RPi5 and 7C81, manual control is choppy

- AkkiSan

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

03 Aug 2025 14:49 - 03 Aug 2025 14:55 #332726

by AkkiSan

RPi5 and 7C81, manual control is choppy was created by AkkiSan

I had a couple of Mesa cards laying around for years and finally found some time to put it into operation.

Especially because the RPi5 comes with this massive performance boost <3

It’s all basically working, except for the pinout (had to solder an adapter), and everything seems to work in auto or MDI mode,

although I only tested a few moves; but manual control is extremely choppy.

The constant movement is just interrupted, as I would have stopped pushing the the button.

Acceleration/deceleration is working, so it’s not a communication issue.

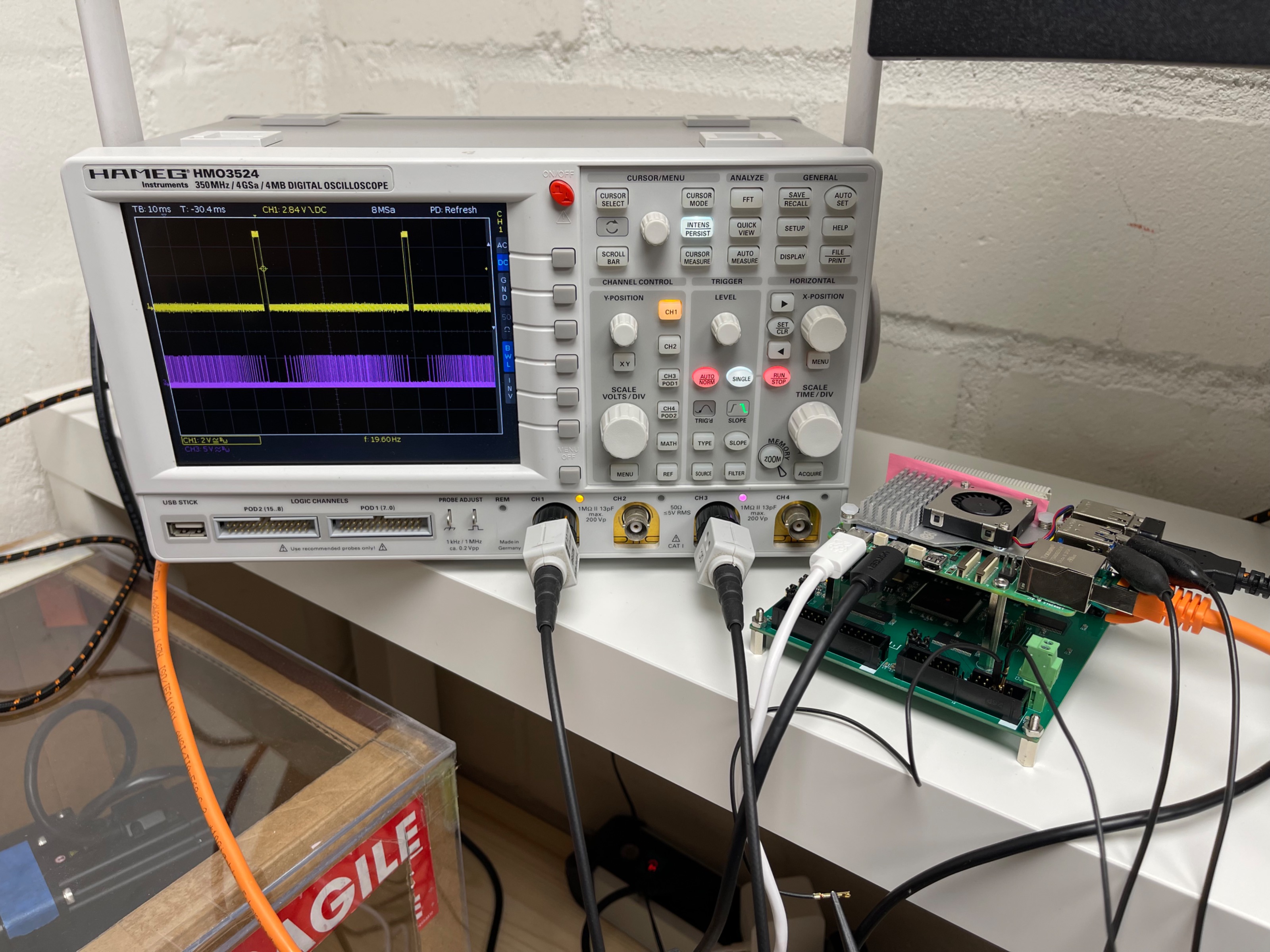

Here:

