Search Results (Searched for: 7i76e)

- nichtAlex

- nichtAlex

12 Aug 2025 19:16

Replied by nichtAlex on topic Mesa 7i76eu gpio pins not working

Mesa 7i76eu gpio pins not working

Category: General LinuxCNC Questions

- jimmyrig

- jimmyrig

12 Aug 2025 07:46 - 12 Aug 2025 07:47

Replied by jimmyrig on topic Mesa 7i76eu gpio pins not working

Mesa 7i76eu gpio pins not working

Category: General LinuxCNC Questions

- LeonDolnicar

- LeonDolnicar

12 Aug 2025 07:41

Mesa 7i76eu gpio pins not working was created by LeonDolnicar

Mesa 7i76eu gpio pins not working

Category: General LinuxCNC Questions

- SebastianM

- SebastianM

07 Aug 2025 20:25

Replied by SebastianM on topic "KeyError" suddenly appears after moving a limitswitch

"KeyError" suddenly appears after moving a limitswitch

Category: QtPyVCP

- PCW

07 Aug 2025 03:27

Replied by PCW on topic Using a 7i95T for 3 axis + handwheels

Using a 7i95T for 3 axis + handwheels

Category: Advanced Configuration

- MikkelRS

07 Aug 2025 03:09

Replied by MikkelRS on topic Using a 7i95T for 3 axis + handwheels

Using a 7i95T for 3 axis + handwheels

Category: Advanced Configuration

- SebastianM

- SebastianM

06 Aug 2025 19:11 - 06 Aug 2025 22:01

Replied by SebastianM on topic "KeyError" suddenly appears after moving a limitswitch

"KeyError" suddenly appears after moving a limitswitch

Category: QtPyVCP

- tsaG

- tsaG

06 Aug 2025 09:49

Replied by tsaG on topic Enable / Disable Output when Spindle is ON /OFF

Enable / Disable Output when Spindle is ON /OFF

Category: Advanced Configuration

- tommylight

05 Aug 2025 22:09

Replied by tommylight on topic Enable / Disable Output when Spindle is ON /OFF

Enable / Disable Output when Spindle is ON /OFF

Category: Advanced Configuration

- tsaG

- tsaG

05 Aug 2025 21:53

Replied by tsaG on topic Enable / Disable Output when Spindle is ON /OFF

Enable / Disable Output when Spindle is ON /OFF

Category: Advanced Configuration

- Daroum

- Daroum

04 Aug 2025 09:13

- Benb

03 Aug 2025 21:33

Replied by Benb on topic Switch relay in a defined x position

Switch relay in a defined x position

Category: Advanced Configuration

- pkludwig

03 Aug 2025 10:12

Replied by pkludwig on topic Simulating a hm2_eth driver (e.g. mesacard 7i76e)

Simulating a hm2_eth driver (e.g. mesacard 7i76e)

Category: Driver Boards

- zzrzzr

- zzrzzr

02 Aug 2025 14:45 - 02 Aug 2025 14:46

- tcbmetalworks

- tcbmetalworks

27 Jul 2025 21:51

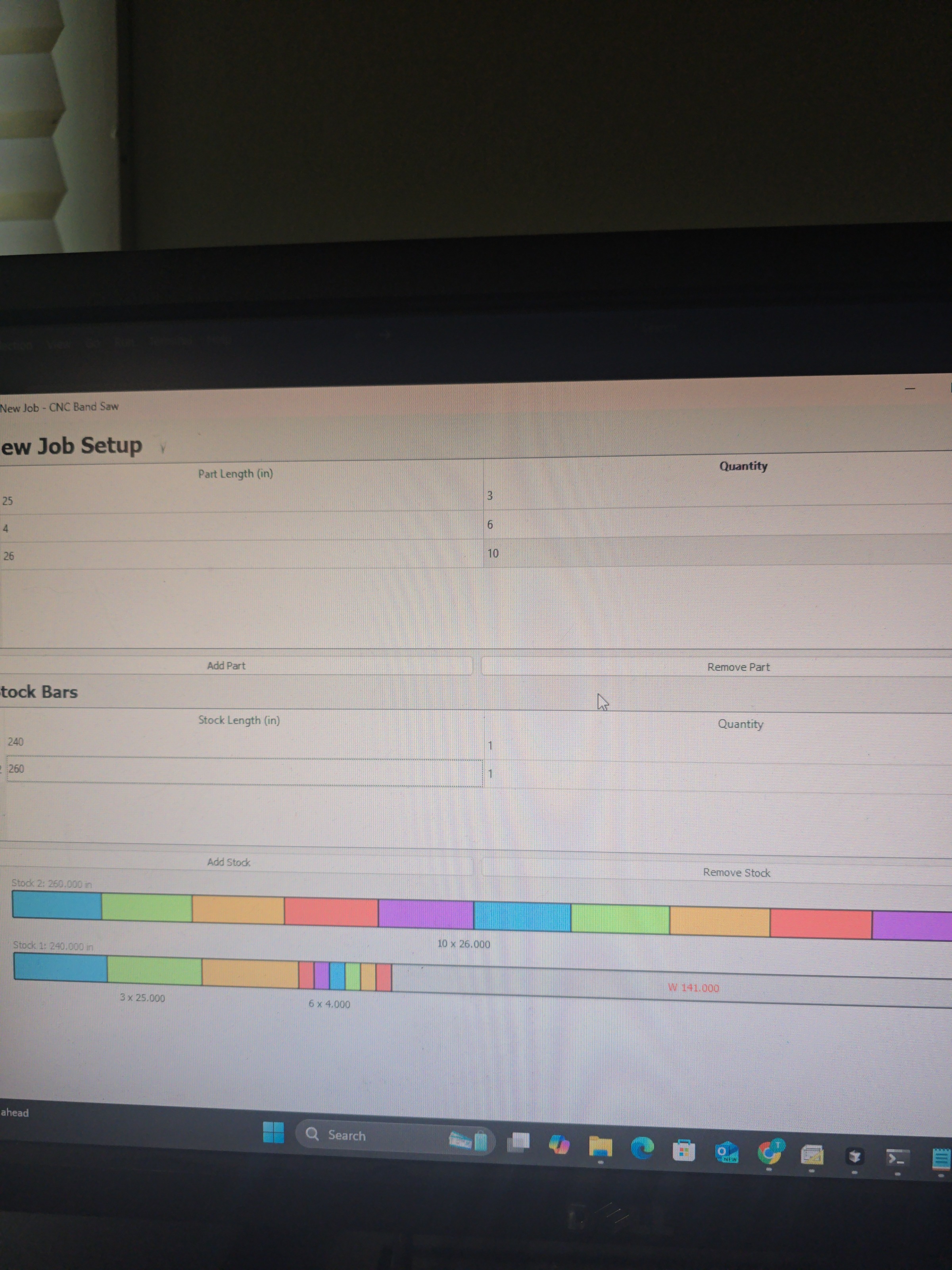

Replied by tcbmetalworks on topic Automatic band saw marvel v10a

Automatic band saw marvel v10a

Category: CNC Machines

Time to create page: 9.337 seconds