Lathe spindle index only?

- jtrantow

- Offline

- Premium Member

-

Less

More

- Posts: 140

- Thank you received: 22

07 Mar 2025 16:34 #323433

by jtrantow

Replied by jtrantow on topic Lathe spindle index only?

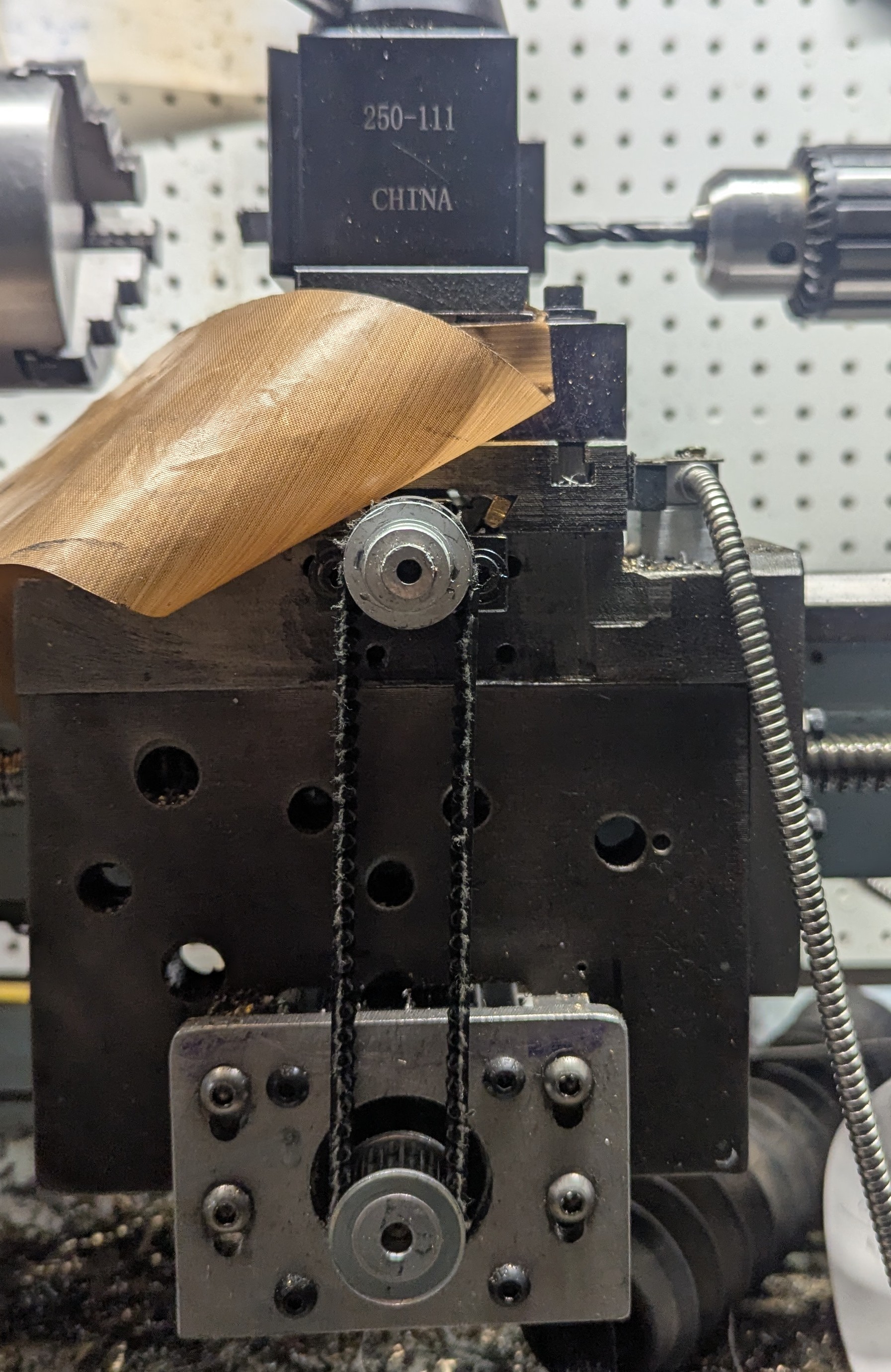

The problem I had was fitting the x ballnut under the cross slide. I ordered a 8mm ballscrew (AliExpress) and still ended up grinding off part of the nut and milling the cross slide. If you grind a ballnut with plastic ball returns use cooling or you can melt the returns...

After some trial and error, I settled on 1u magnetic encoder for x.

