Lathe spindle index only?

- 109jb

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 15

04 Mar 2025 16:32 #323158

by 109jb

Lathe spindle index only? was created by 109jb

I have tried searching but cannot seem to find what I'm looking for. I am getting ready to convert my little 9x20 lathe to CNC and am trying to find out if lathe threading can be done with a single index pulse only. Basically I would make an index plat with only one hole in it and use an optical sensor for the trigger. Is this possible in LinuxCNC, and could anyone point me to an example?

Thanks,

John Brannen

Thanks,

John Brannen

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4660

- Thank you received: 2078

05 Mar 2025 19:00 #323304

by Aciera

Replied by Aciera on topic Lathe spindle index only?

An index pulse alone is not enough you also need a pulse train signal like an encoder channel to track the spindle velocity:

linuxcnc.org/docs/html/examples/spindle.html

linuxcnc.org/docs/html/examples/spindle.html

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

05 Mar 2025 19:12 - 05 Mar 2025 19:13 #323306

by PCW

Replied by PCW on topic Lathe spindle index only?

It has been done (using interpolated position) but depends on very good

speed control of the spindle vs load, since you are essentially "flying blind"

for 1 whole turn.

With the software encoder you would connect the external index pin

to both 'A' and 'index' of the encoder component and set the encoder

component to counter mode.

A small improvement to deal with just one sensor would be to have a 1/2 disk

so you can get 2 counts per turn.

speed control of the spindle vs load, since you are essentially "flying blind"

for 1 whole turn.

With the software encoder you would connect the external index pin

to both 'A' and 'index' of the encoder component and set the encoder

component to counter mode.

A small improvement to deal with just one sensor would be to have a 1/2 disk

so you can get 2 counts per turn.

Last edit: 05 Mar 2025 19:13 by PCW.

Please Log in or Create an account to join the conversation.

- jtrantow

- Offline

- Premium Member

-

Less

More

- Posts: 140

- Thank you received: 22

06 Mar 2025 05:41 - 06 Mar 2025 05:47 #323331

by jtrantow

Replied by jtrantow on topic Lathe spindle index only?

