- Configuring LinuxCNC

- Basic Configuration

- 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 00:25 #311907

by flyingbrick

7i97T with Mesa CT- Desn't seem to be outputting an analogue signal. was created by flyingbrick

Hi all.I have taken a look through the forums here and had a heavy google search- I had a few leads but all parts of my code appear OK where others seem to have failed.I was trying to identify if it was my drives not responding to signal, my wiring being incomplete, or my HAL setup.. could be all of them but I am unable to pick up any output from the mesa board via multimeter or drive monitoring software.Please see attached- any assistance very much appreciated.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

13 Oct 2024 00:55 #311912

by tommylight

Replied by tommylight on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

There is nothing regarding spindle in those files, except the ON pin.

Try again or edit this but do check if the spindle stuff is checked in the wizard.

Try again or edit this but do check if the spindle stuff is checked in the wizard.

The following user(s) said Thank You: flyingbrick

Please Log in or Create an account to join the conversation.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 01:03 #311914

by flyingbrick

Replied by flyingbrick on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

Correct - there was no way of configuring the spindle using my card and mesa CT - But that was a hurdle to jump another day  it should still work tho right? Or does it NEED spindle??

it should still work tho right? Or does it NEED spindle??

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

13 Oct 2024 05:01 #311924

by PCW

Replied by PCW on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

When linuxcnc is running and you expect an analog output

can you run:

halcmd show all > all.txt

in a terminal window and port all.txt here?

can you run:

halcmd show all > all.txt

in a terminal window and port all.txt here?

Please Log in or Create an account to join the conversation.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 05:21 #311925

by flyingbrick

Replied by flyingbrick on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

Hi PCW.

Attached. I cant do it while actually trying to generate an output as it errors within a moment due to movement error

Attached. I cant do it while actually trying to generate an output as it errors within a moment due to movement error

Please Log in or Create an account to join the conversation.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 05:24 - 13 Oct 2024 05:34 #311926

by flyingbrick

Replied by flyingbrick on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

edit to clarify.

When i look at halconfig and PWM enable and value,

00 and 01 enable when i turn on the machine within lcnc

I can jog X and get 00 to flash up a value. 01 and 02 do not do this (02 probably because its not enabled)

When i look at halconfig and PWM enable and value,

00 and 01 enable when i turn on the machine within lcnc

I can jog X and get 00 to flash up a value. 01 and 02 do not do this (02 probably because its not enabled)

Last edit: 13 Oct 2024 05:34 by flyingbrick.

Please Log in or Create an account to join the conversation.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 05:28 #311927

by flyingbrick

Replied by flyingbrick on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

Dont know what went wrong with that last one.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

13 Oct 2024 14:45 - 13 Oct 2024 14:55 #311971

by PCW

Replied by PCW on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

None of the PWM enables are true (and all PWM values are 0)

So no analog output is possible:

30 bit IN FALSE hm2_7i97.0.pwmgen.00.enable <== joint-0-enable

30 float IN 0 hm2_7i97.0.pwmgen.00.value <== joint.0.output

30 bit IN FALSE hm2_7i97.0.pwmgen.01.enable <== joint-1-enable

30 float IN 0 hm2_7i97.0.pwmgen.01.value <== joint.1.output

30 bit IN FALSE hm2_7i97.0.pwmgen.02.enable <== joint-2-enable

30 float IN 0 hm2_7i97.0.pwmgen.02.value <== joint.2.output

30 bit IN FALSE hm2_7i97.0.pwmgen.03.enable

30 float IN 0 hm2_7i97.0.pwmgen.03.value

30 bit IN FALSE hm2_7i97.0.pwmgen.04.enable

30 float IN 0 hm2_7i97.0.pwmgen.04.value

30 bit IN FALSE hm2_7i97.0.pwmgen.05.enable

30 float IN 0 hm2_7i97.0.pwmgen.05.value

30 s32 OUT 0 hm2_7i97.0.read-request.time

30 s32 OUT 134983 hm2_7i97.0.read.time

Note that on initial setup of analog servos you will need to widen the following error limits

as you will likely trigger an immediate following error with such narrow limits

I would start with say 10 mm for FERROR and MIN_FERROR. You may also find that

you get an instant runaway because the feedback polarity is backwards.

