Z homed DRO red !

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

I want a new gmoccapy

After homing Z DRO remains in red !!??

I'm wrong or there is a bug ?

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1930

- Thank you received: 394

Norbert

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

Yes original .what are the result with original lathe screen?

If we use sim gmoccapy then no problem .

If we use step wizard or pncconf then this problem .

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1930

- Thank you received: 394

I made a config with stepconf, using 2.7, I started that config and homed the machine: No Problem

I changed over to master and started the same config "it is then converted to 2.8 style": No problem.

Post your config!

Norbert

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

I like very much gmoccapy . We work on two lathe and a milling machine.

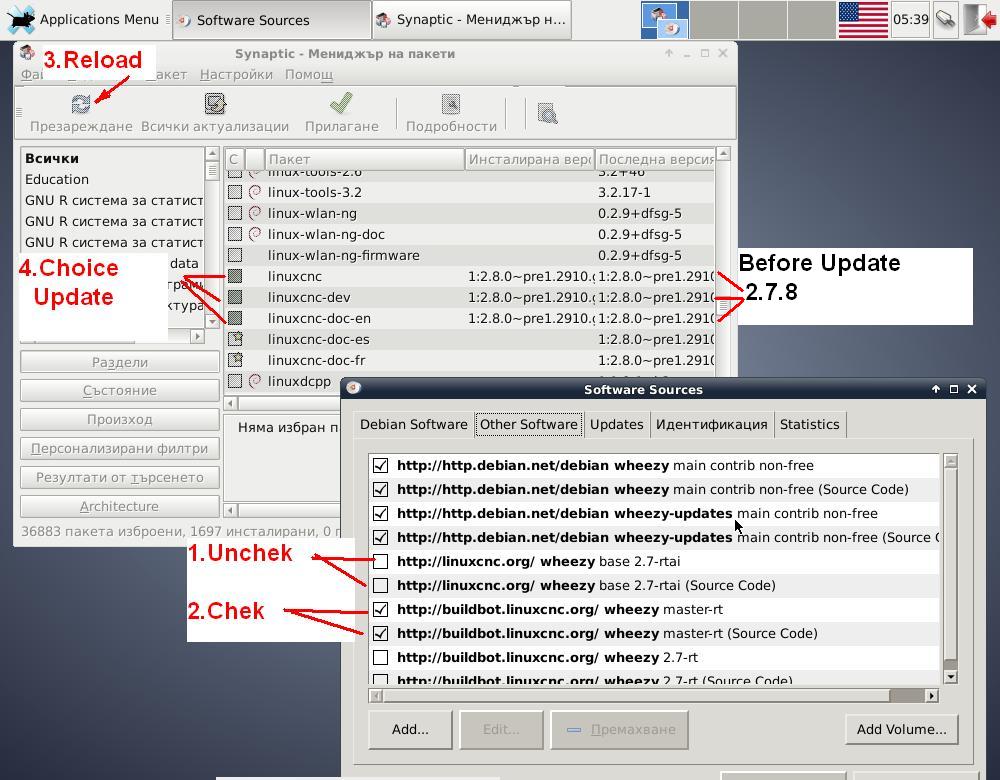

I want to use function "tool wear" in tool table . Therefore upgraded 2.7.8 => 2.8 .

Please see,done properly ?

Then I made configuration (applied)

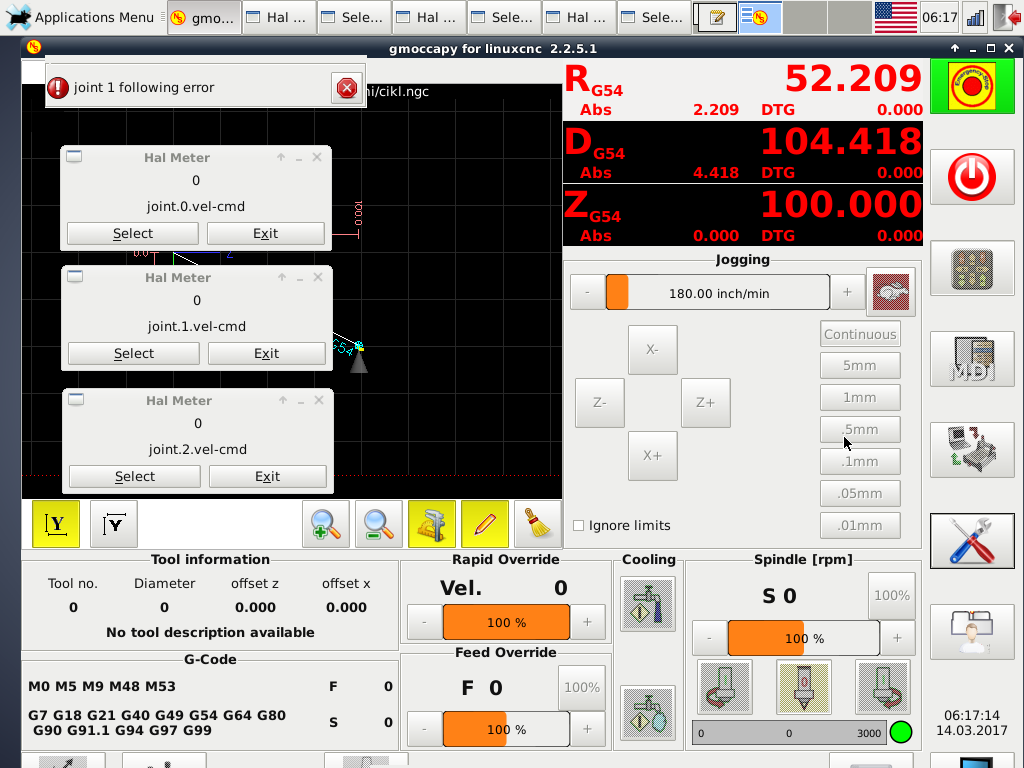

P.S. After homing pin joint.0.homed = 1 , pin joint.1.homed = 0 !!??

