- Configuring LinuxCNC

- Basic Configuration

- Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need

Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need

- Absurd

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

12 Mar 2023 21:48 - 12 Mar 2023 21:50 #266518

by Absurd

Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need was created by Absurd

Hi there,I have a self-built CNC

www.unclephil.de/volksfr%C3%A4se-vf1/

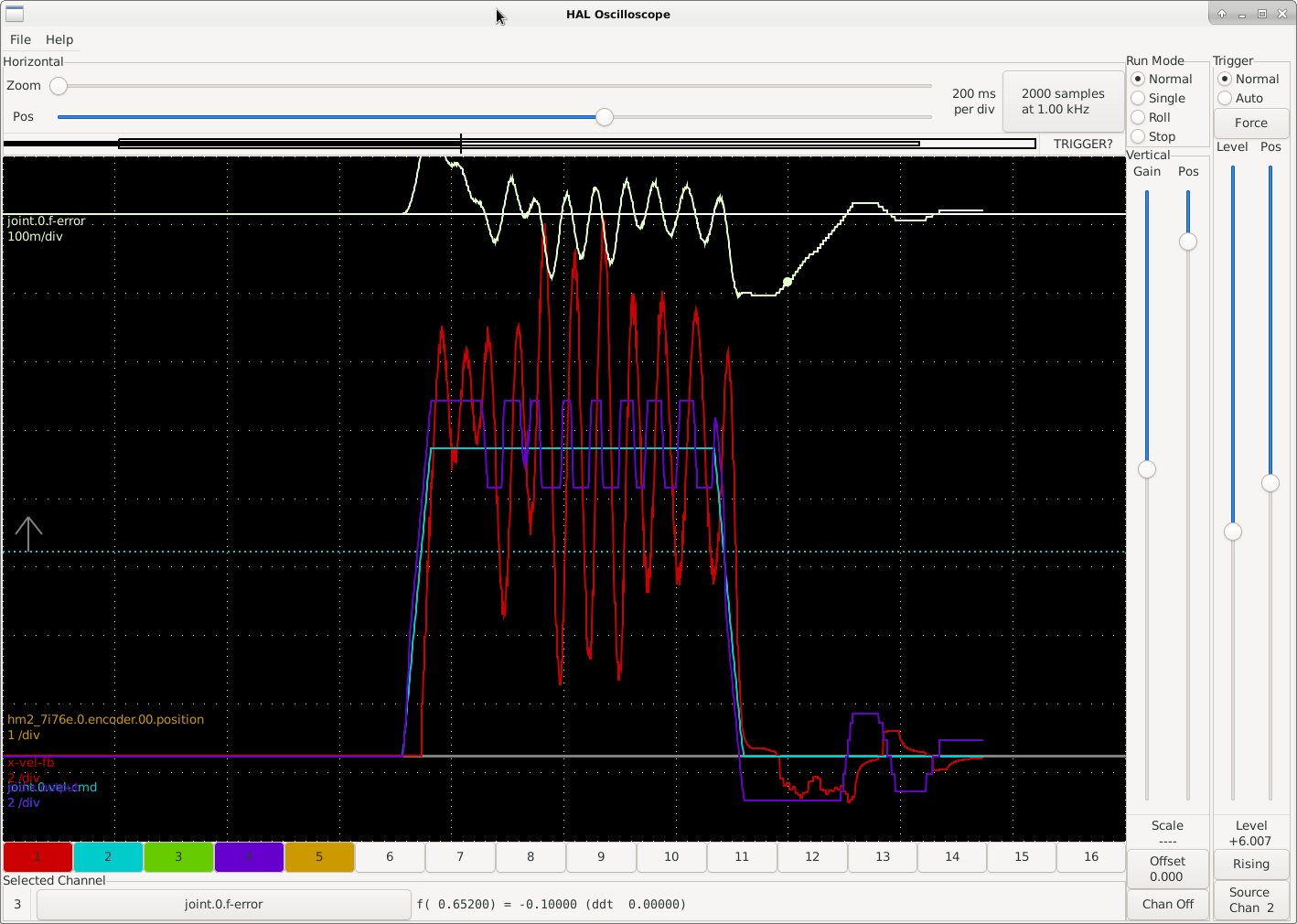

in 850x650mm. Last week, I installed glass scales and noticed strange speed oscillations on the X and Y axes (see screenshot). Both axes use timing belts and steppers set to 6400 steps per revolution. The oscillations are particularly severe at 1000mm/min and are visible. The Z-axis, which is driven by a ball screw, does not have these issues. I have attached my configurations for reference.

Here's what I have tested so far:

Here's what I have tested so far:

- Various settings (speeds and accelerations)

- Removed motor (runs normally)

- Tensioned timing belt

- Moved X-axis without the motor (moves easily)

- Checked all screws

Last edit: 12 Mar 2023 21:50 by Absurd.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11306

- Thank you received: 3785

12 Mar 2023 22:22 #266520

by rodw

Replied by rodw on topic Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need

I think its likley to be resonance from the stepper becasue you are using direct drive and from what I can work out 64mm of travel per revolution.

I initially made the same mistake.

Ref: forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

You'll see I made a 3:1 reduction that fitted where the motor was...

I initially made the same mistake.

Ref: forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

You'll see I made a 3:1 reduction that fitted where the motor was...

Please Log in or Create an account to join the conversation.

- Absurd

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

12 Mar 2023 22:42 #266522

by Absurd

Replied by Absurd on topic Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need

Thanks for your answer. If I'm not mistaken it's 90mm travel per revolution. (71 steps per mm, 6400 steps per revolution). A Higher Value would be better in this regard, right?

I ordered Ball screw mounts and Ball screws with 5mm pitch last week actually. This would be still a direct drive. Would this setup also be prone to these problems?

I ordered Ball screw mounts and Ball screws with 5mm pitch last week actually. This would be still a direct drive. Would this setup also be prone to these problems?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20393

- Thank you received: 6934

12 Mar 2023 23:40 #266523

by tommylight

Microsteps are not steps, they are small move in between the actual steps.

Direct drive for this is OK, and most machines use this way of driving.

And, no problems with this setup, no flex so no vibrations.

Replied by tommylight on topic Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need

That is utterly unusable for anything with any mass, and it is not 71 steps/mm, it is 2.2 steps/mm.Thanks for your answer. If I'm not mistaken it's 90mm travel per revolution. (71 steps per mm, 6400 steps per revolution).

Microsteps are not steps, they are small move in between the actual steps.

Of what? Microstepping? See above.A Higher Value would be better in this regard, right?

This is very usable for a mill, even 10mm pitch is still good.I ordered Ball screw mounts and Ball screws with 5mm pitch last week actually. This would be still a direct drive. Would this setup also be prone to these problems?

Direct drive for this is OK, and most machines use this way of driving.

And, no problems with this setup, no flex so no vibrations.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Basic Configuration

- Strange Speed Oscillations on X and Y Axes with Timing Belts and Steppers - Need

Time to create page: 0.098 seconds