it raises the usable high end RPM by a lot.

-

As mentioned, use a Nema 23 stepper, try to find a low inductance one, those are much better for higher speeds and can be used with 24V for most applications.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

25 Nov 2022 03:04 #257592

by rodw

www.geckodrive.com/support/motor-power

Where the OP is in the journey, its easier for him to increase the power supply voltage than to make new mounts for his existing motors. He will get improved performance but whether it is enough is another matter.

On my first stepper project, I used 24 volts and suffered from lost steps. Replacing the power supply with a 48 V one solved that due to increased power and torque offered,

There is a lot less work following my suggestions v's replacing motors and the higher voltage will also get better performace with NEMA23's. Long term he probably needs to do both but he might get some improvement quite easilly by changing the power supply, Who knows, that may let him machine some nice mounts for nemaa 23's too.

Replied by rodw on topic Help! Stepper stalls high speed problem?

And increases power and torque@RodW

Doubling voltage does not quadruple torque on stepper systems, it raises the usable high end RPM by a lot.

www.geckodrive.com/support/motor-power

Where the OP is in the journey, its easier for him to increase the power supply voltage than to make new mounts for his existing motors. He will get improved performance but whether it is enough is another matter.

On my first stepper project, I used 24 volts and suffered from lost steps. Replacing the power supply with a 48 V one solved that due to increased power and torque offered,

There is a lot less work following my suggestions v's replacing motors and the higher voltage will also get better performace with NEMA23's. Long term he probably needs to do both but he might get some improvement quite easilly by changing the power supply, Who knows, that may let him machine some nice mounts for nemaa 23's too.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

25 Nov 2022 10:56 #257605

by tommylight

Replied by tommylight on topic Help! Stepper stalls high speed problem?

It does not make it correct info if it is on Geckodrive website, Rod.

I am sure Marius did not write that as he knows his stuff very good.

Marius, i think that was his name, is the owner of geckodrive.

A stepper motor at 2A will have the same power and torque, no matter how many volts you provide to the drive, at standstill and low RPM.

At higher RPM it will raise the power and torque by a lot.

Induction, i always mention here to get low inductance motors as they can spin faster with lower voltages.

Vexta and Oriental have some very good videos on youtube explaining that in great detail.

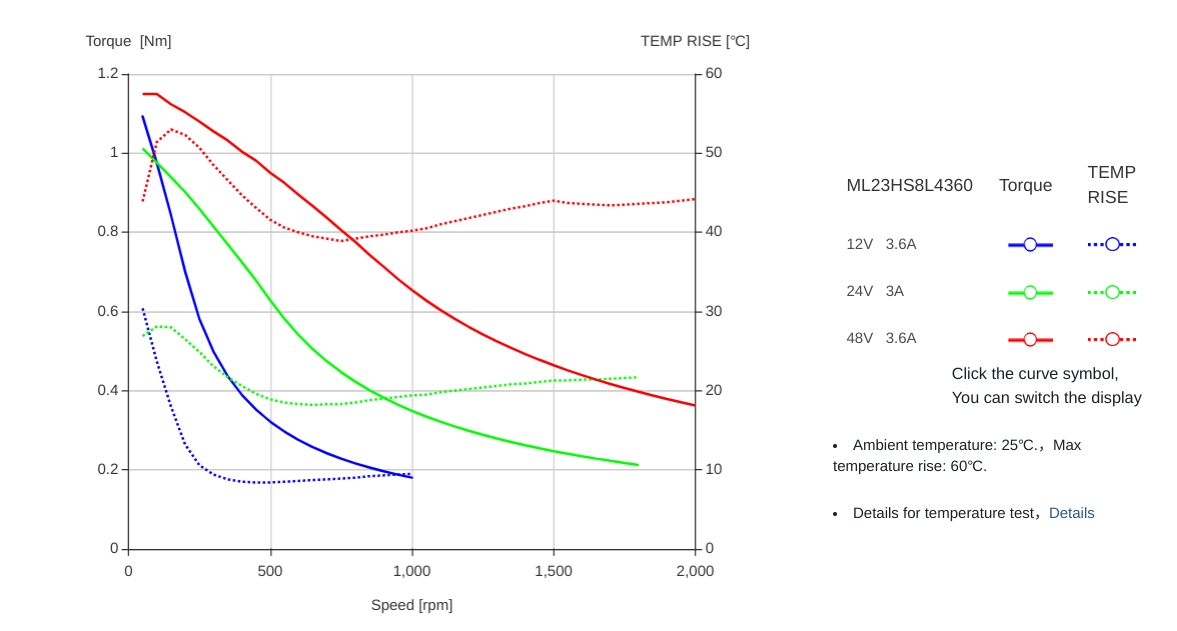

All stepper motors have torque charts, some will have those for 2 or 3 different voltages feed to the drive, it can be clearly seen how the torque remains the same at low RPM, but goes much higher at higher RPM with higher voltage.

And, higher and lower RPM in stepper systems is a relative term, some will do only 100RPM with usable torque, some 500RPM, with the same 24V and same drive. That is inductance, or visualy, a tank filling with water by a small tube, higher pressure/current = faster fill, smaller tank/inductance = faster fill, etc, etc.

I am sure Marius did not write that as he knows his stuff very good.

Marius, i think that was his name, is the owner of geckodrive.

A stepper motor at 2A will have the same power and torque, no matter how many volts you provide to the drive, at standstill and low RPM.

At higher RPM it will raise the power and torque by a lot.

Induction, i always mention here to get low inductance motors as they can spin faster with lower voltages.

Vexta and Oriental have some very good videos on youtube explaining that in great detail.