Photo also shows crude but effective solid tool post. You can sell all your now unnecessary lathe parts on eBay. You will never go back to change gears or manual dials. No regrets selling my compound. Use the $ for x encoder and tooling.

Finally get Andy's lathe macros working and I use the wired Logitech keypad on all my machines for jogging.

After some trial and error, I settled on 1u magnetic encoder for x.

Photo also shows crude but effective solid tool post. You can sell all your now unnecessary lathe parts on eBay. You will never go back to change gears or manual dials. No regrets selling my compound. Use the $ for x encoder and tooling.

Finally get Andy's lathe macros working and I use the wired Logitech keypad on all my machines for jogging.

Attachments:

Please Log in or Create an account to join the conversation.

- 109jb

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 15

07 Mar 2025 18:00 #323444

by 109jb

Replied by 109jb on topic Lathe spindle index only?

Thanks again. Initially I plan to do this using a Raspberry Pi using software stepping through GPIO, so I am a bit concerned about the Pi being able to keep up with encoder pulses. If it doesn't work on just the Pi, I will get a 7C81 Mesa board for it, but want to try using just the Pi first.

I don't ever see needing to use the spindle as a dividing head. I have a 4th axis on my mill if I need that, so I think two encoders, one for index and one for pulses would work okay for what I need. We will see.

Looking at your picture, that is almost exactly what I was picturing for the slot sensor mounting. I may try a 3d printed slot wheel. We'll see if it flys apart, but I generally don't run too high speeds and think it will be fine. I'll print it at 100% infill and make an aluminum hub to sanwich behind the pulley.

What brought this about is that the threading nut setup on the lathe broke last time I needed to thread a part and I figured it was time to convert to CNC. I plan to include 2 MPG handwheels mounted on the carriage so that I can mimick a manual machine for times when I just want to do simple turning. I have that worked out on the Pi already. I use a handheld wireless MPG on my mill but am thinking about adding 3 handweels and eliminating the wireless MPG. I've had a few loss of connection issues with it in the past.

This is a long term project so things won't happen too fast. I have access to a friends 13" Clausing lathe if I need one and he is only about 3minutes away. I have another big project I'm working on and this one is a fill in for times when I need a break from that one. Thinking about the basic X-Z conversion, the Z axis looks like a piece of cake, and if that 12mm ballscrew I got fits, the X axis cross slide won't be too bad either.

Thanks again.

I don't ever see needing to use the spindle as a dividing head. I have a 4th axis on my mill if I need that, so I think two encoders, one for index and one for pulses would work okay for what I need. We will see.

Looking at your picture, that is almost exactly what I was picturing for the slot sensor mounting. I may try a 3d printed slot wheel. We'll see if it flys apart, but I generally don't run too high speeds and think it will be fine. I'll print it at 100% infill and make an aluminum hub to sanwich behind the pulley.

What brought this about is that the threading nut setup on the lathe broke last time I needed to thread a part and I figured it was time to convert to CNC. I plan to include 2 MPG handwheels mounted on the carriage so that I can mimick a manual machine for times when I just want to do simple turning. I have that worked out on the Pi already. I use a handheld wireless MPG on my mill but am thinking about adding 3 handweels and eliminating the wireless MPG. I've had a few loss of connection issues with it in the past.

This is a long term project so things won't happen too fast. I have access to a friends 13" Clausing lathe if I need one and he is only about 3minutes away. I have another big project I'm working on and this one is a fill in for times when I need a break from that one. Thinking about the basic X-Z conversion, the Z axis looks like a piece of cake, and if that 12mm ballscrew I got fits, the X axis cross slide won't be too bad either.

Thanks again.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

07 Mar 2025 20:46 #323463

by andypugh

Replied by andypugh on topic Lathe spindle index only?

There is a whole thread on this subject on CNCzone, here is a description of my solution.

www.cnczone.com/forums/mini-lathe/63621-cnc.html#post509784

But it was a long time ago and all the images have bitrotted...

There are some pics of the machine here, but not the critical ones:

photos.app.goo.gl/nwM9Ze59j3zi5TB77

The basic idea is to have a T2.5 pulley small enough to fit under the cross-slide, and next to that a needle roller bearing running on a plain section of the ballscrew. Then the thrust control is handled much closer to the operator, in the micrometer dial housing, with a pair of angular contact bearings, where there is a lot more diameter to play with.

www.cnczone.com/forums/mini-lathe/63621-cnc.html#post509784

But it was a long time ago and all the images have bitrotted...

