Linuxcnc Press brake - Open Source

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11719

- Thank you received: 3967

He meant for parts use 16mm.

Bending 16mm is another level where only a few dare to wander.

I have seen it done. My mate Buddy has one part from 16mm that requires a tight radius that can't be done so he slots the part when its laser cut, then backfills it with weld after folding (which leaves a nice V slot). That gives him full penetration of the weld for maximum strength. A competitor does it in two pieces with the parts offset so there is a fillet weld each side but its not as strong (less penetration) and has been known to break..

Clive,I think it would be asking a bit much to make a bake out of 12 mm but with tab and slot bracing maybe it can be done. There is DIY a design kicking around (on pirate4x4 I think) that has a single hydraulic ram and a lever/cam design to drop the top punch. A few also make make laminated V tooling for the lower die with a plasma cutter.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11719

- Thank you received: 3967

Attachments:

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

- Visitor

-

I would stay at 1M wide in respect to us in the oldest continent.

That maybe so but we have world's largest single rock monolith and largest population of feral camels.

Oh yeah we also had a war with emus....and lost

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11719

- Thank you received: 3967

Oh yeah we also had a war with emus....and lost

This is true. I still remember scratching for gears in an old motorbike with old man emu snapping at my ass. I swear that long neck looked like a rifle barrel! All becasue I got a bit too close to his nest filled with her chicks, But heck I laughed the next day after I discretely ensured my brother followed the same line I had. Old man Emu was more than pissed by then. I thought he nearly had my bro!

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Clive,I think it would be asking a bit much to make a bake out of 12 mm but with tab and slot bracing maybe it can be done. There is DIY a design kicking around (on pirate4x4 I think) that has a single hydraulic ram and a lever/cam design to drop the top punch. A few also make make laminated V tooling for the lower die with a plasma cutter.

I agree. I was thinking that you wanted it to bend 16mm.

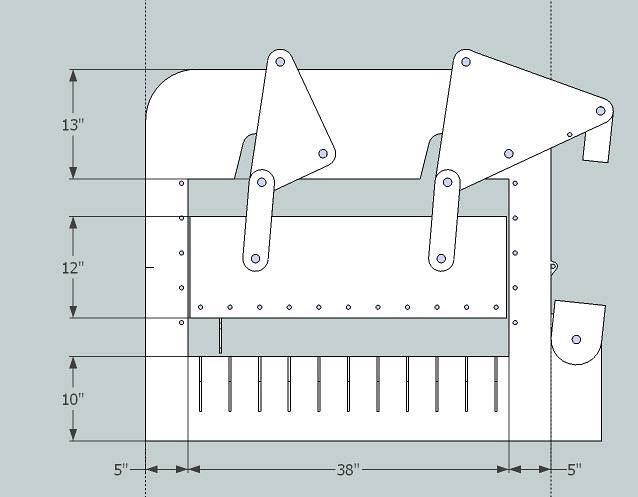

This is one my mate is building all cut out with PlasmaC

I think it is 100 box with 10mm wall

Attachments:

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 196

- Thank you received: 128

ram has linear encoder ?

or endstops move up and down?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

[2]

ram has linear encoder ?

or endstops move up and down?

This is a work in progress. I am sure it could be cnc'd

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

m5c

Mike

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Sorry, but if you do not have the material precisely in the middle it will not press square. With three cylinders parallel connected this constrution will move that cylinder the longest way witch has the lessest force to fight.

m5c

Mike

Yes I had thought that as well. How do the presses work with a ram at each side as that would have the same problem.

I don't have any experience with this sort of stuff.

Please Log in or Create an account to join the conversation.