Search Results (Searched for: )

- PCW

06 May 2025 03:09

Replied by PCW on topic Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- unknown

- unknown

06 May 2025 03:06

Replied by unknown on topic ISO: Mesa to router interface board

ISO: Mesa to router interface board

Category: Driver Boards

- koch777

- koch777

06 May 2025 03:05 - 06 May 2025 03:07

Replied by koch777 on topic Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- tommylight

06 May 2025 02:56

Replied by tommylight on topic Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- koch777

- koch777

06 May 2025 02:43 - 06 May 2025 02:45

Replied by koch777 on topic Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- tommylight

06 May 2025 02:31

Replied by tommylight on topic Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- koch777

- koch777

06 May 2025 02:18

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2) was created by koch777

Troubles with Mesa 7I76EU + 7I76U(P1) + 7I89(P2)

Category: Driver Boards

- tommylight

06 May 2025 01:27

Replied by tommylight on topic ISO: Mesa to router interface board

ISO: Mesa to router interface board

Category: Driver Boards

- cakeslob

- cakeslob

06 May 2025 01:27

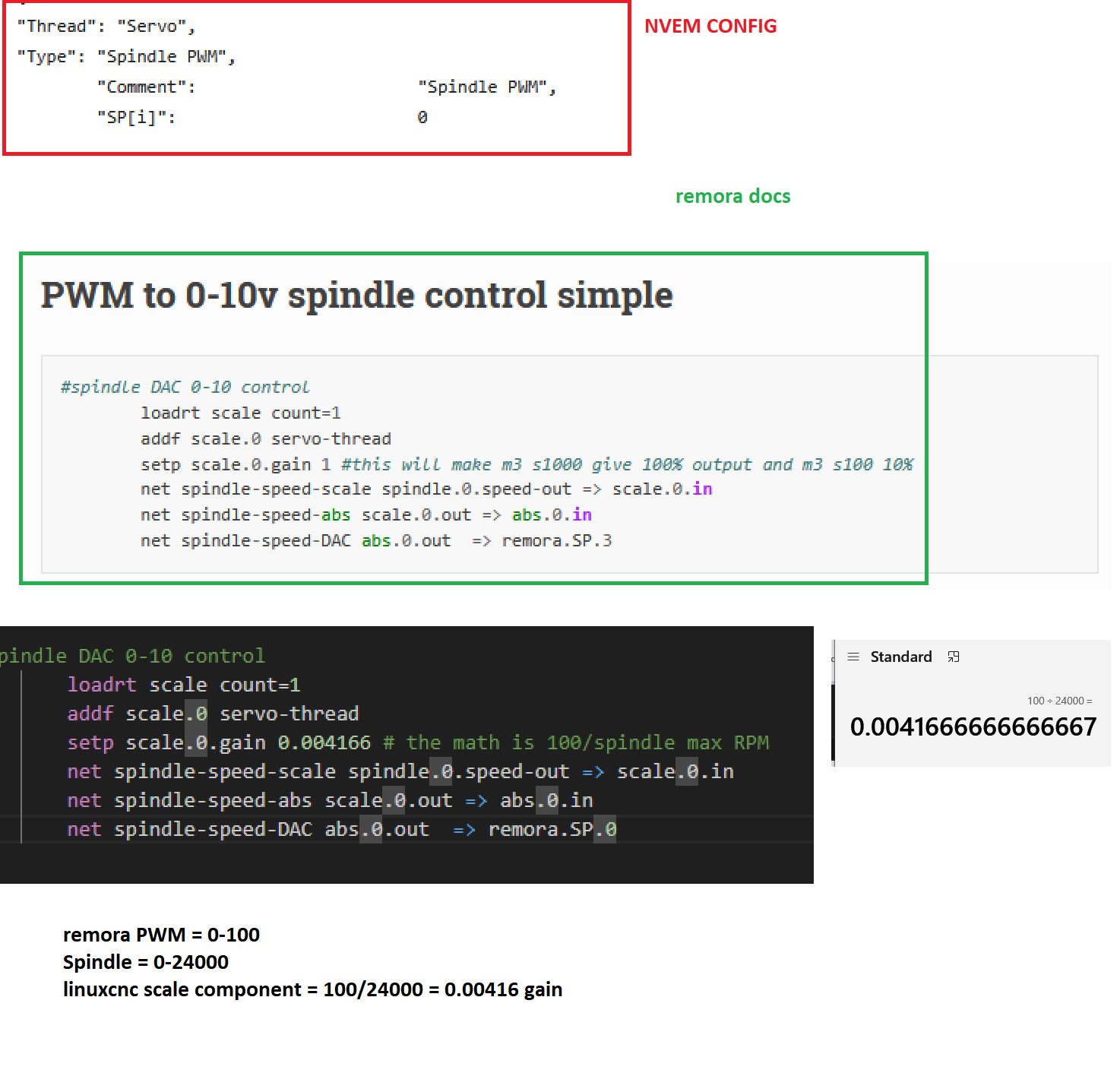

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- pgf

- pgf

06 May 2025 00:44

ISO: Mesa to router interface board was created by pgf

ISO: Mesa to router interface board

Category: Driver Boards

- cakeslob

- cakeslob

06 May 2025 00:33

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- cakeslob

- cakeslob

06 May 2025 00:24

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- PCW

06 May 2025 00:21

Replied by PCW on topic mesa 7i73 4x8 keypad problems on KEY8 input

mesa 7i73 4x8 keypad problems on KEY8 input

Category: Driver Boards

- tommylight

06 May 2025 00:12

Replied by tommylight on topic Bridgeport VMC760 retrofit

Bridgeport VMC760 retrofit

Category: Milling Machines

- rodw

06 May 2025 00:11

Replied by rodw on topic Zero Pierce delay After pierce Only

Zero Pierce delay After pierce Only

Category: Plasmac

Time to create page: 1.029 seconds