YOu fix the by reversing the sign of the PWM scale

So no analog output is possible:

30 bit IN FALSE hm2_7i97.0.pwmgen.00.enable <== joint-0-enable

30 float IN 0 hm2_7i97.0.pwmgen.00.value <== joint.0.output

30 bit IN FALSE hm2_7i97.0.pwmgen.01.enable <== joint-1-enable

30 float IN 0 hm2_7i97.0.pwmgen.01.value <== joint.1.output

30 bit IN FALSE hm2_7i97.0.pwmgen.02.enable <== joint-2-enable

30 float IN 0 hm2_7i97.0.pwmgen.02.value <== joint.2.output

30 bit IN FALSE hm2_7i97.0.pwmgen.03.enable

30 float IN 0 hm2_7i97.0.pwmgen.03.value

30 bit IN FALSE hm2_7i97.0.pwmgen.04.enable

30 float IN 0 hm2_7i97.0.pwmgen.04.value

30 bit IN FALSE hm2_7i97.0.pwmgen.05.enable

30 float IN 0 hm2_7i97.0.pwmgen.05.value

30 s32 OUT 0 hm2_7i97.0.read-request.time

30 s32 OUT 134983 hm2_7i97.0.read.time

Note that on initial setup of analog servos you will need to widen the following error limits

as you will likely trigger an immediate following error with such narrow limits

I would start with say 10 mm for FERROR and MIN_FERROR. You may also find that

you get an instant runaway because the feedback polarity is backwards.

YOu fix the by reversing the sign of the PWM scale

Last edit: 13 Oct 2024 14:55 by PCW.

The following user(s) said Thank You: flyingbrick

Please Log in or Create an account to join the conversation.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 20:20 #312004

by flyingbrick

Replied by flyingbrick on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

Thanks tons PCW,

halcmd show all > all.txt is an excellent tool, and your explanations are brilliant.

Its taking me a while to figure out what each item does and what we are achieving but the cogs are starting to mesh in my brain :-D

I might have to finish work early today and do some more digging.

Thanks again,

halcmd show all > all.txt is an excellent tool, and your explanations are brilliant.

Its taking me a while to figure out what each item does and what we are achieving but the cogs are starting to mesh in my brain :-D

I might have to finish work early today and do some more digging.

Thanks again,

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- flyingbrick

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 14

13 Oct 2024 21:05 - 13 Oct 2024 21:09 #312006

by flyingbrick

Replied by flyingbrick on topic 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

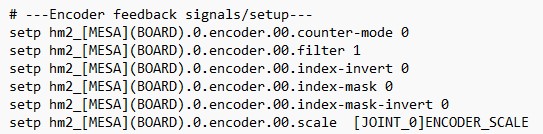

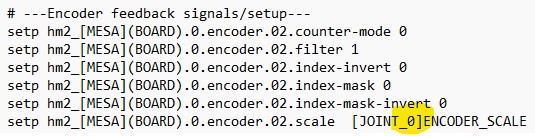

Hi PCW.

I believe I have found an error in the mesaCT's hal file... but I could be wrong (I have just been comparing axis and trying to figure out how these files work)

Can you confirm that the highlighted joint reference is wrong

This is X Axis, joint 00

And this is Z Axis, joint 02. Should the highlighted say 2 rather than 0?

Edit. If the highlighted is wrong, looks like Mesa CT was correct for joint 00 but it has this error for joints 01 and 02, for PWM scale and Encoder scale.

I believe I have found an error in the mesaCT's hal file... but I could be wrong (I have just been comparing axis and trying to figure out how these files work)

Can you confirm that the highlighted joint reference is wrong

This is X Axis, joint 00

And this is Z Axis, joint 02. Should the highlighted say 2 rather than 0?

Edit. If the highlighted is wrong, looks like Mesa CT was correct for joint 00 but it has this error for joints 01 and 02, for PWM scale and Encoder scale.

Attachments:

Last edit: 13 Oct 2024 21:09 by flyingbrick.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Basic Configuration

- 7i97T with Mesa CT- Desn't seem to be outputting an analogue signal.

Time to create page: 0.161 seconds