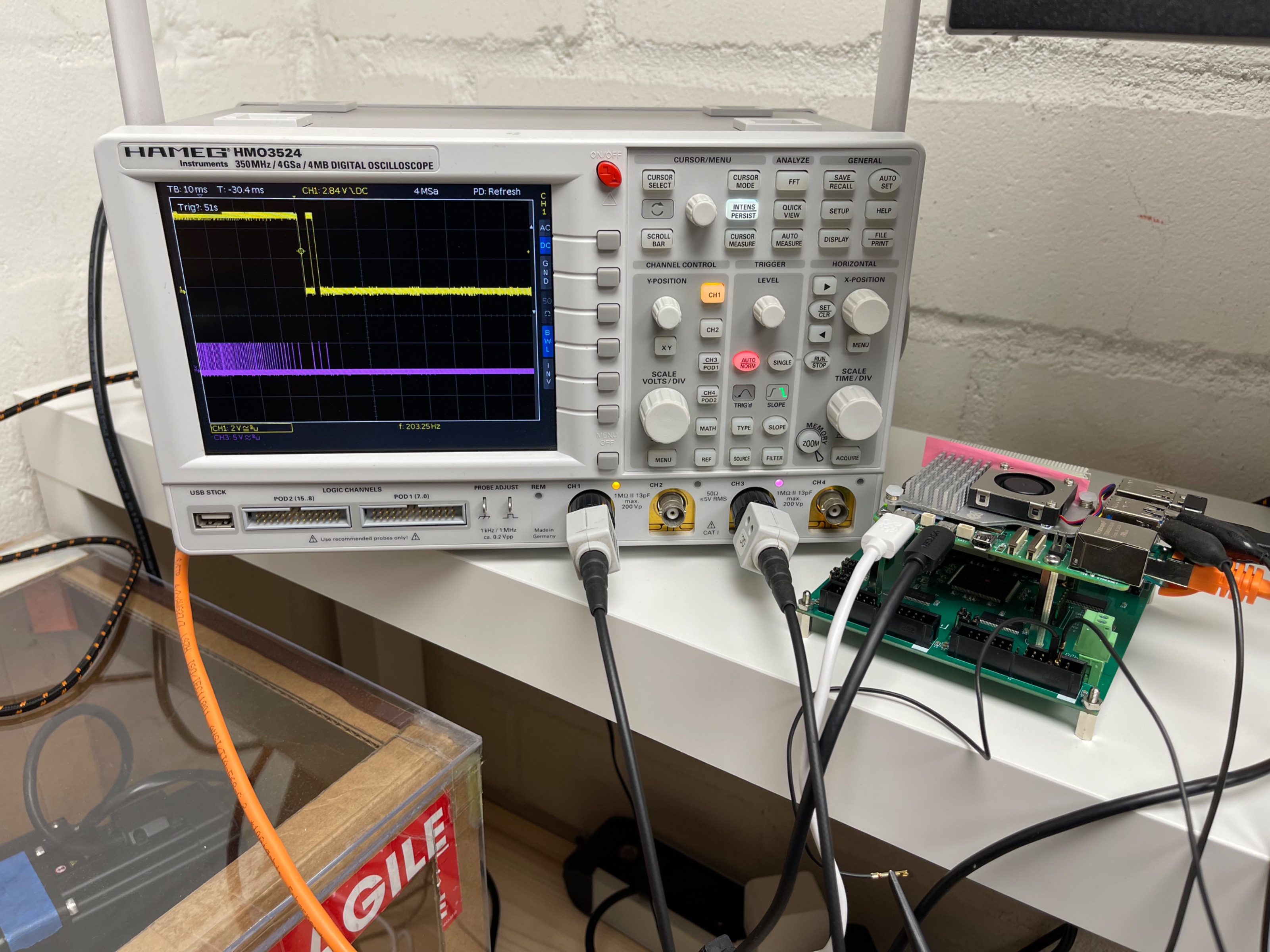

Probably unrelated, but strange:

At the end of rapid moves, controlled via MDI, the controller or LinuxCNC creates some extra steps.

