Spindle and encoder

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

17 Aug 2023 14:18 #278264

by PCW

Replied by PCW on topic Spindle and encoder

The should be left open for single ended level signals@PCW: What is the correct way to connect single ended encoders? Should the A- B- and I- terminal on the mesa card be left floating or grounded? (Or it doesnt matter as long as the jumpers are set correctly)

The following user(s) said Thank You: JPL

Please Log in or Create an account to join the conversation.

- JPL

- Offline

- Platinum Member

-

Less

More

- Posts: 337

- Thank you received: 118

17 Aug 2023 21:34 #278304

by JPL

The very best would be for you to provide an exact diagram of the connection between the encoder, the mesa card and the pow supplies.

I think you are mixing ground with earth ground...

Ground (GND) often identify the negative side of the power supply. This can also be named common, V- or in your case -ve for the encoder. You will then connect the ground of the encoder to the -ve of the power supply AND also to the GND of the encoders on the mesa card. For the 7i96s this is pin 9 (or 15) of TB2. The ground should NOT be connected to the shield or earth ground.

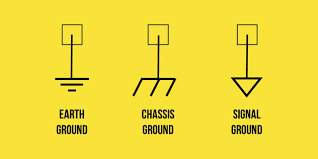

Earth ground is often identified by the (earth ground) symbol below:

Earth ground is usually connected to the chassis/frame and also ONE (and only one) side of the shield of a cable. It should NOT be connected to the ground (as defined above). The exterior of the db9 connector (shell) should be connected to earth ground, but NEVER to the ground, same for the shield of any cable. What you wrote before suggest that this is what is happening.

Replied by JPL on topic Spindle and encoder

Humm, I'm sorrry, maybe it's me but I don't understand half of what you wroteNo, because as mentioned earlier the encoder cable, male terminal block, ve- (ground) pin and other end of the cable the ve- wire is ground-off on the female DB9 exterior connector. Pardon me, I mistaken the P3 wire and ground pigtail wire when I was long-distant from my equipment earlier this morning. Actually, a pigtail is just another ground wire the male terminal block shares with the ve- pin. The pigtail probably is if the ground isn't going to the power supply and for instance to the chassis or headstock instead and reassure the ground is cycling. That's actually how Masso or Sherline made the cable. However, the ground is coming from the voltage regulator with my setup. I made a cable and the other end is ground-off on the male exterior DB9 too that connects to the female DB9 encoder cable. The P1, P2 and P3 actually are individual pins and P3 not sharing ground (common, ve-).

The very best would be for you to provide an exact diagram of the connection between the encoder, the mesa card and the pow supplies.

I think you are mixing ground with earth ground...

Ground (GND) often identify the negative side of the power supply. This can also be named common, V- or in your case -ve for the encoder. You will then connect the ground of the encoder to the -ve of the power supply AND also to the GND of the encoders on the mesa card. For the 7i96s this is pin 9 (or 15) of TB2. The ground should NOT be connected to the shield or earth ground.

Earth ground is often identified by the (earth ground) symbol below:

Earth ground is usually connected to the chassis/frame and also ONE (and only one) side of the shield of a cable. It should NOT be connected to the ground (as defined above). The exterior of the db9 connector (shell) should be connected to earth ground, but NEVER to the ground, same for the shield of any cable. What you wrote before suggest that this is what is happening.

Attachments:

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

24 Aug 2023 19:10 #278879

by smplc

Replied by smplc on topic Spindle and encoder

A 48VDC and 7.3A power supply output is inlet a voltage regulator and pot adjusted to approximately 13VDC output. The voltage regulator 13VDC and Ground connect to a circular connector with matching terminals to a cable. The other end of the cable has a DB9 and the Ground is soldered to the exterior DB9. The Masso Optical Encoder came with a provided cable and Ground already soldered similarly. The ground pigtail could be used optionally but didn't seem necessary to receive the encoder's high and low voltage.

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

24 Aug 2023 19:23 #278882

by smplc

Replied by smplc on topic Spindle and encoder

Would the Koyo TRD-SR/SHR□V of particular TRD-SR1000VD that's, radial, magnetic, differential and 1000 ppr encoder suffice as an alternative?

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

25 Aug 2023 18:55 - 25 Aug 2023 20:09 #278944

by smplc

Replied by smplc on topic Spindle and encoder

The TRD-SR1000VD output waveform max response frequency is 200kHz. Are the 7i96s and LinuxCNC operable with the TRD-SR1000VD frequency visa versa?

Last edit: 25 Aug 2023 20:09 by smplc.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21216

- Thank you received: 7246

25 Aug 2023 20:13 #278951

by tommylight

Replied by tommylight on topic Spindle and encoder

Yes.

Most Mesa boards can do up to 10 MHz, that is 10000 KHz.

Most Mesa boards can do up to 10 MHz, that is 10000 KHz.