All stepper motors have torque charts, some will have those for 2 or 3 different voltages feed to the drive, it can be clearly seen how the torque remains the same at low RPM, but goes much higher at higher RPM with higher voltage.

And, higher and lower RPM in stepper systems is a relative term, some will do only 100RPM with usable torque, some 500RPM, with the same 24V and same drive. That is inductance, or visualy, a tank filling with water by a small tube, higher pressure/current = faster fill, smaller tank/inductance = faster fill, etc, etc.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

25 Nov 2022 12:37 - 25 Nov 2022 12:39 #257619

by rodw

Replied by rodw on topic Help! Stepper stalls high speed problem?

Tommy, sorry you are wrong. As you increase the voltage, the torque curve lifts as shown here for a random Moon Industries NEMA 23. Moon are an industrial quality manufacturer up there with Sanyo Denki

In this graph I added a 48 volt plot using Moon's cool customisable graphing module on the product web page. Compare that with the 24 volt plot. You will note torque has increased

www.moonsindustries.com/p/nema-23-standa...0-000004611110011248

But yes, you definitely increase the top end speed as well as torque so you can harness more of that torque with reduction gearing.

The temperature goes up by 44 deg but if you add 35 deg ambient to 44, we end up with 79 deg well below the maximum temp of 130 deg the insulation is rated to.

As a general rule, low inductance motors perform better, but I am yet to be convinced it is the best parameter to design to.

In all of the 100s of drives I benchmarked in our stepper design model that was developed over several months, inductance is definitely not relevant. Its much more important to match the rotational inertia of the system with the motor's rotational inertia. Ideally, you want a 1:1 relationship and it needs to be below 1:1 to prevent the motor from burning up. A low ratio implies the motor is underutilised (eg. too big for the application)

Take for example the amazing NEMA 24 Sanyo Denki 103H7823-5740, it has high inductance of 9.5 but a very high rotor inertia of 840 g/cm^2. I suspect the size of the rotor is the reason why this is only a 2 amp motor as there is not much room for the coil windings! But it outperforms all motors in its class. I've benchmarked it to over 60 m/min and settled on a safe 5m/sec/sec accelleration with a 30mm pinion and 3:1 motor reduction.

What I did learn with all the benchmarking I did is that design of stepper motor motion systems is complex and poorly understood. Its much easier to design servo driven motion systems.

In this graph I added a 48 volt plot using Moon's cool customisable graphing module on the product web page. Compare that with the 24 volt plot. You will note torque has increased

www.moonsindustries.com/p/nema-23-standa...0-000004611110011248

But yes, you definitely increase the top end speed as well as torque so you can harness more of that torque with reduction gearing.

The temperature goes up by 44 deg but if you add 35 deg ambient to 44, we end up with 79 deg well below the maximum temp of 130 deg the insulation is rated to.

As a general rule, low inductance motors perform better, but I am yet to be convinced it is the best parameter to design to.

In all of the 100s of drives I benchmarked in our stepper design model that was developed over several months, inductance is definitely not relevant. Its much more important to match the rotational inertia of the system with the motor's rotational inertia. Ideally, you want a 1:1 relationship and it needs to be below 1:1 to prevent the motor from burning up. A low ratio implies the motor is underutilised (eg. too big for the application)

Take for example the amazing NEMA 24 Sanyo Denki 103H7823-5740, it has high inductance of 9.5 but a very high rotor inertia of 840 g/cm^2. I suspect the size of the rotor is the reason why this is only a 2 amp motor as there is not much room for the coil windings! But it outperforms all motors in its class. I've benchmarked it to over 60 m/min and settled on a safe 5m/sec/sec accelleration with a 30mm pinion and 3:1 motor reduction.

What I did learn with all the benchmarking I did is that design of stepper motor motion systems is complex and poorly understood. Its much easier to design servo driven motion systems.

Attachments:

Last edit: 25 Nov 2022 12:39 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

25 Nov 2022 17:50 #257633

by tommylight

Replied by tommylight on topic Help! Stepper stalls high speed problem?

I am not wrong, read my post again and watch the graph, there is no change in torque at low RPM, at all, not even at 12V!

This is getting tedious, several times i said the exact same thing, it does not increase anything at low RPM, it increase everything at higher RPM.

This is getting tedious, several times i said the exact same thing, it does not increase anything at low RPM, it increase everything at higher RPM.

Please Log in or Create an account to join the conversation.

- JPL

- Offline

- Platinum Member

-

Less

More

- Posts: 337

- Thank you received: 118

25 Nov 2022 19:08 #257636

by JPL

Replied by JPL on topic Help! Stepper stalls high speed problem?

@tommylight is right

See attached document. This is the older version made by Marius from Geckodrive. The first 3 pages explains this very well.

Basically:

- Torque vs Voltage curves clearly shows that voltage is irrevelant at low speed.

- Higher supply voltage will reduce current thus I2 x R loss. This apply ONLY to higher speed.

- Double 2x voltage will generate 2x torque at higher speed (theorically, although slightly less in real application)

- Inductance is the real enemy, this is why larger motor have a torque/speed curve dropiing much faster than smaller motor.

See attached document. This is the older version made by Marius from Geckodrive. The first 3 pages explains this very well.

Basically:

- Torque vs Voltage curves clearly shows that voltage is irrevelant at low speed.

- Higher supply voltage will reduce current thus I2 x R loss. This apply ONLY to higher speed.

- Double 2x voltage will generate 2x torque at higher speed (theorically, although slightly less in real application)

- Inductance is the real enemy, this is why larger motor have a torque/speed curve dropiing much faster than smaller motor.

Attachments:

The following user(s) said Thank You: tommylight, cakeslob

Please Log in or Create an account to join the conversation.

Time to create page: 0.106 seconds