Milestone reached, but "maxvel is too big"

- Doug @ Design8Studio.com

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 45

10 Jan 2023 03:53 #261416

by Doug @ Design8Studio.com

Milestone reached, but "maxvel is too big" was created by Doug @ Design8Studio.com

I'm so pleased and excited to have reached a milestone with all motors spinning, all endstops working, and all axes homing! Estop works, and onscreen indication is that the Float Z's wiring is sound, and manual test of the Float Z switch is being detected.

Im so impressed with LinuxCNC, and the members of this forum. In my limited LinuxCNC experience so far, I am noticing that error message(s) are wonderfully descriptive, making it unusually easy to figure out what is wrong. Kudos to the amazing developers who are doing all this.

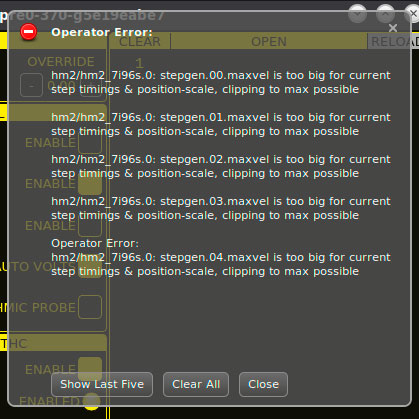

Speaking of error messages, the issue now in focus is "maxvel is too big" ...

While it's quite easy to tell what is wrong, my challenge is that I don't know how to fix it, because the skill of setting up step timings and scale is beyond my current knowledge and experience.

How I got here, is a I followed a tutorial post on the V1 Engineering forum by Kyle ( @kd2018 ) and in doing so I did some conversions of his values from inches to millimeters, because I tend to like to work in metric.

I'm in hopes that someone can point me toward a quick fix, as my long term goal of learning more about step timings etc is beyond the scope of current project.

Thanks again for being awesome!

Im so impressed with LinuxCNC, and the members of this forum. In my limited LinuxCNC experience so far, I am noticing that error message(s) are wonderfully descriptive, making it unusually easy to figure out what is wrong. Kudos to the amazing developers who are doing all this.

Speaking of error messages, the issue now in focus is "maxvel is too big" ...

While it's quite easy to tell what is wrong, my challenge is that I don't know how to fix it, because the skill of setting up step timings and scale is beyond my current knowledge and experience.

How I got here, is a I followed a tutorial post on the V1 Engineering forum by Kyle ( @kd2018 ) and in doing so I did some conversions of his values from inches to millimeters, because I tend to like to work in metric.

I'm in hopes that someone can point me toward a quick fix, as my long term goal of learning more about step timings etc is beyond the scope of current project.

Thanks again for being awesome!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11472

- Thank you received: 3848

10 Jan 2023 05:34 #261424

by rodw

Replied by rodw on topic Milestone reached, but "maxvel is too big"

These settings in your in file for each joint set these

If they are too short, the stepper pulses may not be seen, if too long, they prevent hitting MAXVEL

DIRSETUP = 2500

DIRHOLD = 2500

STEPLEN = 2500

STEPSPACE = 2500If they are too short, the stepper pulses may not be seen, if too long, they prevent hitting MAXVEL

The following user(s) said Thank You: Doug @ Design8Studio.com

Please Log in or Create an account to join the conversation.

- Doug @ Design8Studio.com

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 45

10 Jan 2023 06:25 #261427

by Doug @ Design8Studio.com

Replied by Doug @ Design8Studio.com on topic Milestone reached, but "maxvel is too big"

Thank you so much!

Please Log in or Create an account to join the conversation.

Time to create page: 0.159 seconds