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

25 Aug 2023 23:26 - 25 Aug 2023 23:31 #278963

by smplc

Replied by smplc on topic Spindle and encoder

Manually rotating TRD-SR1000VD encoder shaft high and low signals.

VDC digital multi-meter readings from 7i96s encoder terminal block.

Signal High Low

A+ 3.17 0.23

A- 3.16 0.21

B+ 3.16 0.22

B- 3.16 0.20

Z+ 0.23

Z- 3.17

Temporarily, I connected the TRD-SR1000VD encoder wires immediately to the 7i96s encoder terminal block including differential signals to configure and test the encoder until I made a new cable and connectors. The present cable connected to the control box is from a previous Masso encoder that uses TTL signals and is only used now during testing and for P1, P2 and P3 speed controller. The 7i96s, W1, W2 and W3 jumpers are moved to the right. Meanwhile, the encoder shaft is placed in the mini CNC lathe collet chuck before mounting on a bracket for consistent shaft rotation and initial testing.

The TRD-SR1000VD encoder is 1000 PPR and radial. Unsure if magnetic but generally radial is magnetic. The encoder at steady rotation the PyVCP and Hal Meter RPM are fairly accurate readings with the portable tachometer but the commanded RPM isn't and considerably partially due to the pulley ratio. Is the PncConfig Wizard not calculating the max spindle and pulley ratio and PWM of 10V to the commanded RPM? The PyVCP and Hal Meter RPM are twitchy at a tenths and ten-thousandths decimal places during rotation but when no rotation both RPMs remain at a stable 0. Could the RPM be rounded to the nearest whole number to prevent twitching? The encoder at steady RPM and the Hal Scope , A and B channels aren't quite 90 degrees out. Should and can the signals be nearer 90 degrees out and more square at low to medium RPM with this encoder and how?

VDC digital multi-meter readings from 7i96s encoder terminal block.

Signal High Low

A+ 3.17 0.23

A- 3.16 0.21

B+ 3.16 0.22

B- 3.16 0.20

Z+ 0.23

Z- 3.17

Temporarily, I connected the TRD-SR1000VD encoder wires immediately to the 7i96s encoder terminal block including differential signals to configure and test the encoder until I made a new cable and connectors. The present cable connected to the control box is from a previous Masso encoder that uses TTL signals and is only used now during testing and for P1, P2 and P3 speed controller. The 7i96s, W1, W2 and W3 jumpers are moved to the right. Meanwhile, the encoder shaft is placed in the mini CNC lathe collet chuck before mounting on a bracket for consistent shaft rotation and initial testing.

The TRD-SR1000VD encoder is 1000 PPR and radial. Unsure if magnetic but generally radial is magnetic. The encoder at steady rotation the PyVCP and Hal Meter RPM are fairly accurate readings with the portable tachometer but the commanded RPM isn't and considerably partially due to the pulley ratio. Is the PncConfig Wizard not calculating the max spindle and pulley ratio and PWM of 10V to the commanded RPM? The PyVCP and Hal Meter RPM are twitchy at a tenths and ten-thousandths decimal places during rotation but when no rotation both RPMs remain at a stable 0. Could the RPM be rounded to the nearest whole number to prevent twitching? The encoder at steady RPM and the Hal Scope , A and B channels aren't quite 90 degrees out. Should and can the signals be nearer 90 degrees out and more square at low to medium RPM with this encoder and how?

Last edit: 25 Aug 2023 23:31 by smplc.

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

26 Aug 2023 04:22 #278983

by smplc

Replied by smplc on topic Spindle and encoder

Is another oscilloscope suggestible, free software and Linux download to recheck the encoder signals without probing the terminals?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

26 Aug 2023 04:44 #278986

by PCW

Replied by PCW on topic Spindle and encoder

As long as the encoder has valid quadrature so counts correctly

I would not worry about it.

You can filter the displayed RPM to eliminate most flicker

I would not worry about it.

You can filter the displayed RPM to eliminate most flicker

Please Log in or Create an account to join the conversation.

- smplc

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 224

- Thank you received: 1

26 Aug 2023 05:30 #278989

by smplc

Replied by smplc on topic Spindle and encoder

The encoder is calibrated and fixed within its enclosure. The 1000 PPR is per specification and attachment six replies ago.

Is the filter at the .ini file and create or edit a variable? How is it done?

The GUI RPM and portable tachometer readings are about equivalent. However, the commanded (MDI) RPM isn't. How's the commanded RPM adjusted to the actual RPM?

Is the RPM coming from the A and B signals or the Z signal of the encoder?

Is the filter at the .ini file and create or edit a variable? How is it done?

The GUI RPM and portable tachometer readings are about equivalent. However, the commanded (MDI) RPM isn't. How's the commanded RPM adjusted to the actual RPM?

Is the RPM coming from the A and B signals or the Z signal of the encoder?

Please Log in or Create an account to join the conversation.

Time to create page: 0.112 seconds