Linuxcnc Press brake - Open Source

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7231

10 Oct 2020 21:29 #185637

by tommylight

Replied by tommylight on topic Linuxcnc Press brake - Open Source

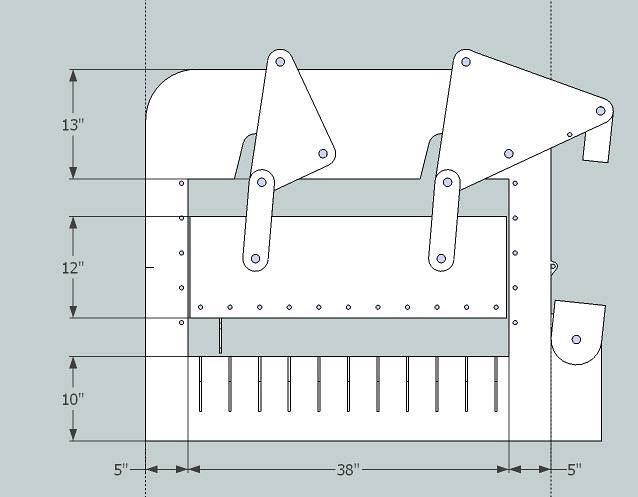

More of this, please.Here you go

Not Shown: Ram on the right plus an adjustable tractor drawbar linkage across the top

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7231

10 Oct 2020 21:33 #185639

by tommylight

Here you can run have a run in with a bear and the bear will be scared shitless from nearly 10 years of trauma gathered from people shooting them on sight. Luckily that has stopped so lately they are growing in numbers.

Replied by tommylight on topic Linuxcnc Press brake - Open Source

LOL @ emus !

Oh yeah we also had a war with emus....and lost

This is true. I still remember scratching for gears in an old motorbike with old man emu snapping at my ass. I swear that long neck looked like a rifle barrel! All becasue I got a bit too close to his nest filled with her chicks, But heck I laughed the next day after I discretely ensured my brother followed the same line I had. Old man Emu was more than pissed by then. I thought he nearly had my bro!

Here you can run have a run in with a bear and the bear will be scared shitless from nearly 10 years of trauma gathered from people shooting them on sight. Luckily that has stopped so lately they are growing in numbers.

The following user(s) said Thank You: pinder

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11625

- Thank you received: 3913

11 Oct 2020 04:15 #185663

by rodw

Replied by rodw on topic Linuxcnc Press brake - Open Source

Here you can run have a run in with a bear and the bear will be scared shitless from nearly 10 years of trauma gathered from people shooting them on sight. Luckily that has stopped so lately they are growing in numbers.

I think I'd be scared shitless and traumatised enough to shoot on sight too!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11625

- Thank you received: 3913

11 Oct 2020 04:43 #185664

by rodw

Here www.plasmaspider.com/viewtopic.php?t=16771

which takes you to some pics here

www.pirate4x4.com/threads/press-brake-bu...ed-auto-tna.1725178/

Replied by rodw on topic Linuxcnc Press brake - Open Source

More of this, please.