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11669

- Thank you received: 3933

KINSTYPE=BOTHThere have been a few changes in Master to integrate the joint axis code that had some impact on Gmocappy which were only fixed recently. When I was trying to solve a now fixed bug, I had a red axis a couple of times....

Removing the kinstype=both means that individual joint mode is disabled but that should not be an issue on a lathe.

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

[KINS]

JOINTS = 2

KINEMATICS = trivkins coordinates=XZ

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1930

- Thank you received: 394

A lathe is a identity kinematics, so you need 3 joints, X being joint 0 and Z being joint 2.

Joint 1 is unused and does not need to be in your ini file.

Change joints to 3 and rename your joint 1 to joint 2.

After that the dro problem should be gone.

Norbert

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

I did this,but there is another problem .This is config real machine :Change joints to 3 and rename your joint 1 to joint 2.

ini:

JOINTS = 3

KINEMATICS = trivkins coordinates=XZ

[TRAJ]

COORDINATES = X Z

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_LINEAR_VELOCITY = 3.00

MAX_LINEAR_VELOCITY = 30.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_WITH_SPINDLE_ON = 1

#********************

# Joint 0

[JOINT_0]

#********************

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 5.0

MAX_VELOCITY = 30.0

MAX_ACCELERATION = 450.0

P = 7.0

I = 0.001

D = 0.0001

FF0 = 0.0

FF1 = 0.002

FF2 = 0.0002

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -1000.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -250.0

MAX_LIMIT = 70.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 10.000

HOME_LATCH_VEL = 1.000

HOME_FINAL_VEL = 1.000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 0

# Axis X

#********************

[AXIS_X]

MAX_VELOCITY = 30.0

MAX_ACCELERATION = 450.0

MIN_LIMIT = -250.0

MAX_LIMIT = 70.0

#********************

# Joint 2

[JOINT_2]

#********************

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 5.0

MAX_VELOCITY = 30.0

MAX_ACCELERATION = 450.0

P = 6.0

I = 0.001

D = 0.0001

FF0 = 0.0

FF1 = 0.002

FF2 = 0.0002

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -1000.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -270.0

MAX_LIMIT = 830.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -10.000

HOME_LATCH_VEL = -1.000

HOME_FINAL_VEL = 1.000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

# Axis Z

#********************

[AXIS_Z]

MAX_VELOCITY = 30.0

MAX_ACCELERATION = 450.0

MIN_LIMIT = -270.0

MAX_LIMIT = 830.0

#********************

# Spindle

#********************

[SPINDLE_9]

# P = 0.0

# I = 0.0

# D = 0.0

# FF0 = 1.0

# FF1 = 0.0

# FF2 = 0.0

# BIAS = 0.0

# DEADBAND = 0.0

MAX_OUTPUT = 1500.0

ENCODER_SCALE = 4096.0

OUTPUT_SCALE = 1500

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 1500

hal

# JOINT X

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [JOINT_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [JOINT_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [JOINT_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd joint.0.motor-pos-cmd

net x-enable joint.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [JOINT_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => joint.0.motor-pos-fb

net x-index-enable joint.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net home-x => joint.0.home-sw-in

net both-x => joint.0.neg-lim-sw-in

net both-x => joint.0.pos-lim-sw-in

#*******************

# JOINT Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [JOINT_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [JOINT_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [JOINT_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout1

net z-pos-cmd joint.2.motor-pos-cmd

net z-enable joint.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [JOINT_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.01.position

net z-vel-fb <= hm2_5i25.0.encoder.01.velocity

net z-pos-fb => joint.2.motor-pos-fb

net z-index-enable joint.2.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net home-z => joint.2.home-sw-in

net min-z => joint.2.neg-lim-sw-in

net max-z => joint.2.pos-lim-sw-in

In this configuration, when pressed the button -X or +X normal move

but when pressed the button -Z or +Z joint.2.vel-cmd =0 joint.1.vel-cmd = 3

[ jog speed = 180mm/min ( and another problem show sometimes inch/min ) ]

joint.1 error !!!!!!??????

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

ini :

[KINS]

JOINTS = 2

KINEMATICS = trivkins coordinates=XZ

I have my lathe set up as 2 joints and use the 2.8 version of LinuxCNC.

I use the Touchy GUI and have noticed that I don't get a "homed" indicator in the GUI for the Z axis.

This looks like exactly the same problem. (Except it isn't really a problem for me, and I have ignored it).

I will try some experiments tonight to see if I can see the problem.

Please Log in or Create an account to join the conversation.