Search Results (Searched for: )

- rodw

12 Dec 2024 17:45

Replied by rodw on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Mitch66

- Mitch66

12 Dec 2024 17:36

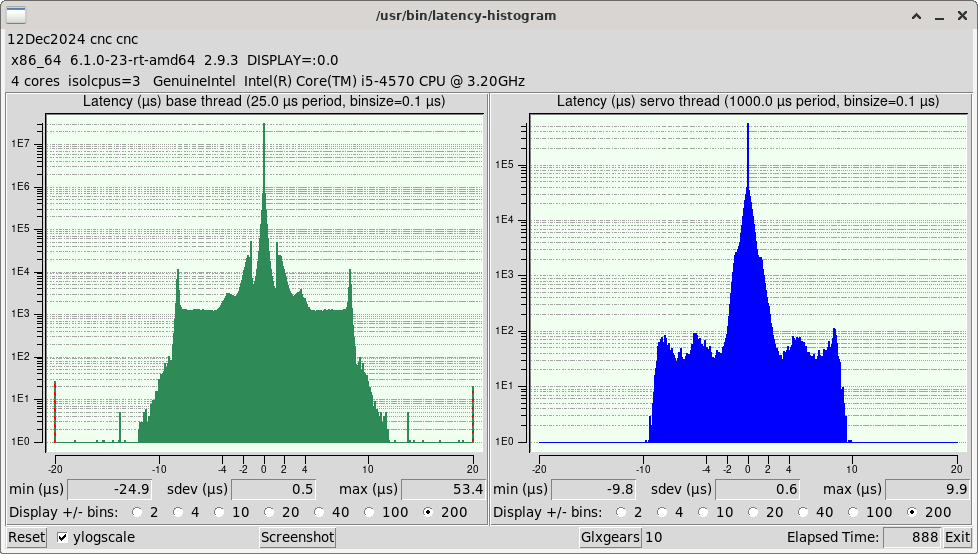

Replied by Mitch66 on topic Improving Base Thread Jitter

Improving Base Thread Jitter

Category: Installing LinuxCNC

- elovalvo

- elovalvo

12 Dec 2024 17:22

Replied by elovalvo on topic Newbie looking for a hardware configuration based on Raspberry Pi

Newbie looking for a hardware configuration based on Raspberry Pi

Category: Computers and Hardware

- PCW

12 Dec 2024 17:00

Replied by PCW on topic Improving Base Thread Jitter

Improving Base Thread Jitter

Category: Installing LinuxCNC

- PCW

12 Dec 2024 16:36

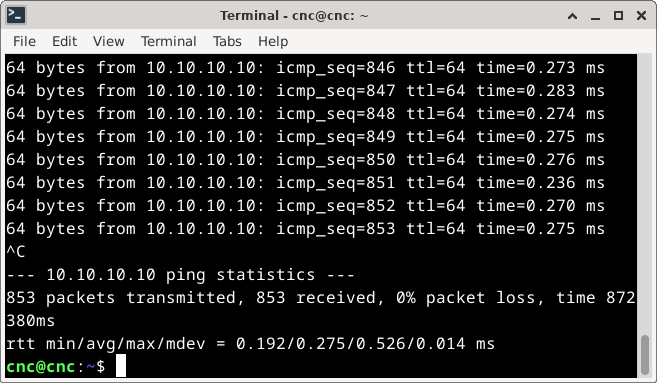

Replied by PCW on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- meister

- meister

12 Dec 2024 16:00

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- greg23_78

- greg23_78

12 Dec 2024 15:40 - 12 Dec 2024 16:02

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- ihavenofish

- ihavenofish

12 Dec 2024 15:39

Replied by ihavenofish on topic Rotating coordinate space via probing

Rotating coordinate space via probing

Category: General LinuxCNC Questions

- Mecanix

- Mecanix

12 Dec 2024 15:36

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Aciera

12 Dec 2024 15:32

- Mecanix

- Mecanix

12 Dec 2024 15:20 - 12 Dec 2024 15:21

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- PCW

12 Dec 2024 15:15

Replied by PCW on topic Changing stepgen position-scale parameter dynamically

Changing stepgen position-scale parameter dynamically

Category: Basic Configuration

- Mitch66

- Mitch66

12 Dec 2024 15:11

Improving Base Thread Jitter was created by Mitch66

Improving Base Thread Jitter

Category: Installing LinuxCNC

- Aciera

12 Dec 2024 15:07 - 12 Dec 2024 15:15

- CNC_ANDI

- CNC_ANDI

12 Dec 2024 14:54

Time to create page: 0.497 seconds