I did not count them yet, but will check this after the rest is okay:

Are these “user space” issues? Currently I exclusively have older RTAI setups working;

never used this one kernel thingy.

Did I set up anything incorrectly?

thx

AS

Especially because the RPi5 comes with this massive performance boost <3

It’s all basically working, except for the pinout (had to solder an adapter), and everything seems to work in auto or MDI mode,

although I only tested a few moves; but manual control is extremely choppy.

The constant movement is just interrupted, as I would have stopped pushing the the button.

Acceleration/deceleration is working, so it’s not a communication issue.

Here:

Probably unrelated, but strange:

At the end of rapid moves, controlled via MDI, the controller or LinuxCNC creates some extra steps.

I did not count them yet, but will check this after the rest is okay:

Are these “user space” issues? Currently I exclusively have older RTAI setups working;

never used this one kernel thingy.

Did I set up anything incorrectly?

thx

AS

Attachments:

Last edit: 03 Aug 2025 14:55 by AkkiSan.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17747

- Thank you received: 5189

03 Aug 2025 16:14 - 03 Aug 2025 16:14 #332736

by PCW

Replied by PCW on topic RPi5 and 7C81, manual control is choppy

The jogging issue is probably the standard problem with KB repeat

The overshoot is likely a tuning issue, I would use the standard velocity mode/PID stepgen control

(use a pncconf created configuration for an example) Also make sure to use the DPLL for stepgen

configurations (use pncconf again as an example here)

The overshoot is likely a tuning issue, I would use the standard velocity mode/PID stepgen control

(use a pncconf created configuration for an example) Also make sure to use the DPLL for stepgen

configurations (use pncconf again as an example here)

Last edit: 03 Aug 2025 16:14 by PCW.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

03 Aug 2025 19:20 #332747

by tommylight

Replied by tommylight on topic RPi5 and 7C81, manual control is choppy

Keyboard jogging issue

www.forum.linuxcnc.org/38-general-linuxc...elocity-fluctuations

www.forum.linuxcnc.org/38-general-linuxc...elocity-fluctuations

Please Log in or Create an account to join the conversation.

- AkkiSan

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

04 Aug 2025 17:37 #332831

by AkkiSan

Maybe I should borrow $CHILD2's gaming keyboard and set the polling rate

to 20kHz. I bet that the movement then cannot be stopped in time, hehe.

The units all seem to have changed from 2.8 to 2.9. Instead of periods/time we now have rates/frequency.

I have 20+ years experience with running everything through the parallel port but 0 with Mesa cards.

I also noticed that the former "BASE_PERIOD" (forgot what the name is now and I currently do not have

access to the new config; forgot them in the workshop) is not in the ini-file anymore.

Not sure if this value can be changed at all. The Mesa docs are more than sparse, imho.

I must admit that I don't know exactly understand what you mean.

Is there also an "extraordinary velocity mode"? And what is DPLL?

thx

AS

Replied by AkkiSan on topic RPi5 and 7C81, manual control is choppy

Grundgütiger. Lol; thx!Keyboard jogging issue

www.forum.linuxcnc.org/38-general-linuxc...elocity-fluctuations

Maybe I should borrow $CHILD2's gaming keyboard and set the polling rate

to 20kHz. I bet that the movement then cannot be stopped in time, hehe.

I created the config file with pncconf and left thePCW post=332736 userid=481[...]

