New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

- KoenigCNC

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

06 Mar 2019 17:42 #127903

by KoenigCNC

Replied by KoenigCNC on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

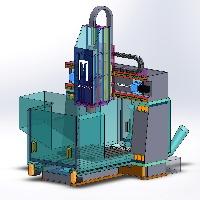

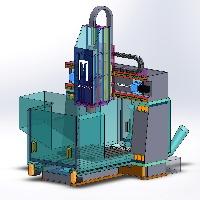

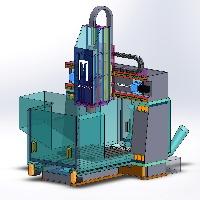

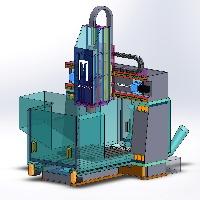

Hi Tommy. For a complete Frame, Base Risers, Bridge Z axis, completely machined, stress relieved drilled and tapped ready mount ball-screws and linear rails along with drawings required for assembly around $20,000 I will make available the ballscrews, tool changers, Linear guides, spindle, enclosure, chip augers and all the other parts. I will also make available drawing for the parts in case someone can acquire the parts for less than I can get them for. Ball-screws I use are Ground, Linear rails are 45mm Precision. It intended to be an industrial quality machine comparable to other VMC in the marketplace.

Once of the biggest challenges to building a machine like this is building and machining the frame sourcing the parts and doing it at a reasonable price. I would it to cost about 40% less than a comparable machine sold. The savings is in using the Linuxcnc control and assembling the parts by the end user. Much like building a Kit Airplane.

I have a source for Yaskawa, Delta and other Servos and Drives.

First 3 frames will be ready ion about 30 days. I am making test cuts today on my gantry. Just did a 24 hour run off with no alarms. Today I am doing a 24 Hour test cut program.

I still have a lot of loose ends to tie up but its looking good

Once of the biggest challenges to building a machine like this is building and machining the frame sourcing the parts and doing it at a reasonable price. I would it to cost about 40% less than a comparable machine sold. The savings is in using the Linuxcnc control and assembling the parts by the end user. Much like building a Kit Airplane.

I have a source for Yaskawa, Delta and other Servos and Drives.

First 3 frames will be ready ion about 30 days. I am making test cuts today on my gantry. Just did a 24 hour run off with no alarms. Today I am doing a 24 Hour test cut program.

I still have a lot of loose ends to tie up but its looking good

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

07 Mar 2019 12:56 #127968

by pl7i92

Replied by pl7i92 on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

i got some problem with theis Gantry setup you choosen

as there are all rotation axis in the Z

this loses alot of space and need bigger mashine

insted using a XC setup and a Z,BAxis at the Gantry moving on Y railing

this gives the full space and only ads the toollength to the Rotation Table Diameter

Best to go for

as there are all rotation axis in the Z

this loses alot of space and need bigger mashine

insted using a XC setup and a Z,BAxis at the Gantry moving on Y railing

this gives the full space and only ads the toollength to the Rotation Table Diameter

Best to go for

Please Log in or Create an account to join the conversation.

- KoenigCNC

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

07 Mar 2019 16:31 #127997

by KoenigCNC

Replied by KoenigCNC on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

Hi, Which machine? My new mill is a Bridge Mill not a Gantry. It has 40 x 40 x 30 inches of travel. My Big Gantry has 150 x 72 x 60 with 6 Feet under the Bridge With the new mill the Y axis is the Table and the x and z or on the Bridge. I one or two axis rotary table could be fitted on the table to allow 4 or 5 axis machine work. I have several other small machine designs I am working on also Small bridge type machine. Getting more Y axis travel in a small footprint is the goal.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

07 Mar 2019 16:38 #127999

by pl7i92

Replied by pl7i92 on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

Ich meinte diese Hier

forum.linuxcnc.org/54-user-exchange/3283...ject?start=10#126720

der Kopf soll ja um das werkstück da ist nicht viel platz bei einem 300mm langen Fräser

bei einem Dehtisch wäre in der Längsrichtung massig platz

forum.linuxcnc.org/54-user-exchange/3283...ject?start=10#126720

der Kopf soll ja um das werkstück da ist nicht viel platz bei einem 300mm langen Fräser

bei einem Dehtisch wäre in der Längsrichtung massig platz

Please Log in or Create an account to join the conversation.

- KoenigCNC

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

07 Mar 2019 16:56 #128003

by KoenigCNC

Replied by KoenigCNC on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

That was the last Gantry I built it was designed to be a five axis to make tooling for large molded parts it needed to get around all sides of the tool. The new gantry pictured is a 3 axis built for the sole purpose of machine all the parts for my new smaller machine it just 3 axis but it will have 50 Plus inches of travel in the z to be able to machine the riser of the new machine.It does have 72 inches under the Bridge. On this machine the Gantry(bridge) moves and my new small machine the Table moves in the Y axis.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

08 Mar 2019 11:28 #128075

by pl7i92

Replied by pl7i92 on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

amazing

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

08 Mar 2019 13:14 - 08 Mar 2019 13:15 #128078

by andypugh

Replied by andypugh on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

For your next machine, maybe something like this (attached PDF file)

"It features an X-axis travel

of 12m, a W-axis travel (vertical movement of

the cross-beam carried by the two columns) of

2.5m, a Y-axis travel (spindle movement along

the cross-beam) of 7.5m, and a ram stroke (Zaxis) of 1.5m. Moreover, with its German-built

Cytec head, this machine offers a full five-axis

simultaneous-machining capability. "

"It features an X-axis travel

of 12m, a W-axis travel (vertical movement of

the cross-beam carried by the two columns) of

2.5m, a Y-axis travel (spindle movement along

the cross-beam) of 7.5m, and a ram stroke (Zaxis) of 1.5m. Moreover, with its German-built

Cytec head, this machine offers a full five-axis

simultaneous-machining capability. "

Last edit: 08 Mar 2019 13:15 by andypugh.

Please Log in or Create an account to join the conversation.

- KoenigCNC

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

08 Mar 2019 15:52 #128086

by KoenigCNC

Replied by KoenigCNC on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

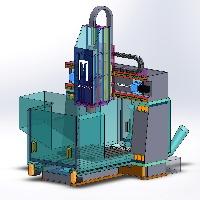

Attachments:

Please Log in or Create an account to join the conversation.

- KoenigCNC

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

08 Mar 2019 15:58 - 08 Mar 2019 15:58 #128087

by KoenigCNC

Replied by KoenigCNC on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

Attachments:

Last edit: 08 Mar 2019 15:58 by KoenigCNC. Reason: Typo

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7246

08 Mar 2019 22:52 #128114

by tommylight

Replied by tommylight on topic New CNC Mill, Expert LinuxCNC person wanted for new VMC Project.

Like a kid in a candy shop !

Nice and big and........

Nice and big and........

Please Log in or Create an account to join the conversation.

Time to create page: 0.408 seconds