Here www.plasmaspider.com/viewtopic.php?t=16771

which takes you to some pics here

www.pirate4x4.com/threads/press-brake-bu...ed-auto-tna.1725178/

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

11 Oct 2020 06:11 - 11 Oct 2020 06:13 #185667

by pinder

Replied by pinder on topic Linuxcnc Press brake - Open Source

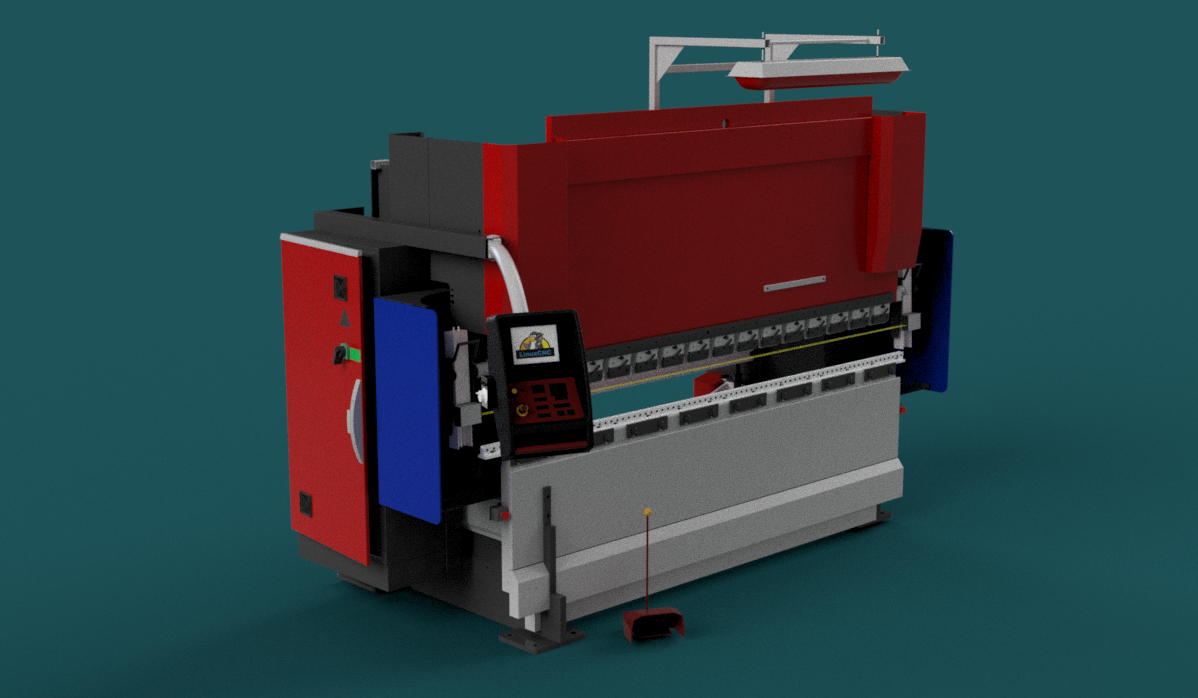

deep digging some non-english forums and websites led me to a nice Cad model.

I think it's an Amada press brake. I will update with links for files.

What format suits you all. F3d or stp?

people with cad abilities can modify and update it.

I think it's an Amada press brake. I will update with links for files.

What format suits you all. F3d or stp?

people with cad abilities can modify and update it.

Last edit: 11 Oct 2020 06:13 by pinder.

The following user(s) said Thank You: rodw, anfänger

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11625

- Thank you received: 3913

11 Oct 2020 07:10 #185672

by rodw

Replied by rodw on topic Linuxcnc Press brake - Open Source

The following user(s) said Thank You: pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

11 Oct 2020 07:58 #185675

by pinder

Replied by pinder on topic Linuxcnc Press brake - Open Source

I made some translations.

You can check github for source and edit.

github.com/hardwork-machines/Linuxcnc-Press-Brake

You can check github for source and edit.

github.com/hardwork-machines/Linuxcnc-Press-Brake

Attachments:

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

27 Oct 2020 17:56 - 27 Oct 2020 17:58 #187447

by pinder

Replied by pinder on topic Linuxcnc Press brake - Open Source

A question. Am I right here?

I think there there are two option for setting the tool height

1) we use linear encoders along with ram.

2) we can use ballscrews on both sides which trigger endstops. When we need different height l, setter moves up or down.

Foot pedal triggers the ram down until it hits endstop and then returns up.

I think there there are two option for setting the tool height

1) we use linear encoders along with ram.

2) we can use ballscrews on both sides which trigger endstops. When we need different height l, setter moves up or down.

Foot pedal triggers the ram down until it hits endstop and then returns up.

Last edit: 27 Oct 2020 17:58 by pinder.

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

27 Oct 2020 20:25 #187464

by aleksamc

Replied by aleksamc on topic Linuxcnc Press brake - Open Source

I think that for getting height you need to take linear encoder. If there is source of presure from few sourses, then you need linear encoders on two sides of press. Presure in each cylinder should be controled separetly.

Bottom side of press form should be one height. Up side of press form could be changable. It's height should be controlled with laser pointer with mirror that will give height of that pressform.

If press need to control only angle, than PLC is enough. You need to know only thikness of the material and bending radius.

It's m vision for this.

Bottom side of press form should be one height. Up side of press form could be changable. It's height should be controlled with laser pointer with mirror that will give height of that pressform.

If press need to control only angle, than PLC is enough. You need to know only thikness of the material and bending radius.

It's m vision for this.

The following user(s) said Thank You: Diederik, pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

28 Oct 2020 04:35 #187496

by pinder

Replied by pinder on topic Linuxcnc Press brake - Open Source

Thankyou for your suggestions @aleksamc

Controlling pressure separately is nice idea.

Can you some some examples of mirror and laser thing?

Cheers,

Pinder

Controlling pressure separately is nice idea.

Can you some some examples of mirror and laser thing?

Cheers,

Pinder

Please Log in or Create an account to join the conversation.

Time to create page: 0.143 seconds