CNC lathe to grinder.

- TheTinkeringMechanic1

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 3

07 Jun 2025 16:28 - 07 Jun 2025 19:42 #329883

by TheTinkeringMechanic1

CNC lathe to grinder. was created by TheTinkeringMechanic1

Greetings. At my work place, we recently acquired a CNC converted lathe running Knuth LinuxCNC 3.4.6.

There's a few changes we need to make for it to suit our needs. First was to set it so it would home near the chuck. I already moved the homing dogs and the limit switch orientations corrected the saddle direction so it homes out near the chuck as desired. I do understand this homing orientation is the opposite of what's commonly done on a lathe. The reason for this is the lathe is being converted into a grinder for urethane rollers. In this case we need to have the saddle home near the chuck to prevent having to move (or crash into) the tail stock so it can home every time we need to home it. We're replacing the chuck with a collet head with an internal stop for repeatability (provided our cores are to the desired spec, but that's another story)

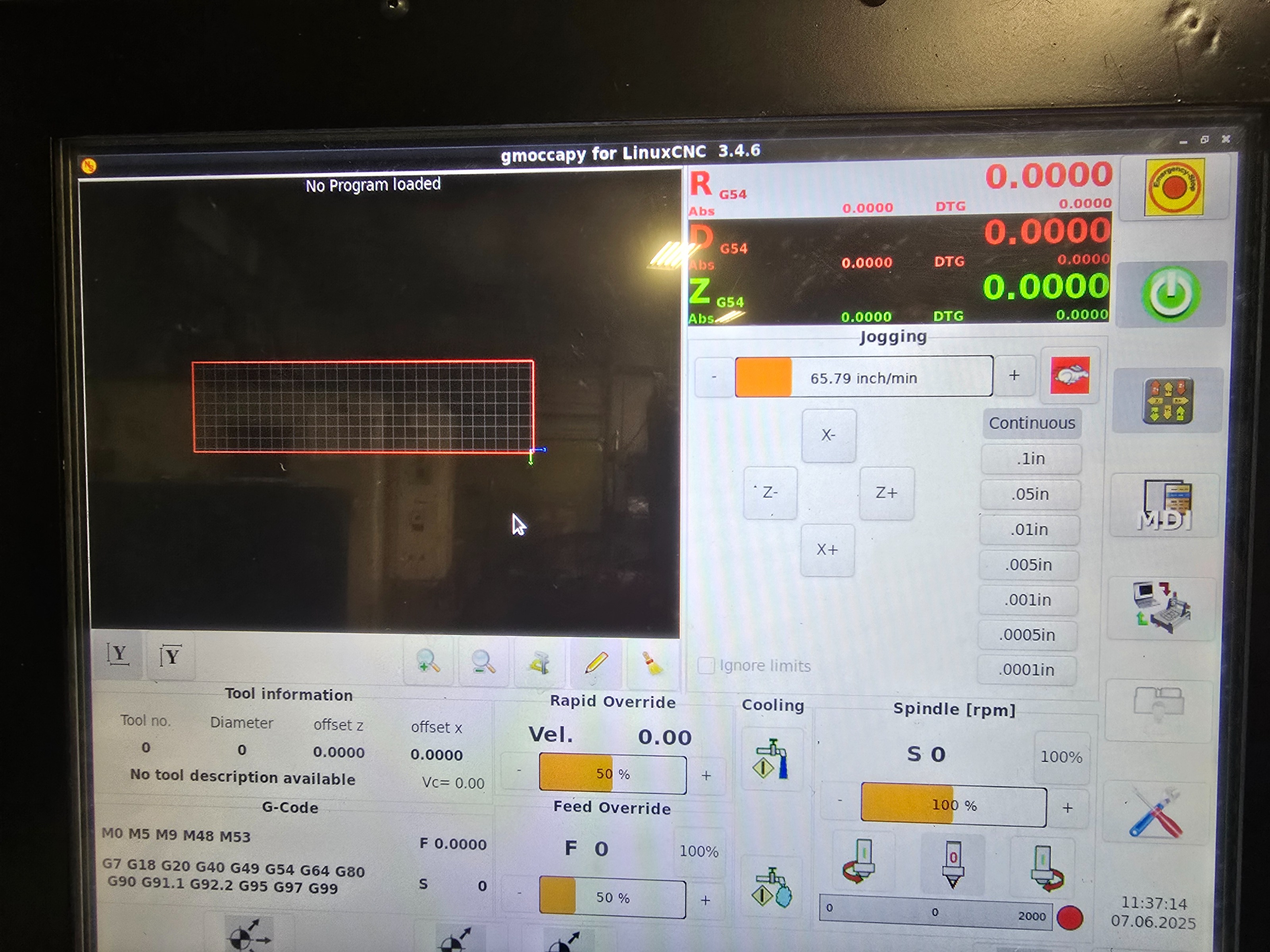

I'm still familiarizing myself with LinuxCNC and despite my best efforts so far, I seem to have hit a wall. The issue I have is although I have it set to home safely near the chuck side, in the preview grid the position marker moves in the opposite direction. The saddle moves right the marker in preview moves left. Prior to setting XZ to X-Z it would try to travel off the grid altogether and soft stop would attempt to prevent it from moving beyond the preview boarder. You can see it in the image I attached how X & Z are positioned near the lower right of the grid. Is there a way to get the preview to place Z on lower left of the grid?