There are some pics of the machine here, but not the critical ones:

photos.app.goo.gl/nwM9Ze59j3zi5TB77

The basic idea is to have a T2.5 pulley small enough to fit under the cross-slide, and next to that a needle roller bearing running on a plain section of the ballscrew. Then the thrust control is handled much closer to the operator, in the micrometer dial housing, with a pair of angular contact bearings, where there is a lot more diameter to play with.

Please Log in or Create an account to join the conversation.

- timo

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 50

08 Mar 2025 08:25 - 08 Mar 2025 08:30 #323500

by timo

Replied by timo on topic Lathe spindle index only?

I think at the end making your own encoder is similar effort like mounting a small timing belt.

Unfortunately hollow shaft encoders are much more expensive than the required parts. (timing pulleys, small timing belt and cheap encoder)

Maybe I should try ordering a slotted disc from a PCB maker for 2USD? They do drilling and milling and it is a matter of sending them the correct pcb file.

Unfortunately hollow shaft encoders are much more expensive than the required parts. (timing pulleys, small timing belt and cheap encoder)

Maybe I should try ordering a slotted disc from a PCB maker for 2USD? They do drilling and milling and it is a matter of sending them the correct pcb file.

Last edit: 08 Mar 2025 08:30 by timo.

Please Log in or Create an account to join the conversation.

- jtrantow

- Offline

- Premium Member

-

Less

More

- Posts: 140

- Thank you received: 22

08 Mar 2025 15:08 #323526

by jtrantow

Replied by jtrantow on topic Lathe spindle index only?

I converted my lathe from parallel port to mesa when I added linear encoders. Prior to that, I had zero problems threading with the parallel port using this 65 tooth, 260 count disk using a quadrature software encoder on an ancient PC. I only used the spindle encoder for threading (<150RPM) so I'm not sure what the limit for this setup was. I still run 4 identical ancient PCs for my LCNC machines but they all have mesa cards now.

3d printed timing pulleys are a great low cost solution for the low load timing application.

The slotted disk (I used thin copper coated pc board I had laying around) is easy if you have a working CNC router or mill. The finicky part for me was aligning the sensors to the teeth. To get quadrature and index signals all three encoders need to be positioned just right.

I mounted my ballscrew bearing block directly to the apron. (original mount was damaged) This gives me just enough room for a 12 or 13T timing pulley to pass under the X slide. I may have modified the bearing block for clearance. When you remove all the manual clutter, there is room to mount the x stepper directly underneath so you end up with a shortened x axis that doesn't get in your way.

I used a wireless MPG for a while but found the joypad was much better for jogging and feeding at a consistent rate and I use MDI when I need precise movements anyway. As a bonus, it's easy to cut a nice 45 degree chamfer using the analog stick!

3d printed timing pulleys are a great low cost solution for the low load timing application.

The slotted disk (I used thin copper coated pc board I had laying around) is easy if you have a working CNC router or mill. The finicky part for me was aligning the sensors to the teeth. To get quadrature and index signals all three encoders need to be positioned just right.

I mounted my ballscrew bearing block directly to the apron. (original mount was damaged) This gives me just enough room for a 12 or 13T timing pulley to pass under the X slide. I may have modified the bearing block for clearance. When you remove all the manual clutter, there is room to mount the x stepper directly underneath so you end up with a shortened x axis that doesn't get in your way.

I used a wireless MPG for a while but found the joypad was much better for jogging and feeding at a consistent rate and I use MDI when I need precise movements anyway. As a bonus, it's easy to cut a nice 45 degree chamfer using the analog stick!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

08 Mar 2025 23:10 #323543

by andypugh

Replied by andypugh on topic Lathe spindle index only?

One option might be an engine crank encoder:Unfortunately hollow shaft encoders are much more expensive than the required parts

The following user(s) said Thank You: tommylight, Clive S, timo

Please Log in or Create an account to join the conversation.

- 109jb

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 15

09 Mar 2025 02:17 #323552

by 109jb

Replied by 109jb on topic Lathe spindle index only?

For the cross slide I oredered a 12mm ballscrew. If I can find room I will mount the ball nut under the cross slide table. If not, the screw I bought is long enough that I could mount the ballscrew on the back side of the cross slide table.

I'll be going out of town for a couple weeks, but when I get back I think I will do some examining for the encoder situation.

I saw a video of somone doing threading on linuxCNC using a missing tooth scheme. I may look into this more when I bored in my hotel room next week.

Thanks again for the comments

I'll be going out of town for a couple weeks, but when I get back I think I will do some examining for the encoder situation.

I saw a video of somone doing threading on linuxCNC using a missing tooth scheme. I may look into this more when I bored in my hotel room next week.

Thanks again for the comments

Please Log in or Create an account to join the conversation.

Time to create page: 0.153 seconds