Search Results (Searched for: XHC)

- Finngineering

- Finngineering

02 Mar 2026 11:27

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Aciera

02 Mar 2026 06:49

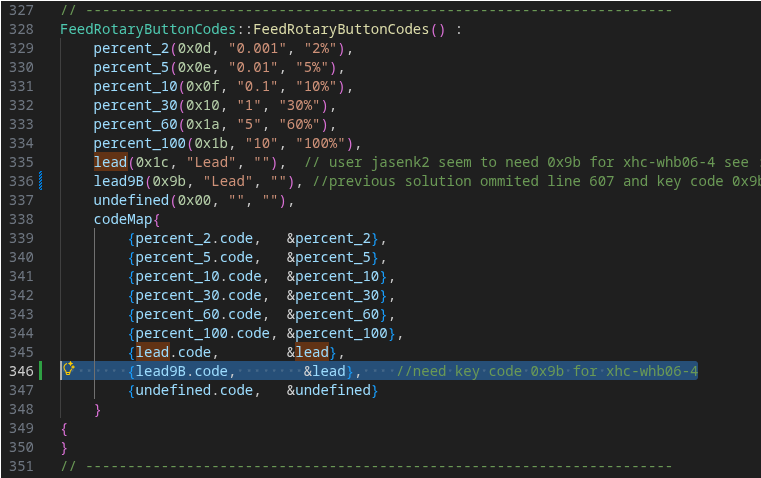

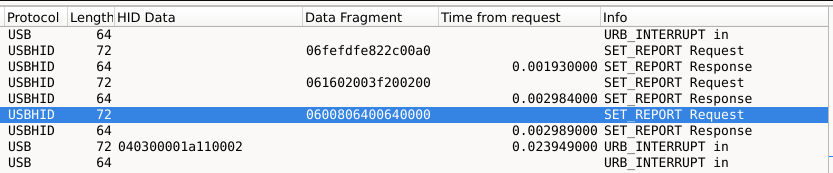

Replied by Aciera on topic Handrad XHC-WHB04b-6 braucht 9b für LEAD Funktion

Handrad XHC-WHB04b-6 braucht 9b für LEAD Funktion

Category: Deutsch

- Q-Man0815

- Q-Man0815

01 Mar 2026 16:29 - 02 Mar 2026 06:37

Handrad XHC-WHB04b-6 braucht 9b für LEAD Funktion was created by Q-Man0815

Handrad XHC-WHB04b-6 braucht 9b für LEAD Funktion

Category: Deutsch

- Finngineering

- Finngineering

01 Mar 2026 14:05

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hakan

- Hakan

01 Mar 2026 11:31 - 01 Mar 2026 11:33

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Finngineering

- Finngineering

01 Mar 2026 06:51

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hakan

- Hakan

28 Feb 2026 20:20

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Finngineering

- Finngineering

28 Feb 2026 17:28

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Finngineering

- Finngineering

28 Feb 2026 13:11

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hannes

- Hannes

28 Feb 2026 10:40

Replied by Hannes on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hakan

- Hakan

28 Feb 2026 09:18

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Finngineering

- Finngineering

28 Feb 2026 07:08

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Finngineering

- Finngineering

27 Feb 2026 07:24

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hannes

- Hannes

26 Feb 2026 22:01 - 26 Feb 2026 22:02

Replied by Hannes on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hannes

- Hannes

26 Feb 2026 21:07

Replied by Hannes on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

Time to create page: 0.434 seconds