Search Results (Searched for: )

- ffffrf

- ffffrf

05 Nov 2025 02:58

Replied by ffffrf on topic Probe basic error exceeding axis negative value during calibration

Probe basic error exceeding axis negative value during calibration

Category: QtPyVCP

- ffffrf

- ffffrf

05 Nov 2025 02:40

Replied by ffffrf on topic Probe basic error exceeding axis negative value during calibration

Probe basic error exceeding axis negative value during calibration

Category: QtPyVCP

- ffffrf

- ffffrf

05 Nov 2025 01:54 - 05 Nov 2025 02:08

- Jamanji

- Jamanji

05 Nov 2025 01:13

Replied by Jamanji on topic issues with MESA to SCARA kins

issues with MESA to SCARA kins

Category: Basic Configuration

- Quail

05 Nov 2025 00:31

Replied by Quail on topic QTPlasmaC Remove Z axis for Tube Cutter

QTPlasmaC Remove Z axis for Tube Cutter

Category: Plasma & Laser

- tommylight

05 Nov 2025 00:22

Replied by tommylight on topic QTPlasmaC Remove Z axis for Tube Cutter

QTPlasmaC Remove Z axis for Tube Cutter

Category: Plasma & Laser

- Quail

04 Nov 2025 23:42

Replied by Quail on topic QTPlasmaC Remove Z axis for Tube Cutter

QTPlasmaC Remove Z axis for Tube Cutter

Category: Plasma & Laser

- tommylight

04 Nov 2025 23:11

Replied by tommylight on topic CNC plasma tube cutter

CNC plasma tube cutter

Category: Show Your Stuff

- tommylight

04 Nov 2025 22:58

Replied by tommylight on topic Analog controller for servos

Analog controller for servos

Category: Driver Boards

- tommylight

04 Nov 2025 22:57

Replied by tommylight on topic Maho 700C A-axis (rotating table)

Maho 700C A-axis (rotating table)

Category: General LinuxCNC Questions

- tommylight

04 Nov 2025 22:53

Replied by tommylight on topic Suggest RTAI version for me

Suggest RTAI version for me

Category: General LinuxCNC Questions

- tommylight

04 Nov 2025 22:49

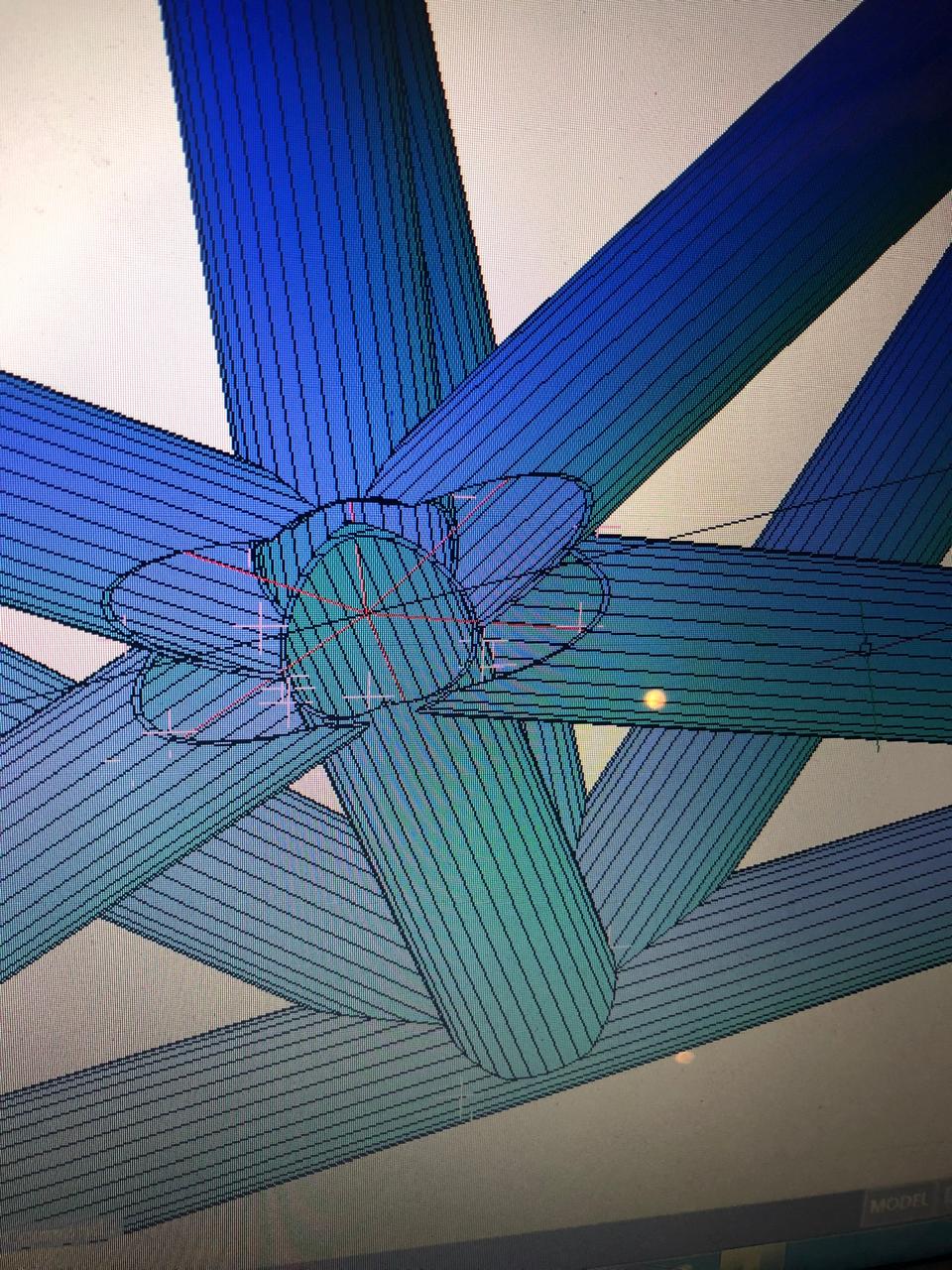

Replied by tommylight on topic CNC plasma tube cutter

CNC plasma tube cutter

Category: Show Your Stuff

- tommylight

04 Nov 2025 22:48

Replied by tommylight on topic CNC plasma tube cutter

CNC plasma tube cutter

Category: Show Your Stuff

- tommylight

04 Nov 2025 22:40

Replied by tommylight on topic QTPlasmaC Remove Z axis for Tube Cutter

QTPlasmaC Remove Z axis for Tube Cutter

Category: Plasma & Laser

- pgf

- pgf

04 Nov 2025 22:18

Time to create page: 0.377 seconds