The overshoot is likely a tuning issue, I would use the standard velocity mode/PID stepgen control

(use a pncconf created configuration for an example) Also make sure to use the DPLL for stepgen

configurations (use pncconf again as an example here)

The units all seem to have changed from 2.8 to 2.9. Instead of periods/time we now have rates/frequency.

I have 20+ years experience with running everything through the parallel port but 0 with Mesa cards.

I also noticed that the former "BASE_PERIOD" (forgot what the name is now and I currently do not have

access to the new config; forgot them in the workshop) is not in the ini-file anymore.

Not sure if this value can be changed at all. The Mesa docs are more than sparse, imho.

I must admit that I don't know exactly understand what you mean.

Is there also an "extraordinary velocity mode"? And what is DPLL?

thx

AS

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17747

- Thank you received: 5189

04 Aug 2025 17:51 - 04 Aug 2025 17:51 #332833

by PCW

Replied by PCW on topic RPi5 and 7C81, manual control is choppy

There have been no motion unit changes AFAIK between 2.8 and 2.9

A base period is not needed with hardware stepgens/encoder counters

(nor is it very useful with SPI or Ethernet connections)

The DPLL is a Digital Phase Locked Loop that re-times critical sampling times

(like sampling the current hardware stepgen position) This can reduce

the sample time uncertainty from 100s of usec to 100s of ns

Typical setup for Mesa stepgens is like:

# latch 100 usec before nominal read time:

setp hm2_[HOSTMOT2](BOARD).0.dpll.01.timer-us -100

setp hm2_[HOSTMOT2](BOARD).0.stepgen.timer-number 1

A base period is not needed with hardware stepgens/encoder counters

(nor is it very useful with SPI or Ethernet connections)

The DPLL is a Digital Phase Locked Loop that re-times critical sampling times

(like sampling the current hardware stepgen position) This can reduce

the sample time uncertainty from 100s of usec to 100s of ns

Typical setup for Mesa stepgens is like:

# latch 100 usec before nominal read time:

setp hm2_[HOSTMOT2](BOARD).0.dpll.01.timer-us -100

setp hm2_[HOSTMOT2](BOARD).0.stepgen.timer-number 1

Last edit: 04 Aug 2025 17:51 by PCW.

Please Log in or Create an account to join the conversation.

- AkkiSan

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 2

04 Aug 2025 18:13 #332835

by AkkiSan

Replied by AkkiSan on topic RPi5 and 7C81, manual control is choppy

Thank you very much.

I will test this.

As far as I remember, there also were PID settings, either in

the pncconfig GUI or the config file itself.

Only P was set, which seems odd.

Are these settings even valid or doing something in

an encoderless setup?

thx

AS

I will test this.

As far as I remember, there also were PID settings, either in

the pncconfig GUI or the config file itself.

Only P was set, which seems odd.

Are these settings even valid or doing something in

an encoderless setup?

thx

AS

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17747

- Thank you received: 5189

04 Aug 2025 19:16 - 05 Aug 2025 14:10 #332839

by PCW

Replied by PCW on topic RPi5 and 7C81, manual control is choppy

For the PID settings for a hardware stepgen, P should normally be

1/Servo-thread-period so 1000 for a 1 ms servo thread period,

and FF1 should be 1.000.

The physical meaning of these setting is this:

P=1/Servo-thread-period means correct any detected position

error by the next servo thread invocation.

FF1= 1.000 means set the base stepgen velocity to LinuxCNCs commanded

velocity (to center the operating point of the PID loop on the current velocity)

This means the P term has little to do besides correcting for minor time base

differences between LinuxCNC and the hardware.

1/Servo-thread-period so 1000 for a 1 ms servo thread period,

and FF1 should be 1.000.

The physical meaning of these setting is this:

P=1/Servo-thread-period means correct any detected position

error by the next servo thread invocation.

FF1= 1.000 means set the base stepgen velocity to LinuxCNCs commanded

velocity (to center the operating point of the PID loop on the current velocity)

This means the P term has little to do besides correcting for minor time base

differences between LinuxCNC and the hardware.

Last edit: 05 Aug 2025 14:10 by PCW.

Please Log in or Create an account to join the conversation.

Time to create page: 0.139 seconds