Thanks in advance.

There's a few changes we need to make for it to suit our needs. First was to set it so it would home near the chuck. I already moved the homing dogs and the limit switch orientations corrected the saddle direction so it homes out near the chuck as desired. I do understand this homing orientation is the opposite of what's commonly done on a lathe. The reason for this is the lathe is being converted into a grinder for urethane rollers. In this case we need to have the saddle home near the chuck to prevent having to move (or crash into) the tail stock so it can home every time we need to home it. We're replacing the chuck with a collet head with an internal stop for repeatability (provided our cores are to the desired spec, but that's another story)

I'm still familiarizing myself with LinuxCNC and despite my best efforts so far, I seem to have hit a wall. The issue I have is although I have it set to home safely near the chuck side, in the preview grid the position marker moves in the opposite direction. The saddle moves right the marker in preview moves left. Prior to setting XZ to X-Z it would try to travel off the grid altogether and soft stop would attempt to prevent it from moving beyond the preview boarder. You can see it in the image I attached how X & Z are positioned near the lower right of the grid. Is there a way to get the preview to place Z on lower left of the grid?

Thanks in advance.

Attachments:

Last edit: 07 Jun 2025 19:42 by TheTinkeringMechanic1. Reason: Typo.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4615

- Thank you received: 2042

07 Jun 2025 17:35 #329886

by Aciera

Replied by Aciera on topic CNC lathe to grinder.

If you change your home position then you will also need to change the limit values for the axis/joint in question.

If unsure please post your ini file.

If unsure please post your ini file.

The following user(s) said Thank You: TheTinkeringMechanic1

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21059

- Thank you received: 7183

07 Jun 2025 17:47 #329888

by tommylight

Replied by tommylight on topic CNC lathe to grinder.

I do not have much experience with lathe, but homing near the chuck is just asking for trouble, there is a damn good reason to home as far as possible from the chuck, especially if the machine has a toolchanger.

Please Log in or Create an account to join the conversation.

- TheTinkeringMechanic1

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 3

07 Jun 2025 18:44 #329891

by TheTinkeringMechanic1

Replied by TheTinkeringMechanic1 on topic CNC lathe to grinder.

I will get this posted as soon as I can. Thank you.

Please Log in or Create an account to join the conversation.

- TheTinkeringMechanic1

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 3

07 Jun 2025 18:46 #329892

by TheTinkeringMechanic1

Replied by TheTinkeringMechanic1 on topic CNC lathe to grinder.

Please read the post fully to understand why this is necessary.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21059

- Thank you received: 7183

07 Jun 2025 21:16 #329900

by tommylight

Replied by tommylight on topic CNC lathe to grinder.

I did, but i forgot, sorry.

Please Log in or Create an account to join the conversation.

- TheTinkeringMechanic1

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 3

08 Jun 2025 02:26 #329922

by TheTinkeringMechanic1

Replied by TheTinkeringMechanic1 on topic CNC lathe to grinder.

This should be it.

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4615

- Thank you received: 2042

08 Jun 2025 10:07 #329934

by Aciera

Replied by Aciera on topic CNC lathe to grinder.

You have set your limits to:

Try inverting your limits in [AXIS_Z] and [JOINT_1] sections:

MIN_LIMIT = -30.0

MAX_LIMIT = 0.25Try inverting your limits in [AXIS_Z] and [JOINT_1] sections:

MIN_LIMIT = -0.25

MAX_LIMIT = 30.0Please Log in or Create an account to join the conversation.

- TheTinkeringMechanic1

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 3

08 Jun 2025 11:39 #329939

by TheTinkeringMechanic1

Replied by TheTinkeringMechanic1 on topic CNC lathe to grinder.

I knew it had to be something simple I was overlooking. I'll give this a try. Thanks for the explanation.

Please Log in or Create an account to join the conversation.

- TheTinkeringMechanic1

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 3

08 Jun 2025 19:52 - 08 Jun 2025 19:55 #329968

by TheTinkeringMechanic1

Replied by TheTinkeringMechanic1 on topic CNC lathe to grinder.

Hmm. It appears it won't allow me to do that. LinuxCNC terminated with an error.

Attachments:

Last edit: 08 Jun 2025 19:55 by TheTinkeringMechanic1.

Please Log in or Create an account to join the conversation.

Time to create page: 0.144 seconds