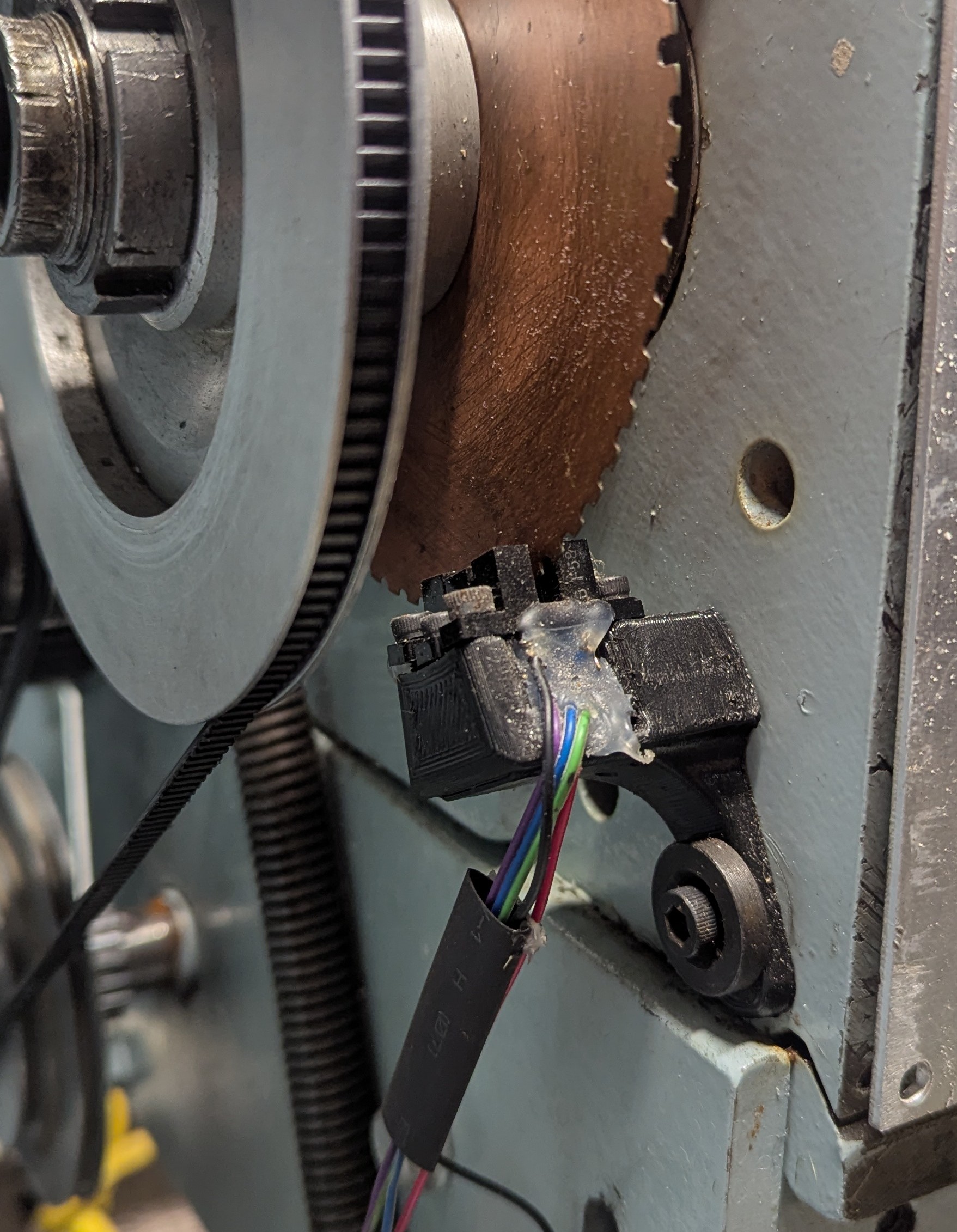

For my 9x20 spindle, I used optical sensors and cut 65 teeth into a thin disk. With two carefully offset sensors I get 260 quadrature counts and haven't had any problems threading 120-150 rpm. A third optical sensor provides the index from a deeper tooth.

I ordered an omron encoder off eBay ($20) that will be a lot cleaner. When I get around to installing it I will probably 3d print gears for a small belt running around spindle and encoder. If you go this route don't go over board on pulses per revolution. 1024 ppr will be more than enough for threading.

The most difficult part of my 9x20 conversion was the modifications to fit a small ball screw under the cross slide good luck!

I ordered an omron encoder off eBay ($20) that will be a lot cleaner. When I get around to installing it I will probably 3d print gears for a small belt running around spindle and encoder. If you go this route don't go over board on pulses per revolution. 1024 ppr will be more than enough for threading.

The most difficult part of my 9x20 conversion was the modifications to fit a small ball screw under the cross slide good luck!

Last edit: 06 Mar 2025 05:47 by jtrantow. Reason: Adder

Please Log in or Create an account to join the conversation.

- jpg

- Offline

- Premium Member

-

Less

More

- Posts: 105

- Thank you received: 13

06 Mar 2025 12:59 - 06 Mar 2025 13:04 #323349

by jpg

Replied by jpg on topic Lathe spindle index only?

Last edit: 06 Mar 2025 13:04 by jpg.

Please Log in or Create an account to join the conversation.

- 109jb

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 15

06 Mar 2025 20:35 #323366

by 109jb

Replied by 109jb on topic Lathe spindle index only?

Thanks for the reply PCW. I guess I will go with a system that has an index and also at least some number of pulses per rev on an additional channel.

Please Log in or Create an account to join the conversation.

- 109jb

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 15

06 Mar 2025 20:43 #323367

by 109jb

Replied by 109jb on topic Lathe spindle index only?

jtrantow - Good to hear from someone with the same hardware to convert. I think what I will try first is a slotted disk with as many slots as I can reasonably fit on it with one deeper slot and 2 optical slot detectors. It may wind up less slots than you have and since I would only have one detector reading them, I will have less counts per rev but will see how it goes. I like the idea of the slot detectors because they don't have any moving mechanical parts like a rotary encoder. It should also be less involved to implement than a rotary with the sprockets, belts, brackets etc. Maybe I'll wind up with a rotary but I'm going to give this a try.

Thanks Again.

Thanks Again.

Please Log in or Create an account to join the conversation.

- 109jb

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 15

06 Mar 2025 20:51 #323369

by 109jb

Replied by 109jb on topic Lathe spindle index only?

Oh. Forgot to mention. I got a 12mm ballscrew for the cross slide. Hoping it is small enough to make it work.

Please Log in or Create an account to join the conversation.

- jtrantow

- Offline

- Premium Member

-

Less

More

- Posts: 140

- Thank you received: 22

07 Mar 2025 15:48 #323426

by jtrantow

Replied by jtrantow on topic Lathe spindle index only?

You can get a quadrature signal using the same slots and offsetting another detector approx 1/2 the spacing. It can be a little finicky to adjust but gives you 4x resolution and lets you track direction too. ( Important if you want to use spindle like a dividing head)

I added another detector to pick up index, missing tooth should be fine.

I expect the omron install will be a lot easier. I could probably just wrap a belt around the spindle shaft. The omron encoder spins with imperceptible drag to the spindle just about any belt or string is enough to spin it. I also have an omron encoder that I can position on my mill drawbar for rigid tapping. Janky but functional. It worked with a rubber band while I waited for a gt2 belt. After the mill install I ordered another for lathe but haven't gotten around to installing it.

I added another detector to pick up index, missing tooth should be fine.

I expect the omron install will be a lot easier. I could probably just wrap a belt around the spindle shaft. The omron encoder spins with imperceptible drag to the spindle just about any belt or string is enough to spin it. I also have an omron encoder that I can position on my mill drawbar for rigid tapping. Janky but functional. It worked with a rubber band while I waited for a gt2 belt. After the mill install I ordered another for lathe but haven't gotten around to installing it.

Please Log in or Create an account to join the conversation.

- jtrantow

- Offline

- Premium Member

-

Less

More

- Posts: 140

- Thank you received: 22

07 Mar 2025 16:13 - 07 Mar 2025 16:15 #323431

by jtrantow

Replied by jtrantow on topic Lathe spindle index only?

Attachments:

Last edit: 07 Mar 2025 16:15 by jtrantow.

Please Log in or Create an account to join the conversation.

Time to create page: 0.276 seconds