SK Commander VFD Parms

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

19 Mar 2023 03:59 #267058

by rodw

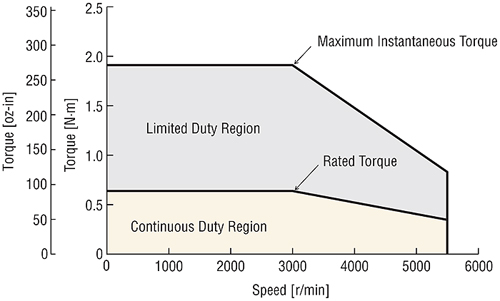

I would expect servo motor torque curves to follow something like this

Ref: www.orientalmotor.com/servo-motors/techn...-motor-features.html

You can see here the torque is constant regardless of speed until it gets to 3000 rpm

The clearpath torque curves follow the more normal form of a stepper motor.

Replied by rodw on topic SK Commander VFD Parms

It looks like they could still be Tommy based on the torque curves.@Snowwy,

Can you please check the torque charts for the "servos" you got?

Sorry, but i still get very P.O. at "clearpath servos" as i am sure they were selling closed loop steppers as servos a few years back.

Thank you.

I would expect servo motor torque curves to follow something like this

Ref: www.orientalmotor.com/servo-motors/techn...-motor-features.html

You can see here the torque is constant regardless of speed until it gets to 3000 rpm

The clearpath torque curves follow the more normal form of a stepper motor.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Away

- Moderator

-

Less

More

- Posts: 2529

- Thank you received: 858

20 Mar 2023 11:27 - 20 Mar 2023 11:28 #267133

by snowgoer540

Replied by snowgoer540 on topic SK Commander VFD Parms

I was under the impression (maybe from a John Saunders NYCCNC video back in the day) that the SK model was designed to be a drop in replacement for a stepper, and the torque curves were designed to be similar to steppers on purpose (the video below does mention this).

If you look at the HD models, the torque curve is probably more what you both seem to expect, but at quite a price difference.

Anyways, this video is worth a watch:

At any rate they're definitely servos:

teknic.com/products/clearpath-brushless-dc-servo-motors/

If you look at the HD models, the torque curve is probably more what you both seem to expect, but at quite a price difference.

Anyways, this video is worth a watch:

Warning: Spoiler!

At any rate they're definitely servos:

teknic.com/products/clearpath-brushless-dc-servo-motors/

Last edit: 20 Mar 2023 11:28 by snowgoer540.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21098

- Thank you received: 7205

20 Mar 2023 11:47 #267136

by tommylight

Replied by tommylight on topic SK Commander VFD Parms

I can not fathom why would they or anyone make servo systems imitate a stepper system, seems unreasonable on many levels and waste of potential.

Sorry for steering off topic, and thank you, all.

Sorry for steering off topic, and thank you, all.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Away

- Moderator

-

Less

More

- Posts: 2529

- Thank you received: 858

20 Mar 2023 12:44 #267142

by snowgoer540

Replied by snowgoer540 on topic SK Commander VFD Parms

He did loosely cover that in the video I linked "high torque at low speed to allow driving lower speed applications without gearing". Not saying he's right or wrong, just citing what he said.

I've been impressed so far, with both their product and their customer service. They spent way more time than they had to on the phone with me (they called me, which is rare) answering my probably-silly questions about tuning parameters they didn't write (Tormach did), among other things.

The best part of the current CNC scene is that there are a myriad of products and you get to choose which products you want to consume, and from which business you want to consume them from.

I've been impressed so far, with both their product and their customer service. They spent way more time than they had to on the phone with me (they called me, which is rare) answering my probably-silly questions about tuning parameters they didn't write (Tormach did), among other things.

The best part of the current CNC scene is that there are a myriad of products and you get to choose which products you want to consume, and from which business you want to consume them from.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

20 Mar 2023 13:01 #267146

by rodw

I'm not saying they aren't good motors but its a misleading analysis designed to keep the so called inferior stepper in the resonance zone.

Glosses over and ignores a lot of engineering on the stepper side..

I looked at one of our motors we did detailed engineering for. A nema 24 capable of 60 m/min rapids with a 3:1 reduction and on the X axis, its maximum power requirement of 9.81 watts. It would be rare for a motor that size to need 100 watts. We overrate steppers using Lam's step boost technology., not underrate them and we never loose steps.

Replied by rodw on topic SK Commander VFD Parms

X 2I can not fathom why would they or anyone make servo systems imitate a stepper system, seems unreasonable on many levels and waste of potential.

Sorry for steering off topic, and thank you, all.

I'm not saying they aren't good motors but its a misleading analysis designed to keep the so called inferior stepper in the resonance zone.

Glosses over and ignores a lot of engineering on the stepper side..

I looked at one of our motors we did detailed engineering for. A nema 24 capable of 60 m/min rapids with a 3:1 reduction and on the X axis, its maximum power requirement of 9.81 watts. It would be rare for a motor that size to need 100 watts. We overrate steppers using Lam's step boost technology., not underrate them and we never loose steps.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

20 Mar 2023 13:16 #267147

by rodw

Replied by rodw on topic SK Commander VFD Parms

Clearly they have been designed as a drop in replacement dfor steppers. If a machine was engineered from scratch, thye would have significant limiting factors. It would be a rare case where gearing is not required in any motion application. Sometimes its not obvious as its driving a ballscrew. Hight torque at low speed is advantageous for plasma as it alows faster Accelleration. A more conventional servo has constant torque across the whole rev range. We don't need 3000-5000 rpm servos so gearing down make sense to amplify that torque at all speeds. Also the more conventional servo can handle 200-300% over rating for short periods (as the graph I shared shows), We only need 30 ms to get to 10 m/sec at 0.5 G accelleration so that works to advantage.He did loosely cover that in the video I linked "high torque at low speed to allow driving lower speed applications without gearing". .

Please Log in or Create an account to join the conversation.

Time to create page: 0.082 seconds